57

Disassembly/Inspection and Service

20 690 01 Rev. F KohlerEngines.com

1. Remove thrust washer(s) and cam gears from cam

shafts. Later models will have a thrust washer on

exhaust side only.

2. Remove screws securing cam levers to crankcase.

Mark cam levers for proper reassembly.

3. Pull exhaust side cam shaft and slotted thrust

washer, out of crankcase.

4. If engine contains an internal drain back tube,

unhook it from oil pump and pull it out of crankcase

passage. Check for cracks, brittleness or damage.

Replace if questionable in any way.

5. Remove screws securing oil pump and intake side

cam shaft to crankcase. If a drain back tube is used,

it may be unhooked and removed separately or

together with oil pump. Carefully pull upward on cam

shaft to remove assembly from crankcase cavity. A

small rubber oil pump outlet seal on outlet of oil

pump may become dislodged during removal. Do

not lose it.

6. If necessary, oil pump can be separated from intake

side cam shaft. Provide appropriate support for

shaft, and drive out lower pin. Oil pump assembly

can then be removed from cam shaft.

Oil Pump Assembly and Pressure Relief Valve

Inspection and Service

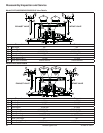

Outlet Seal Styles (Some Models)

BA

A Open Seal B Closed Seal

Pump Outlet Styles

A

B

A Open Outlet Seal B Closed Outlet Seal

Closure plate must be removed to inspect and service

oil pump. Check oil pump and gears for cracks, damage,

wear, and smooth rotation. Replace pump if any binding

is noted or reuse is questionable in any way.

A pressure relief valve is built into oil pump to limit

maximum pressure. It is not serviceable. If a problem

exists with pressure relief valve, oil pump assembly

should be replaced.

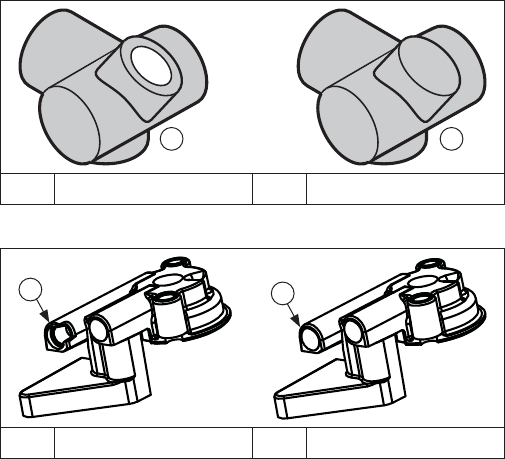

Automatic Compression Release (ACR)

These engines are equipped with an ACR mechanism.

ACR lowers compression at cranking speeds to make

starting easier.

Operation

ACR mechanism consists of an actuating spring and

a pivoting fl yweight/control pin assembly, located in

exhaust side cam gear. A thrust washer and mounting

closure plate hold ACR in position. At cranking speeds

(700 RPM or lower), spring holds fl yweight in and

rounded surface of control pin protrudes above exhaust

cam lobe. This pushes exhaust valve off its seat during

fi rst part of compression stroke. Compression is reduced

to an effective ratio of about 2:1 during cranking.

After starting, when engine speed exceeds 700 RPM,

centrifugal force overcomes force of the fl yweight spring.

Flyweight moves outward, rotating control pin to expose

the fl at surface, which is lower than cam lobe. Control

pin no longer has any effect on exhaust valve, and

engine operates at full power.

When engine is stopped, spring returns fl yweight/control

pin assembly to compression release position, ready for

next start.

Benefi ts

As a result of reduced compression at cranking speeds,

several important benefi ts are obtained:

1. Manual (retractable) starting is much easier. Without

ACR, manual starting would be virtually impossible.

2. Electric start models can use a smaller starter and

battery which are more practical for application.

3. ACR eliminates need for a spark retard/advance

mechanism. A spark retard/advance mechanism

would be required on engines without ACR to

prevent kickback which would occur during starting.

ACR eliminates this kickback, making manual

starting safer.

4. Choke control setting is less critical with ACR. If

fl ooding occurs, excess fuel is blown out opened

exhaust valve and does not hamper starting.

5. Engines with ACR start much faster in cold weather

than engines without ACR.

6. Engines with ACR can be started with spark plugs

which are worn or fouled. Engines without ACR are

more diffi cult to start with those same spark plugs.

Cam Gears Inspection and Service

Inspect gear teeth and cam lobes of intake and exhaust

cam gears. If lobes exhibit excessive wear, or teeth are

worn, chipped or broken, replacement of cam gear(s) will

be necessary.