3.51

ENGINE

3

RECOIL

Recoil Disassembly/Inspection

Replace any parts found to be worn or damaged.

1. Remove bolts and recoil from the engine.

2. Pull recoil rope (if applicable) so it is extended

approximately 12-18" (30-46cm). Check handle c-ring for

proper tension, and the handle for cracks or damage which

may allow water or dirt to enter the recoil housing through

the rope.

3. Remove handle from the rope and allow spring tension on

recoil to relax.

NOTE: The handle must seal tightly on the recoil

housing to prevent water from entering.

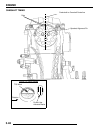

4. Remove center bolt from recoil friction plate (A).

5. Inspect plate for wear or damage. Inspect plate friction

spring for wear, damage, and proper tension. The spring

should fit tightly on friction plate.

6. Remove ratchet pawl with spring and inspect. Replace

spring or ratchet pawl if worn, broken, or damaged.

NOTE: Long arm of spring engages reel. Short end

against pawl.

7. Hold reel firmly in housing. Pull rope handle until 12-18"

(30-46cm) of rope is exposed, and hold reel in place.

8. Place rope in notch on outer edge of reel. Release tension

on hub and allow reel to unwind approximately 6-7 turns

until spring tension is released.

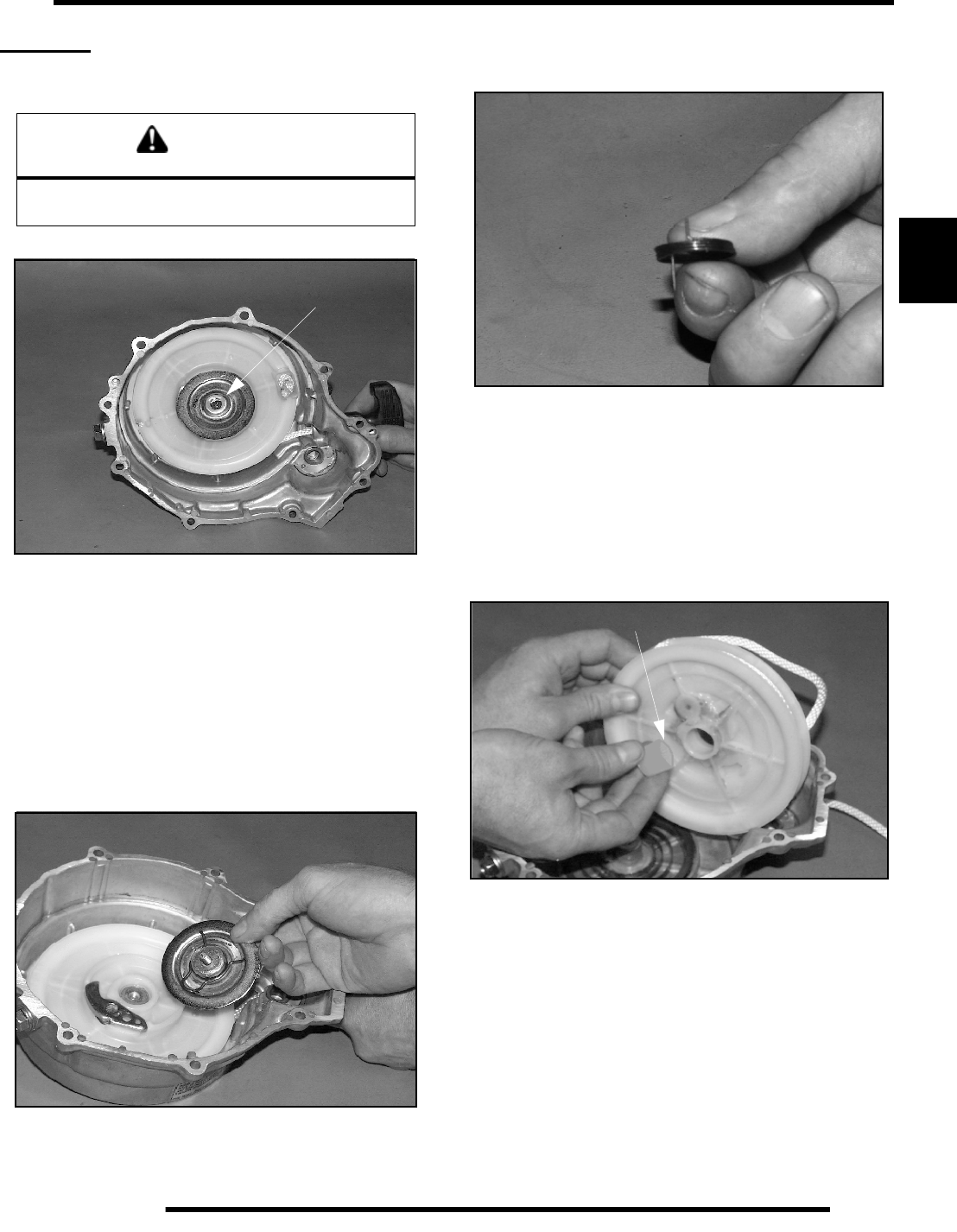

9. Slowly and carefully remove reel from recoil housing

making sure the spring remains in the housing. Inspect the

reel hub and bushing (A) for wear.

10. Unwind rope and inspect for cuts or abrasions.

11. Inspect drive tab on hub return spring for damage. To

remove hub return spring, hold outer coils in place with one

hand and slowly remove spring one coil at a time from the

inside out.

12. Pull knot out of recoil reel. Untie knot. Remove rope from

reel.

CAUTION

The recoil is under spring tension. A face shield and

eye protection is required during this procedure.

A

A