69

Reassembly

20 690 01 Rev. F KohlerEngines.com

1. Check to make sure there are no nicks or burrs on

sealing surfaces of cylinder head or crankcase.

2. If engine uses a drain back check ball, install it into

keyhole slot in top of crankcase.

3. Install a new cylinder head gasket.

4. Install cylinder head and start six screws. Install thick

washer on screw closest to exhaust port.

5. Using torque sequence shown, torque cylinder head

screws in two stages; initially to 20.5 N·m

(180 in. lb.), and fi nally to 41.0 N·m (360 in. lb.).

Install Rocker Arms and Push Rods

NOTE: Installation and seating of push rods into cam

lever recesses during this sequence is critical.

Position engine with cylinder head up if possible,

to aid with proper installation of push rods and

rocker arms, and adjusting valve lash.

NOTE: If being reused, push rods should always be

installed in their original position.

1. Position push rod guide plates on cylinder head with

extruded edges down over push rod bores. Secure

by installing rocker arm pivot studs. Torque studs to

13.5 N·m (120 in. lb.).

2. Apply grease to contact surfaces of rocker arms and

adjusting nuts and install them onto pivot studs.

3. Note mark or tag identifying push rod as either

intake or exhaust. Apply grease to ends of push

rods. Insert push rods into push rod bores and seat

lower end into dimpled recess of cam levers. It may

be necessary to lift or shift lower end of push rod

slightly, and feel rod seats into recess. Once seated,

hold it in place as you position rocker arm. Push rod

must stay in recess while rocker arms are positioned

and adjusted.

4. With engine at TDC of compression stroke, insert

correct size fl at feeler gauge (see below) between

appropriate valve stem and rocker arm. Tighten

adjustment nut with a wrench until a slight drag is felt

on feeler gauge. Hold nut in position and torque set

screw (T15 Torx drive) to 5.5 N·m (50 in. lb.). To

prevent damage to nut, torque Torx screw only.

Perform adjustment procedure on other valve.

Clearance Specifi cations-Valve

Intake Valve 0.127 mm (0.005 in.)

Exhaust Valve 0.178 mm (0.007 in.)

Install Valve Cover

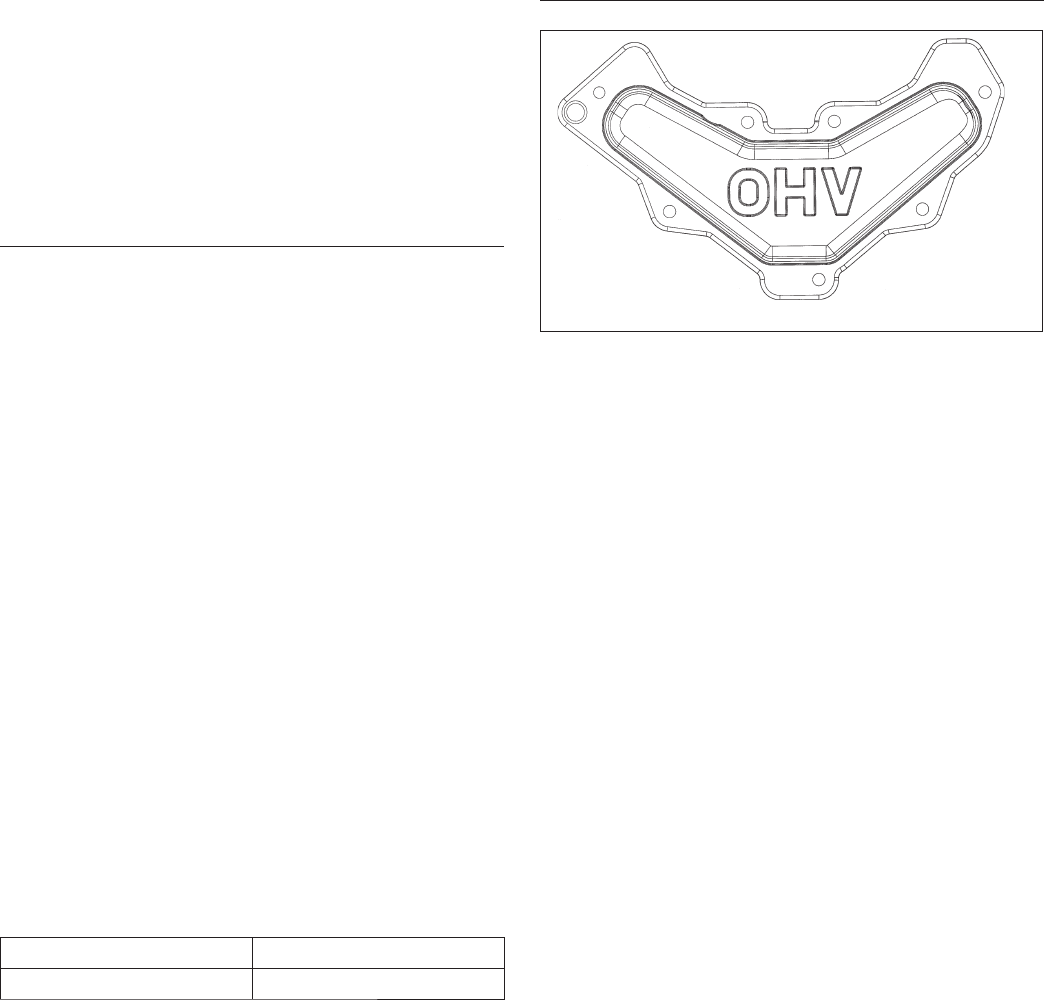

Valve Cover Torque Sequence

7

5

2

3

4

1

6

1. Make sure sealing surfaces of valve cover and

cylinder head are clean, and free of any nicks or

burrs.

2. Install a new valve cover gasket, followed by valve

cover. Position any brackets mounted on valve cover

and start seven mounting screws.

3. Torque valve cover screws to 11.0 N·m (95 in. lb.)

into new holes, or 7.5 N·m (65 in. lb.) into used

holes, using sequence shown.