26

Fuel System

KohlerEngines.com 20 690 01 Rev. F

1. Place throttle control into idle or slow position. Adjust

low idle speed to 1200 RPM. Follow Low Idle Speed

(RPM) Adjustment.

2. Low idle fuel needle(s) setting: place throttle into idle

or slow position.

a. Turn 1 low idle fuel adjusting needle out

(counterclockwise) from preliminary setting until

engine speed decreases (rich). Note position of

needle. Now turn adjusting needle in (clockwise).

Engine speed may increase, then it will decrease

as needle is turned in (lean). Note position of

needle. Set adjusting needle midway between

rich and lean settings.

b. Repeat procedure on other low idle adjustment

needle (two-barrel carburetor only).

3. Recheck/adjust Low Idle Speed (RPM) to specified

setting.

High Speed (RPM) Adjustment

1. With engine running, move throttle control to fast.

2. Turn inner adjustment screw outward to decrease, or

inward to increase RPM speed. Courage singles

require loosening screws on speed control bracket

and sliding towards carburetor to lower and away

from carburetor to increase speed.

Carburetor Servicing

NOTE: Main and slow jets are fi xed and size specifi c

and can be removed if required. Fixed jets for

high altitudes are available.

● Inspect carburetor body for cracks, holes, and other

wear or damage.

● Inspect fl oat for cracks, holes, and missing or

damaged fl oat tabs. Check fl oat hinge and shaft for

wear or damage.

● Inspect fuel inlet needle and seat for wear or damage.

● Inspect spring loaded choke plate to make sure it

moves freely on shaft.

1. Perform removal procedures for appropriate air

cleaner and carburetor outlined in Disassembly.

2. Clean exterior surfaces of dirt or foreign material

before disassembling carburetor. Remove bowl

retaining screws, or solenoid assembly on most

single cylinder engines, and carefully separate fuel

bowl from carburetor. Do not damage fuel bowl

O-rings. Transfer any remaining fuel into an

approved container. Save all parts. Fuel can also be

drained prior to bowl removal by loosening/removing

bowl drain screw.

3. Remove fl oat pin (some carburetors may have a

screw which requires removal), and inlet needle.

Seat for inlet needle is not serviceable and should

not be removed.

4. Clean carburetor bowl and inlet seat areas as

required.

5. Carefully remove main jets from carburetor. For

two-barrel carburetors, note and mark jets by

location for proper reassembly. Main jets may be

size/side specifi c. After main jets are removed, on

some carburetors, main nozzles can be removed

through bottom of main towers. Note orientation/

direction of nozzles. End with 2 raised shoulders

should be out/down adjacent to main jets. Save

parts for cleaning and reuse.

6. Position of slow jet varies and is removable only on

some styles of carburetors. See correct illustration

for corresponding style of carburetor showing

location. (On two-barrel carburetors, slow jets may

be sized to specifi c side. Mark or tag jets for proper

reassembly. Note small O-ring on bottom of each

jet.) Save parts for cleaning and reuse unless a jet

kit is also being installed. Clean slow jets using

compressed air. Do not use wire or carburetor

cleaner.

Carburetor is now disassembled for appropriate cleaning

and installation of parts in overhaul kit. See instructions

provided with repair kits for more detailed information.

High Altitude Operation

Engines may require a high altitude carburetor kit to

ensure correct engine operation at altitudes above

1219 meters (4000 ft.). To obtain high altitude kit

information or to fi nd a Kohler authorized dealer visit

KohlerEngines.com or call 1-800-544-2444 (U.S. and

Canada).

This engine should be operated in its original

confi guration below 1219 meters (4000 ft.) as damage

may occur if high altitude carburetor kit is installed and

operated below 1219 meters (4000 ft.).

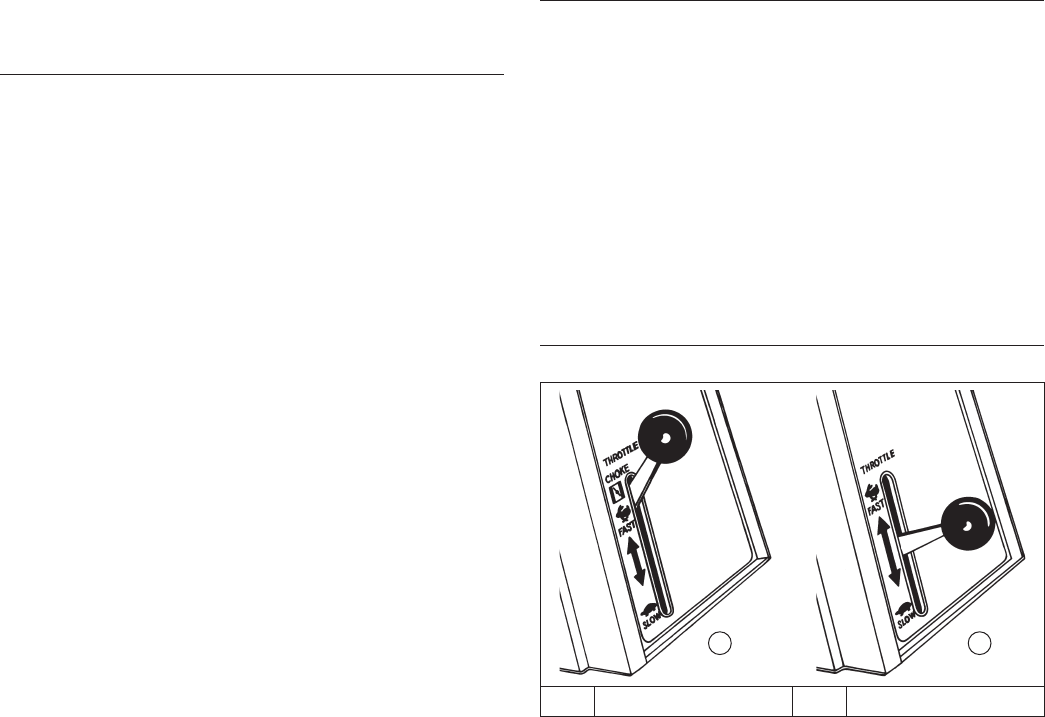

UNITIZED THROTTLE AND CHOKE CONTROL

Some engines are equipped with a unitized throttle and

choke control. This assembly controls choke and engine

speed with a single lever.

Throttle Cable Adjustment

Throttle/Choke Controls Details

BA

A Cold Engine B Warm Engine