30

Fuel System

KohlerEngines.com 20 690 01 Rev. F

Throttle Control Installation

1. Loosen two cable clamp screws on speed control

bracket assembly.

2. Move application throttle control lever to maximum

full (fast) throttle position, and then move it back

3/16" or 4.75 mm. Insert cable boden wire into

throttle control lever on control plate.

3. Position throttle cable under cable clamp.

4. Early Models: Early models use a single alignment

hole to set engine RPM. Align hole in throttle lever

with hole in speed control bracket by inserting a

pencil or 6.35 mm (1/4 in.) drill bit.

Later Models: Later models utilize a new design

control assembly, identifi ed by two opposing

alignment holes (close to throttle lever pivot), instead

of one. Based upon intended high speed (RPM)

setting, throttle cable adjustment must be made

matching hole in control lever with appropriate

alignment hole. Use lower (left side) hole for high-

speed settings 3000 RPM and above. Use upper

(right side) hole for high-speed settings less than

3000 RPM. Move throttle lever to align hole in lever

with appropriate hole in control bracket. Insert a

pencil or a 6.35 mm (1/4 in.) drill bit to hold in

position.

Current Models: Current models use a new control

assembly, identifi ed by three alignment holes (close

to throttle lever pivot). Based upon intended high-

speed (RPM) setting, throttle cable adjustment must

be made by matching hole in control lever with

correct alignment hole. Use appropriate hole for

corresponding high-speed settings. Move throttle

lever to align hole in lever with correct hole in control

bracket. Insert a pencil or a 6.35 mm (1/4 in.) drill bit

to hold in position.

5. Pull on outer shield of throttle control cable to

remove any slack. Tighten cable clamp securely.

6. Move application throttle lever to slow position, then

to full throttle. Check engine control to ensure it

stops against stop screw, which means it is properly

set.

Choke Control Installation

1. Connect choke cable boden wire to engine choke

control lever on speed control bracket assembly.

2. Position choke cable under cable clamp.

3. Push/move choke control to off position in

application panel until it bottoms, then pull it back

approximately 1/16 in.

4. Push on choke cable, ahead of clamp on engine

control plate, until choke lever stops. Do not force.

Then tighten cable clamp screw.

5. Move choke control until it stops (on position). Check

that choke link cannot be moved towards carburetor

by applying fi nger pressure on lower link/lever below

engine control plate. If choke link moves, readjust by

following steps 3 and 4.

6. Push/move choke control in/down until it bottoms.

Choke lever and link should be to right at end of its

travel, with linkage free so engine does not run on

partial choke.

Starting an Engine Equipped with Separate Control

Cables

1. Place throttle control midway between slow and fast

positions. Place choke control into on position.

2. Start engine.

3. For a Cold Engine – Gradually return choke control

to off position after engine starts and warms up.

Engine/equipment may be operated during warm up

period, but it may be necessary to leave choke

partially on until engine warms up.

4. For a Warm Engine – Return choke to off position as

soon as engine starts.

Changing High Speed (RPM) on Engines with

Separate Controls (Increase or Decrease RPM)

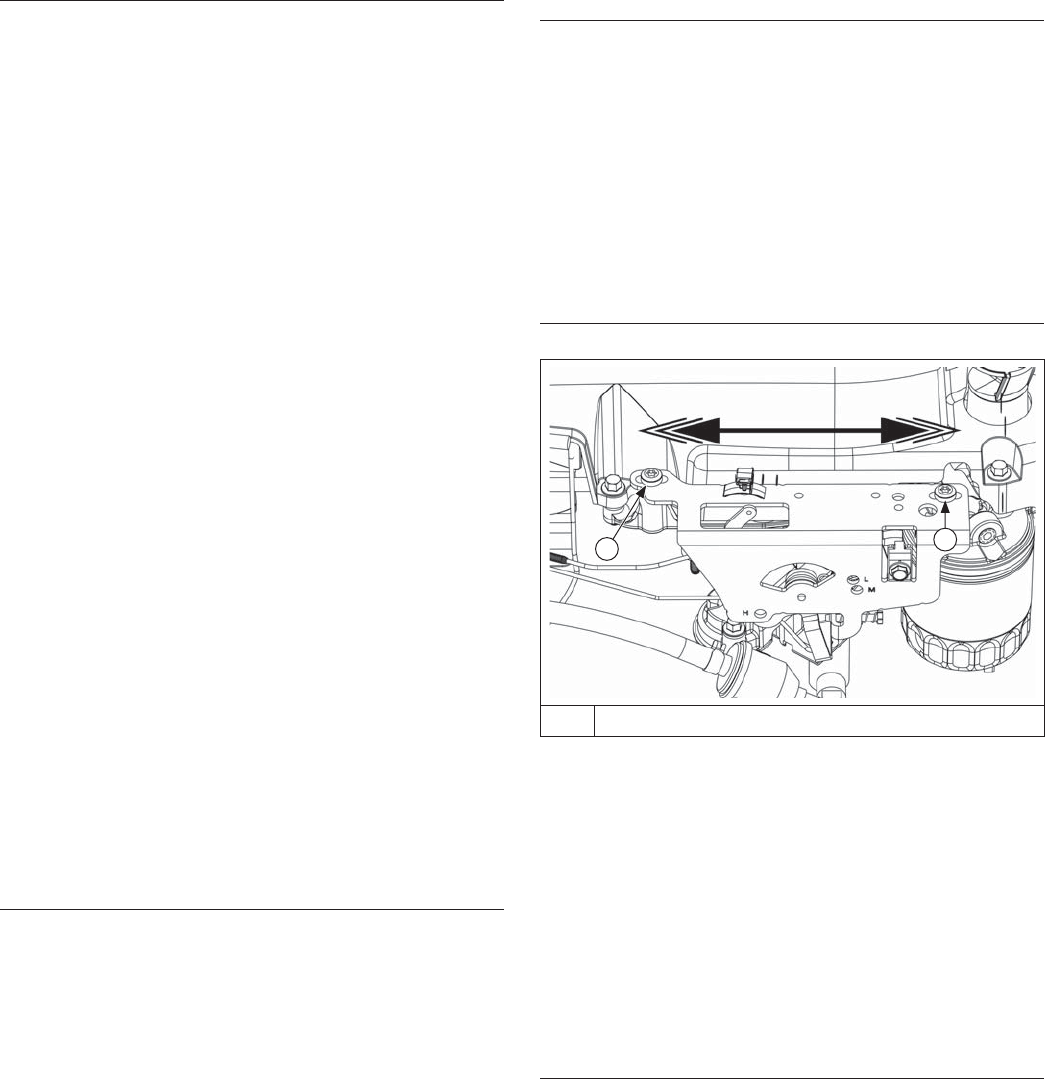

Speed Control Bracket Details

A

A

A Speed Control Bracket Mounting Screw

1. Check that governor spring and installation matches

intended high speed RPM operating range.

2. Start engine, move application throttle lever to full

throttle/fast, and loosen mounting screws of main

speed control bracket to allow repositioning.

3. To increase RPM: Move speed control bracket,

towards carburetor. To decrease RPM: Move speed

control bracket, away from carburetor. Check RPM

with a tachometer and tighten screws when correct

setting has been obtained.

4. To ensure that RPM has been obtained, move

throttle lever to low idle/slow then back to full throttle/

fast position and check RPM with a tachometer.

Setting Low Idle RPM

1. Move application control to slow position.

2. Using a tachometer, check RPM. Then, using a

screwdriver, turn low idle speed screw inward

(clockwise) to increase RPM, and outward

(counterclockwise) to lower RPM.