6.17

CLUTCH SYSTEM

6

Button To Tower Clearance Inspection

1. Inspect for any clearance between spider button to tower.

If clearance exists, replace all buttons and inspect surface

of towers. See “Spider Removal” procedure.

2. Inspect sheave surfaces. Replace the entire clutch as an

assembly if worn, damaged or cracked.

Shift Weight Inspection

1. If clutch is not disassembled, inspect as shown, using a

clutch holding tool to compress the moveable sheave. The

contact surface of the weight should be smooth and free of

dents or gall marks. Remove shift weight bolts and

weights.

2. Inspect the weight pivot bore and pivot bolts for wear or

galling. If weights or bolts are worn or broken, replace in

sets of three with new bolts.

NOTE: A damaged shift weight is usually caused by

a damaged or stuck roller in the spider assembly.

See roller inspection, see “Roller, Pin, and Thrust

Washer Inspection”.

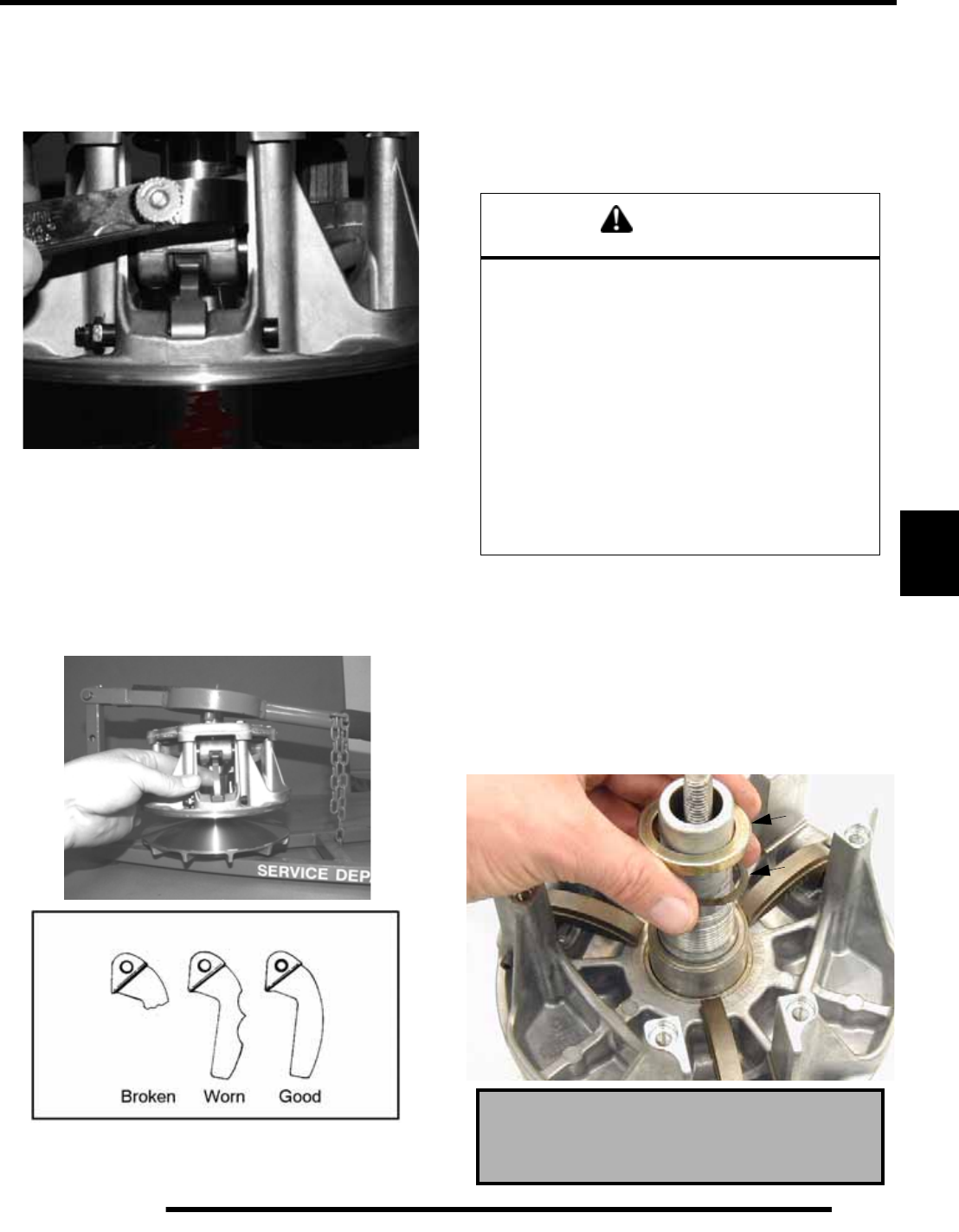

Drive Clutch Inspection

NOTE: Remove cover, spring, and spider following

instructions for drive clutch removal, then proceed

as follows:

1. Remove moveable sheave spacer sleeve (1) and the thrust

washer (2). Visually inspect the washer for damage.

Measure the thickness and compare to specification.

Replace if worn or damaged.

Button to Tower Clearance: .000-.001

WARNING

The clutch assembly is a precisely balanced unit.

Never replace parts with used parts from another

clutch assembly!

All PVT maintenance or repairs should be

performed only by a certified Polaris Master Service

Dealer (MSD) technician who has received the

proper training and understands the procedures

outlined in this manual.

Because of the critical nature and precision

balance incorporated into the PVT system, it is

absolutely essential that no attempt at

disassembly or repair be made without factory

authorized special tools and service

procedures.

Thrust Washer Thickness

Standard: .030, (.76mm)

Service Limit: .025, (.64mm)

1

2