27

Fuel System

20 690 01 Rev. F KohlerEngines.com

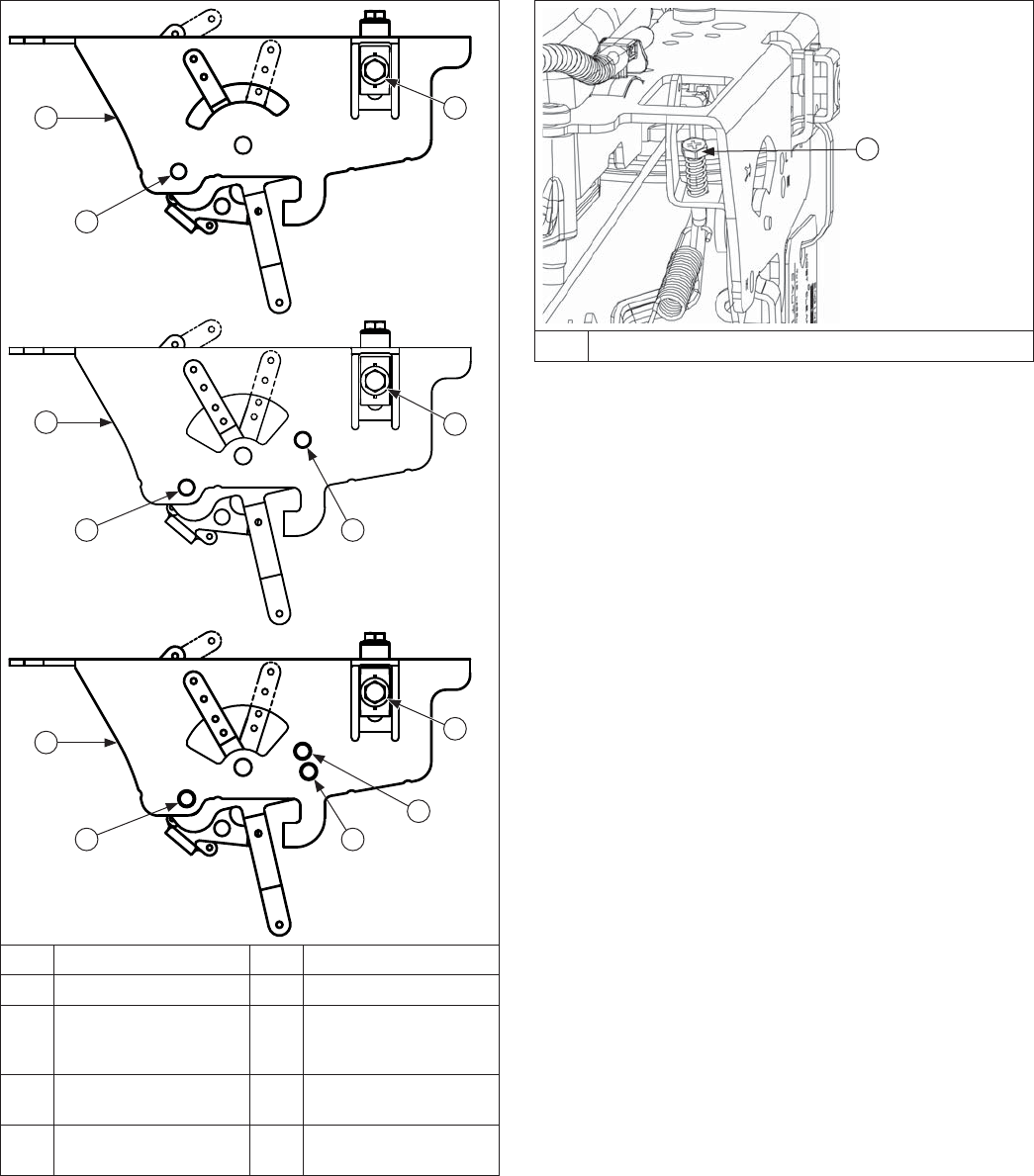

Choke Adjusting Screw Details

A

A Choke Adjusting Screw

NOTE: Choke is placed ON by moving throttle control

slightly past fast position. If throttle control does

not have a designated choke ON position, be

sure to leave suffi cient throttle control travel past

fast position. This will enable choke to be placed

ON.

1. Loosen control cable clamp.

2. Place throttle control lever of equipment into fast or

high speed position. Actuating tab of choke lever

should be just below end of choke adjusting screw.

3. Early Models: Early models use a single alignment

hole to set engine RPM. Align hole in throttle lever

with hole in speed control bracket by inserting a

pencil or 6.35 mm (1/4 in.) drill bit.

Later Models: Later models use a new control

assembly, identifi ed by two opposing alignment

holes (close to throttle lever pivot), instead of one.

Based upon intended high-speed (RPM) setting,

throttle cable adjustment must be made by matching

hole in control lever with correct alignment hole. Use

lower (left side) hole for high-speed settings above

3000 RPM. Use upper (right side) hole for high-

speed settings lower than 3000 RPM. Move throttle

lever to align hole in lever with correct hole in control

bracket. Insert a pencil or a 6.35 mm (1/4 in.) drill bit

to hold in position.

Current Models: Current models use a new control

assembly, identifi ed by three alignment holes (close

to throttle lever pivot). Based upon intended high-

speed (RPM) setting, throttle cable adjustment must

be made by matching hole in control lever with

correct alignment hole. Use appropriate hole for

corresponding high-speed settings. Move throttle

lever to align hole in lever with correct hole in control

bracket. Insert a pencil or a 6.35 mm (1/4 in.) drill bit

to hold in position.

4. Pull on outer shield of throttle control cable to

remove any slack. Tighten cable clamp securely.

Speed Control Bracket Alignment Hole Details

B

E

A

C

F G

A

H I

J

D

A

A Cable Clamp B Early Models

C Later Models D Current Models

E Alignment Hole F

Alignment Hole for

3000 RPM and

Higher

G

Alignment Hole for

Less Than 3000 RPM

H

Alignment Hole for

3101-3750 RPM

I

Alignment Hole for

2901-3100 RPM

J

Alignment Hole for

2400-2900 RPM