35

Electrical System

20 690 01 Rev. F KohlerEngines.com

SPARK PLUGS

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine is running.

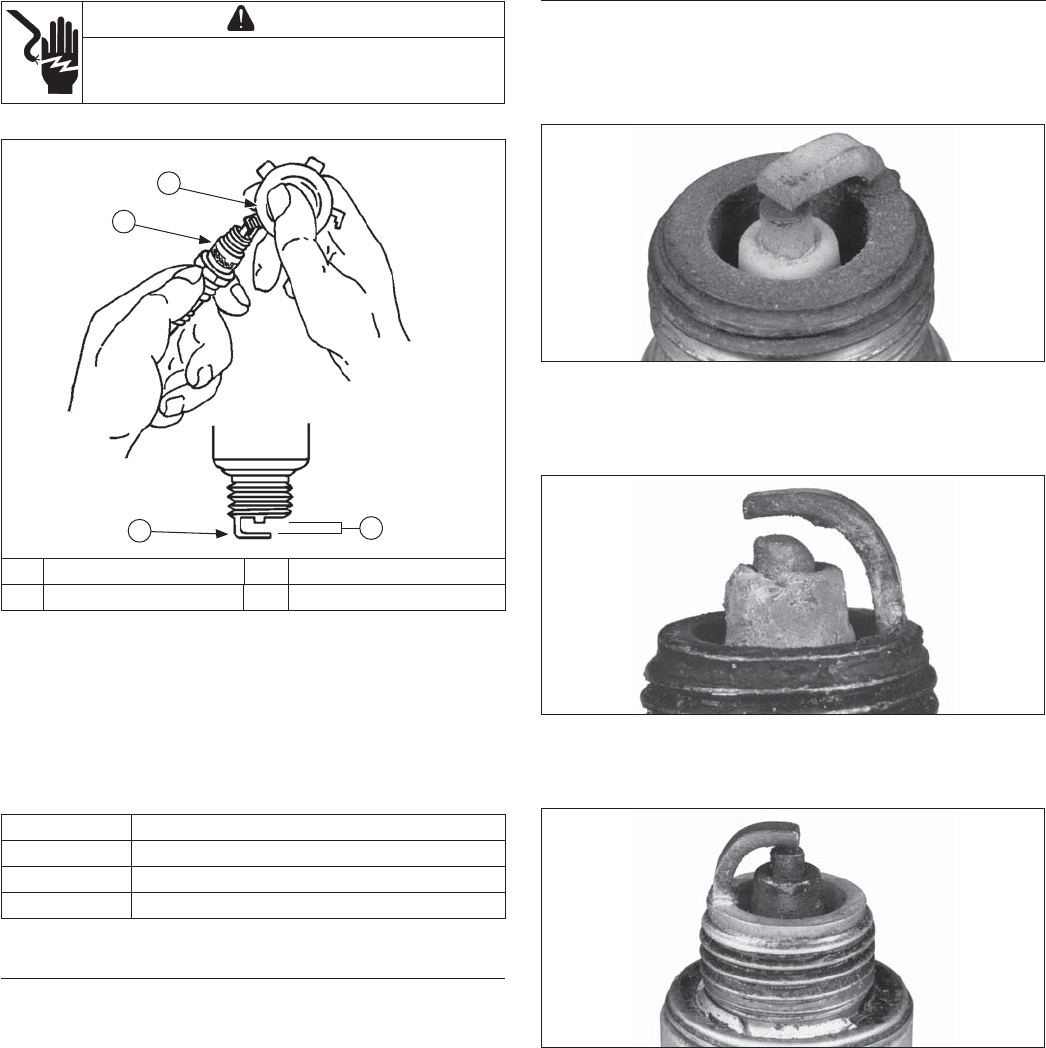

Spark Plug Component and Details

B

A

C

D

A Wire Gauge B Spark Plug

C Ground Electrode D Gap

NOTE: Do not clean spark plug in a machine using

abrasive grit. Some grit could remain in spark

plug and enter engine causing extensive wear

and damage.

Engine misfi re or starting problems are often caused

by a spark plug that has improper gap or is in poor

condition.

Engine is equipped with following spark plugs:

Gap 0.76 mm (0.03 in.)

Thread Size 14 mm

Reach 19.1 mm (3/4 in.)

Hex Size 15.9 mm (5/8 in.)

Refer to Maintenance for Repairs/Service Parts.

Service

Clean out spark plug recess. Remove plug and replace.

1. Check gap using wire feeler gauge. Adjust gap to

0.76 mm (0.03 in.).

2. Install plug into cylinder head.

3. Torque plug to 27 N·m (20 ft. lb.).

Inspection

Inspect each spark plug as it is removed from cylinder

head. Deposits on tip are an indication of general

condition of piston rings, valves, and carburetor.

Normal and fouled plugs are shown in following photos:

Normal

Plug taken from an engine operating under normal

conditions will have light tan or gray colored deposits. If

center electrode is not worn, plug can be set to proper

gap and reused.

Worn

On a worn plug, center electrode will be rounded and

gap will be greater than specifi ed gap. Replace a worn

spark plug immediately.

Wet Fouled

A wet plug is caused by excess fuel or oil in combustion

chamber. Excess fuel could be caused by a restricted air

cleaner, a carburetor problem, or operating engine with

too much choke. Oil in combustion chamber is usually

caused by a restricted air cleaner, a breather problem,

worn piston rings, or valve guides.