29

Fuel System

20 690 01 Rev. F KohlerEngines.com

4. Loosen speed control bracket mounting screws.

Slide bracket forward or backward, until desired high

speed (RPM) is reached. Check speed with a

tachometer.

To increase high speed (RPM), move bracket toward

carburetor.

To decrease high speed (RPM), move bracket away

from carburetor.

5. Tighten speed control bracket mounting screws.

Recheck speed with a tachometer and readjust if

necessary.

Torque mounting screws as follows:

Into new hole – 11.0 N·m (95 in. lb.).

Into used hole – 7.5 N·m (65 in. lb.).

6. Adjust choke (see Choke Adjustment which follows).

Choke Adjustment

This procedure must follow High Speed Adjustment

just described. If not already completed, perform that

operation fi rst.

1. Turn choke adjusting screw out (counterclockwise),

until it no longer contacts choke lever.

2. Then turn it back in (clockwise), until it just makes

contact.

3. While observing choke link, move throttle control

lever to low idle (slow) position, then back to full

throttle (fast). Choke link should not move as throttle

moves through normal range. If it does, back

adjusting screw out until it no longer moves.

4. Move throttle control lever to choke position. Check

if choke has fully closed by placing your fi nger on

right side of lower end of choke lever/choke link and

applying gentle pressure towards carburetor. If

controls have been properly set, link should not

move.

SEPARATE THROTTLE AND CHOKE CONTROL

Some engines are equipped with separate throttle and

choke controls. This allows you to adjust choke and

throttle controls individually.

Install Separate Control Cables

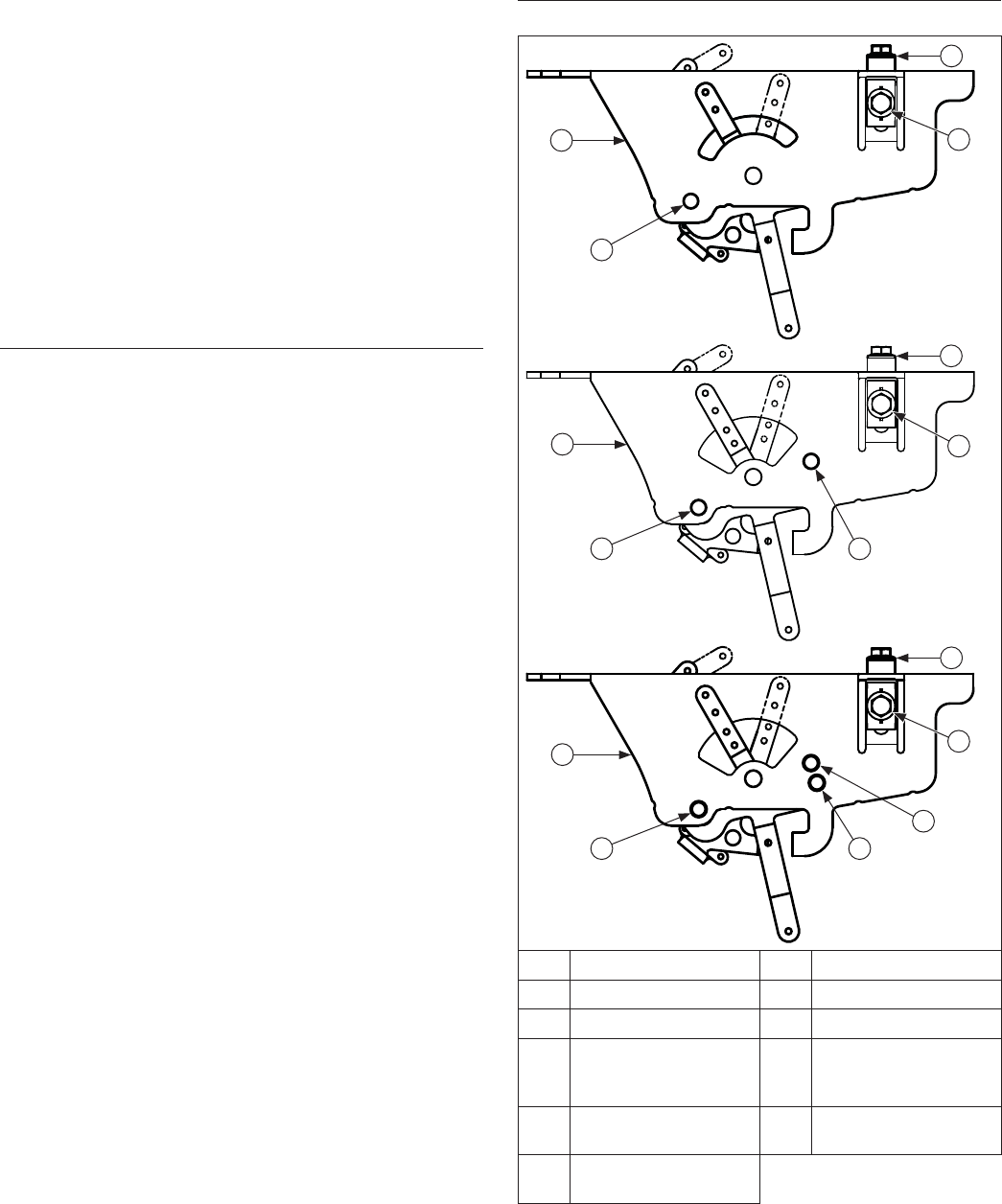

Speed Control Bracket Alignment Hole

B

F

A

C

D

G H

A

B

I J

K

E

A

B

A Throttle Cable Clamp B Choke Cable Clamp

C Early Models D Later Models

E Current Models F Alignment Hole

G

Alignment Hole for

3000 RPM and

Higher

H

Alignment Hole for

Less Than 3000 RPM

I

Alignment Hole for

3101-3750 RPM

J

Alignment Hole for

2901-3100 RPM

K

Alignment Hole for

2400-2900 RPM