70

Reassembly

KohlerEngines.com 20 690 01 Rev. F

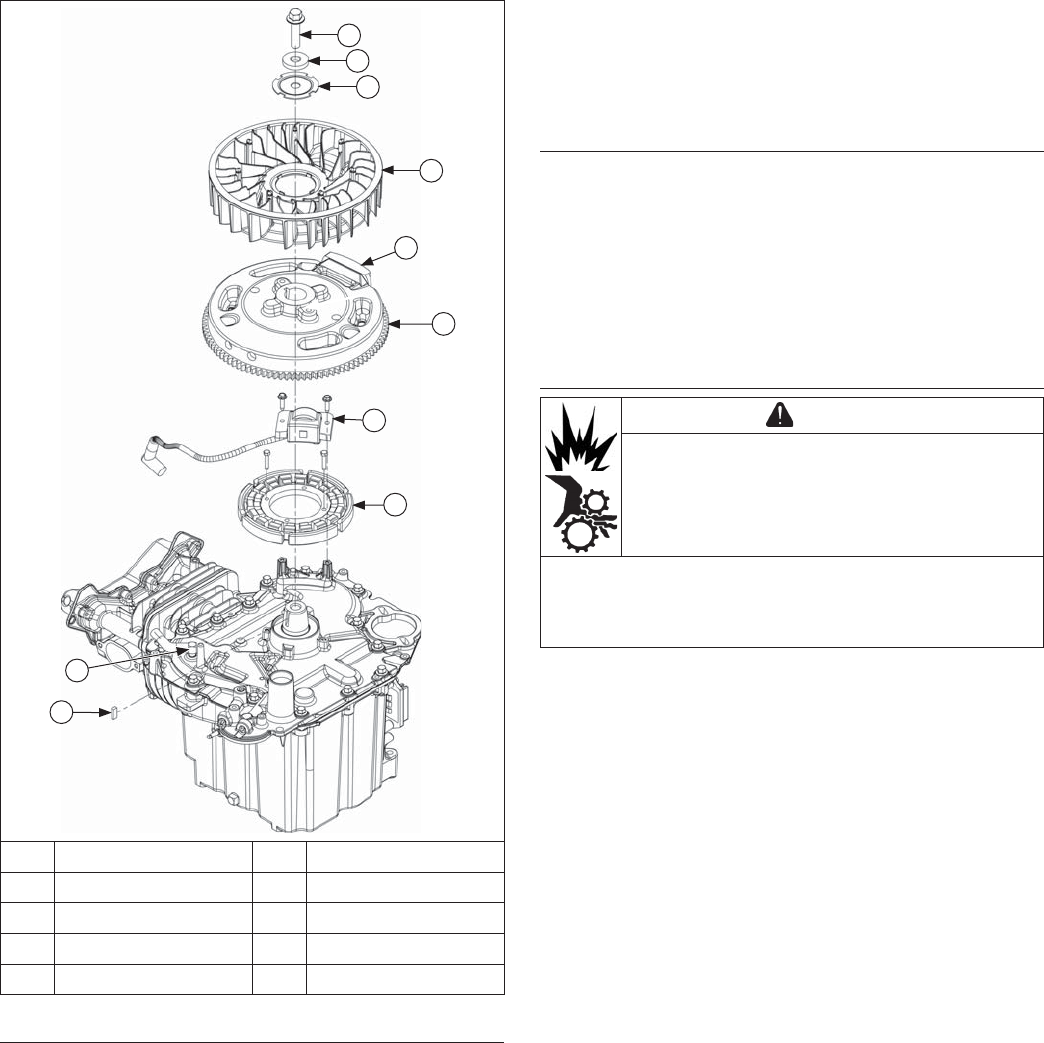

Flywheel/Ignition Components

G

F

H

I

J

B

C

D

E

A

A Flywheel Screw B Washer

C Fan Mounting Plate D Fan

E Magnet F Flywheel

G Ignition Module H Stator

I Flywheel Key J Pulse Line Fitting

Install Stator and Wiring Harness

Install Stator

1. Position stator onto mounting bosses so leads lay in

channel and recess of closure plate. They will

become captured when blower housing is installed.

If a clamp was used to retain leads, remove screw in

No. 13 location and install clamp. Hold clamp in

position and torque screw to 24.5 N·m (216 in. lb.)

2. Install two screws to secure stator and torque to

6.0 N·m (55 in. lb.), into new holes, or 4.0 N·m

(35 in. lb.), into used holes.

Install Wiring Harness

Check locking tang on terminal of violet B+ wiring

harness lead is angled upward. Insert terminal into

center location of rectifi er-regulator plug connector until

it locks into place. If not already inserted, two AC leads

from stator go in outer locations.

Install Pipe Plug or Fitting and Pulse Line for Fuel

Pump

1. Apply pipe sealant with Tefl on

®

(Loctite

®

PST

®

592™

Thread Sealant or equivalent), to 1/8” pipe plug or

90° fi tting (as equipped). Install and tighten into

tapped vacuum port of closure plate. Torque plug to

4.5-5.0 N·m (40-45 in. lb.). Turn outlet of a fi tting to

8 o’clock position.

2. If a fi tting is used, connect fuel pump pulse line and

secure with clamp. If fuel pump is attached to air

cleaner base, do not connect pulse line at this time.

Install Fan and Flywheel

CAUTION

Damaging Crankshaft and Flywheel can

cause personal injury.

Using improper procedures can lead to broken

fragments. Broken fragments could be thrown from

engine. Always observe and use precautions and

procedures when installing fl ywheel.

NOTE: Before installing fl ywheel make sure crankshaft

taper and fl ywheel hub are clean, dry and

completely free of lubricants. Presence of

lubricants can cause fl ywheel to be over

stressed and damaged when mounting screw is

torqued to specifi cation.

NOTE: Make sure fl ywheel key is installed properly in

keyway. Flywheel can become cracked or

damaged if key is not properly installed.

NOTE: Always use a fl ywheel strap wrench or fl ywheel

holding tool to hold fl ywheel when tightening

fl ywheel fastener. Do not use any type of bar or

wedge between cooling fi ns or fl ywheel ring

gear, as these parts could become cracked or

damaged.

1. Install appropriate key into crankshaft keyway.

Based on crankshaft keyway style, use either a

woodruff or straight key. Make sure key is fully

seated.

2. Install fl ywheel onto crankshaft aligning keyway with

key. Be careful not to shift or unseat key.

3. Position fan onto fl ywheel, so locating pins drop into

corresponding recesses.

4. Install fan mounting plate onto fan, aligning four

cutouts, followed by heavy fl at washer and screw.

5. Use a fl ywheel strap wrench or holding tool to hold

fl ywheel and torque screw. For an M10 screw, torque

to 66.5 N·m (49 ft. lb.). For an M12 screw, torque to

88.0 N·m (65 ft. lb.).