5.18

BODY / STEERING / SUSPENSION

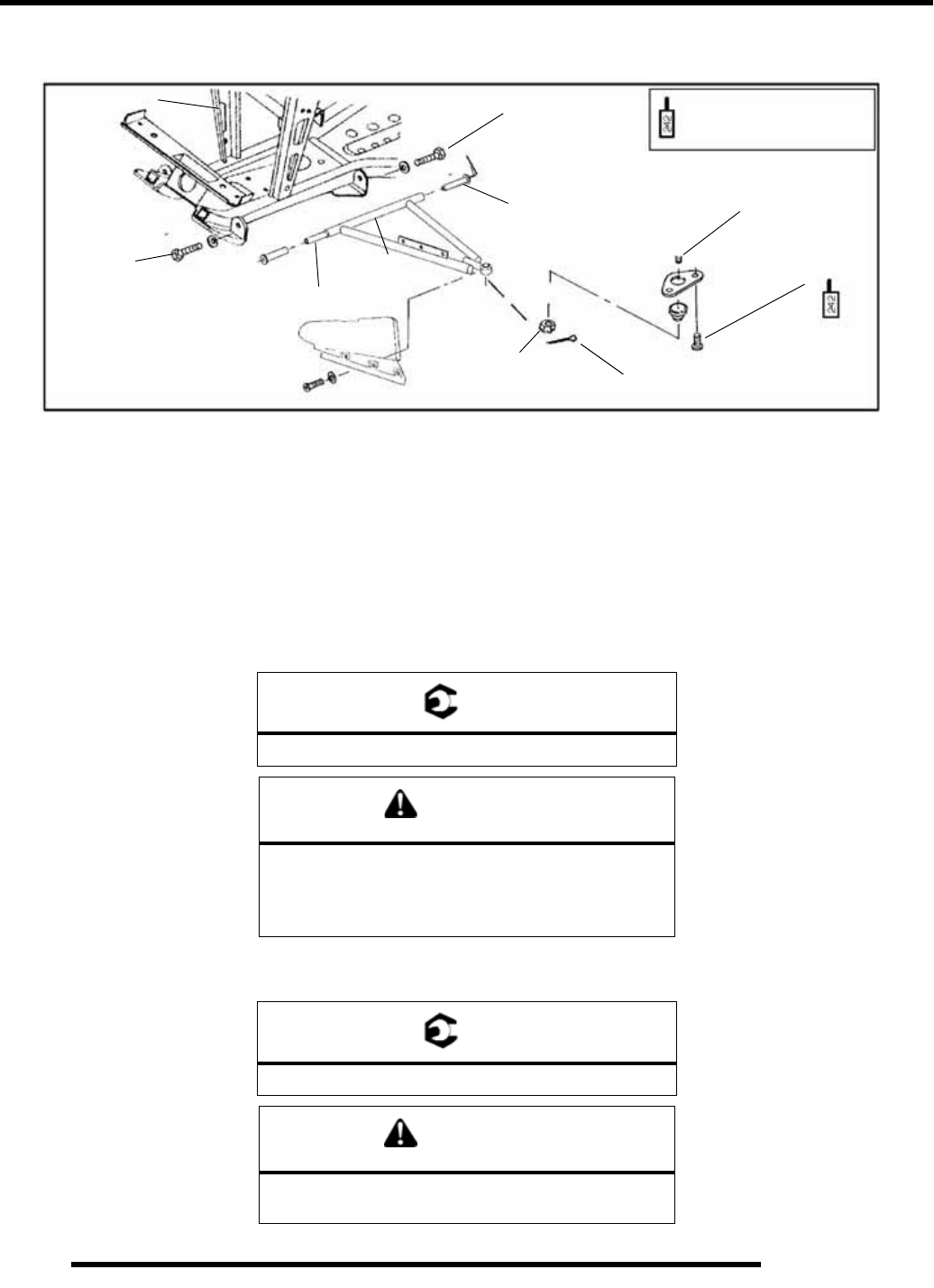

A-Arm Replacement

1. Elevate and safely support vehicle with weight removed from front wheel(s).

2. Remove cotter pin from ball joint stud at wheel end of A-arm and loosen nut until it is flush with end of stud.

3. Using a soft face hammer, tap nut to loosen A-arm from bolt. Remove nut and A-arm from hub strut assembly.

4. Loosen two bolts on A-arm tube by alternating each about 1/3 of the way until A-arm can be removed.

5. Examine A-arm shaft. Replace if worn. Discard hardware.

6. Insert A-arm shaft into new A-arm.

7. Install CV joint shields.

8. Install new A-arm assembly onto vehicle frame. Torque new bolts to specification.

9. Attach A-arm to hub strut assembly. Tighten ball joint nut to specification. If cotter pin holes are not aligned, tighten nut

slightly to align. Install a new cotter pin with open ends toward rear of machine. Bend both ends in opposite directions around nut

= T

A-Arm Bolt Torque: 30 ft. lbs. (41.4 Nm)

WARNING

The locking features on the existing bolts were

destroyed during removal. DO NOT reuse old

bolts. Serious injury or death could result if

fasteners come loose during operation.

= T

Ball Joint Nut Torque: 25 ft. lbs. (35 Nm)

WARNING

Upon A-arm installation completion, test vehicle at

low speeds before putting into regular service.

30 ft.lbs. (41 Nm)

A-arm Shaft

Apply Loctite 242

to the bolt threads.

Vehicle Frame

Bolt - 30 ft.lbs. (41 Nm)

Bushing

Ball Joint Stud

8 ft.lbs. (11 Nm)

Cotter Pin - (Install New)

25 ft.lbs. (35 Nm)

A-Arm Tube