3.33

ENGINE

3

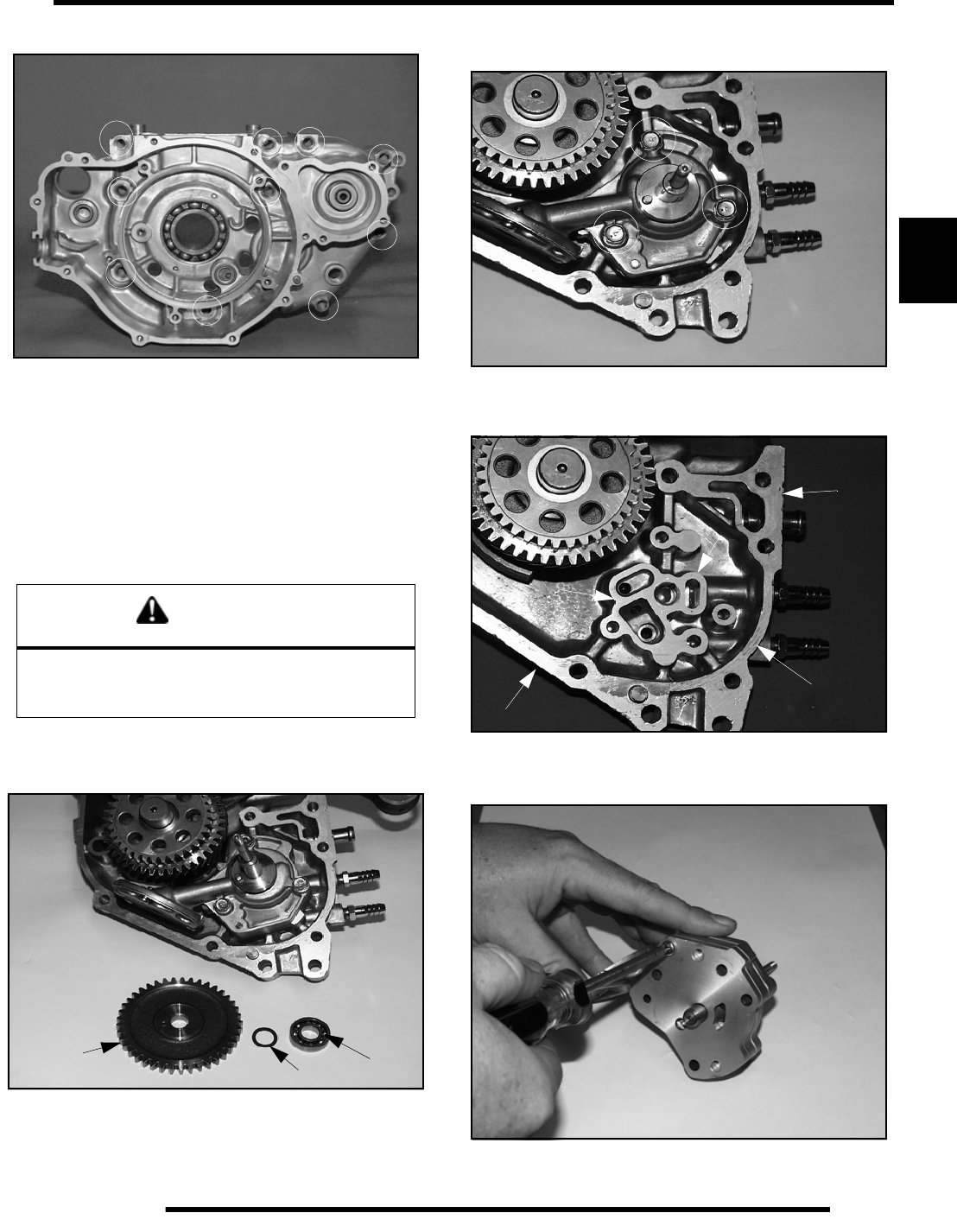

Crankcase Separation

1. Remove flange bolts (10) from magneto side crankcase

evenly in a criss-cross pattern.

2. Separate crankcase by tapping with a soft faced hammer in

reinforced areas.

3. Tap lightly on balancer gear with a brass drift through the

hole in the crankcase if necessary, to ensure the balancer

shaft stays in the PTO side crankcase. Watch the gap along

the crankcase mating surface and separate the crankcase

evenly. It may also be necessary to tap the oil pump shaft

lightly to separate the crankcase.

4. Remove the Mag (RH) crankcase from the PTO case.

Oil Pump Removal/Inspection

1. Remove pump shaft bearing (A) and thrust washer (B)

from pump shaft.

2. Remove (2) bolts holding pump drive gear (C).

3. Inspect drive gear teeth for cracks, damage or excessive

wear.

4. Remove three oil pump retaining bolts and pump.

5. Inspect mating surface of crankcase and oil pump. Check

for nicks, burrs, or surface irregularities.

6. Remove the three screws and strainer screen from pump.

7. Clean screen thoroughly.

8. Remove pump body screw and feed chamber cover.

CAUTION

Do not strike the oil pump shaft at an angle or the

shaft may bend, causing irreparable damage. Tap

only lightly on the pump shaft if necessary.

C

B

A