66

Reassembly

KohlerEngines.com 20 690 01 Rev. F

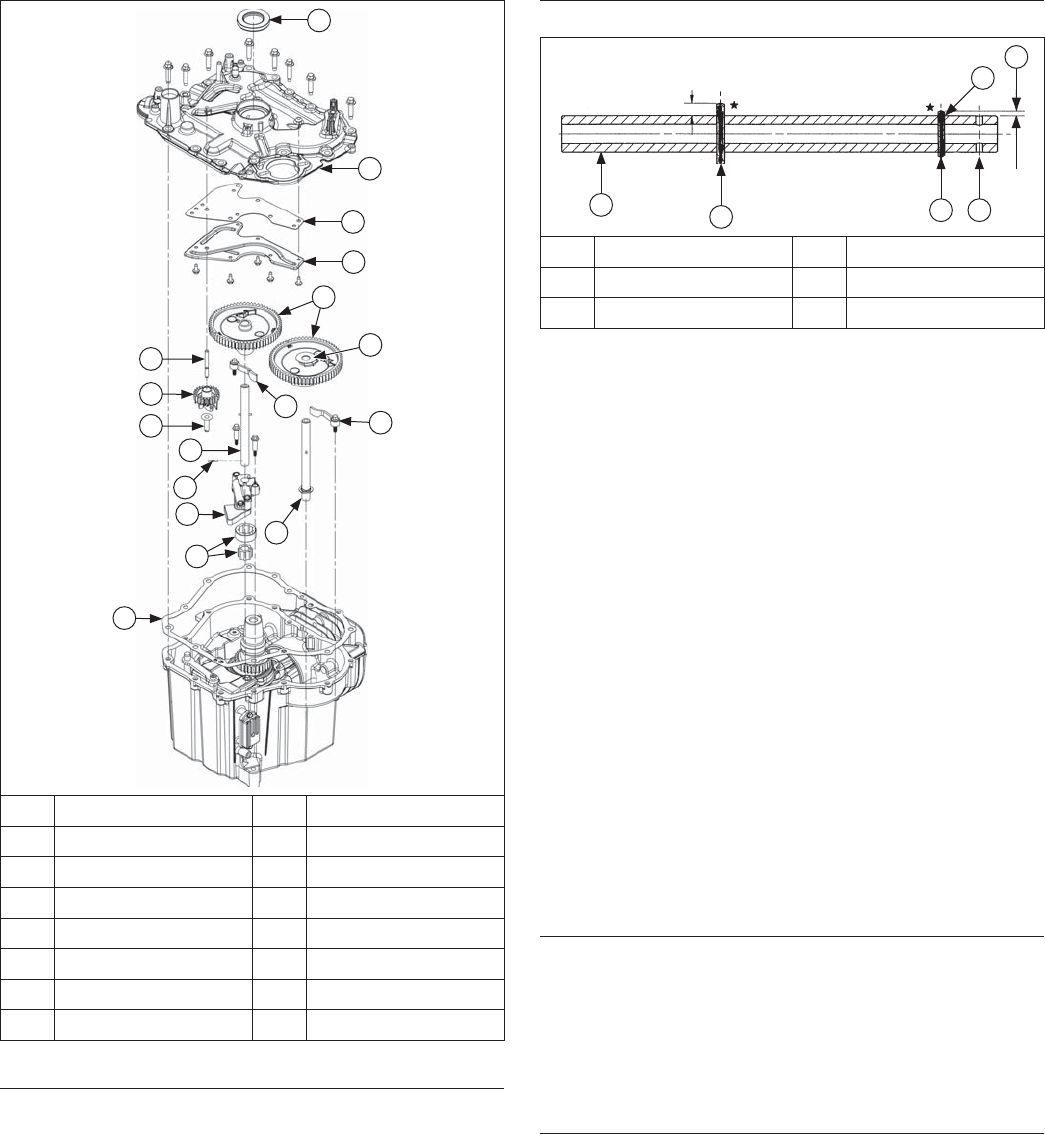

Cam/Closure Plate Components

G

F

H

L

G

O

N

K

J

I

M

P

B

C

D

E

A

A Oil Seal B Closure Plate

C Oil Passage Cover D Gasket

E Cam Gears F Thrust Washer

G Cam Levers H Cam Shaft (Exhaust)

I Closure Plate Gasket J Gerotor Gears

K Oil Pump L Cam Shaft Pin

M Cam Shaft (Intake) N Regulating Pin

O Governor Gear P Governor Gear Shaft

Install Cam Levers

Install two cam levers as shown. Dimple for seating push

rod must face up. Secure each cam lever using an M6

screw. Torque screws to 7.5 N·m (65 in. lb.). Lubricate

dimple and bottom side of cam lever with light grease or

oil.

Install Exhaust Cam Shaft and Cam Gear

Drive Pin Locations for Exhaust Cam Shaft

B

C

D

F

E

A

A Exhaust Cam Shaft B 3 mm Diameter Pin

C 2.5 mm Diameter Pin D 1.86 mm

E Hole Location 1 F Hole Location 2

1. If drive pins were removed from exhaust cam shaft,

follow same procedure used earlier for intake cam

shaft and reinstall them.

2. Apply a dab of grease to formed groove in thrust

washer. Slide washer onto cam shaft so short drive

pin is seated in groove. Grease will hold washer in

position. Pivot exhaust cam lever toward push rod

bore, then insert cam shaft into counterbore of

crankcase. Make sure pin stays in groove of thrust

washer.

3. Lubricate cam surfaces of cam gears with light

grease or oil.

4. Assemble and install ACR (automatic compression

release) into exhaust cam gear if removed for

servicing.

a. Install spring onto ACR weight with loop around

post, and formed upper leg hooked behind upper

section.

b. Install ACR assembly into hole of exhaust cam

gear and hook long leg behind notched tab.

5. Lift exhaust cam lever and install exhaust cam gear

with assembled ACR onto cam shaft, engaging slot

with upper drive pin. Rotate gear and shaft so EX

timing mark on cam gear is in 8 o’clock position.

Install thrust washer onto cam shaft.

Install Intake Cam on Cam Shaft

NOTE: Cam gear assemblies may contain either two or

four rivets.

Lift intake cam lever and install intake cam gear onto

intake cam shaft, engaging slot with upper drive pin.

Rotate gear and shaft so IN timing mark on cam gear

is in 4 o’clock position. Early models only: install thrust

washer (if used originally), onto cam shaft.

Install Crank Gear

Orient crankshaft so key is in 12 o’clock position. Hold

crank gear with timing marks visible and slide it onto

crankshaft and key, so timing marks on crank gear align

with timing marks on cam gears.