667 Size 80 and 100 Actuators

Instruction Manual

Form 1432

December 2007

9

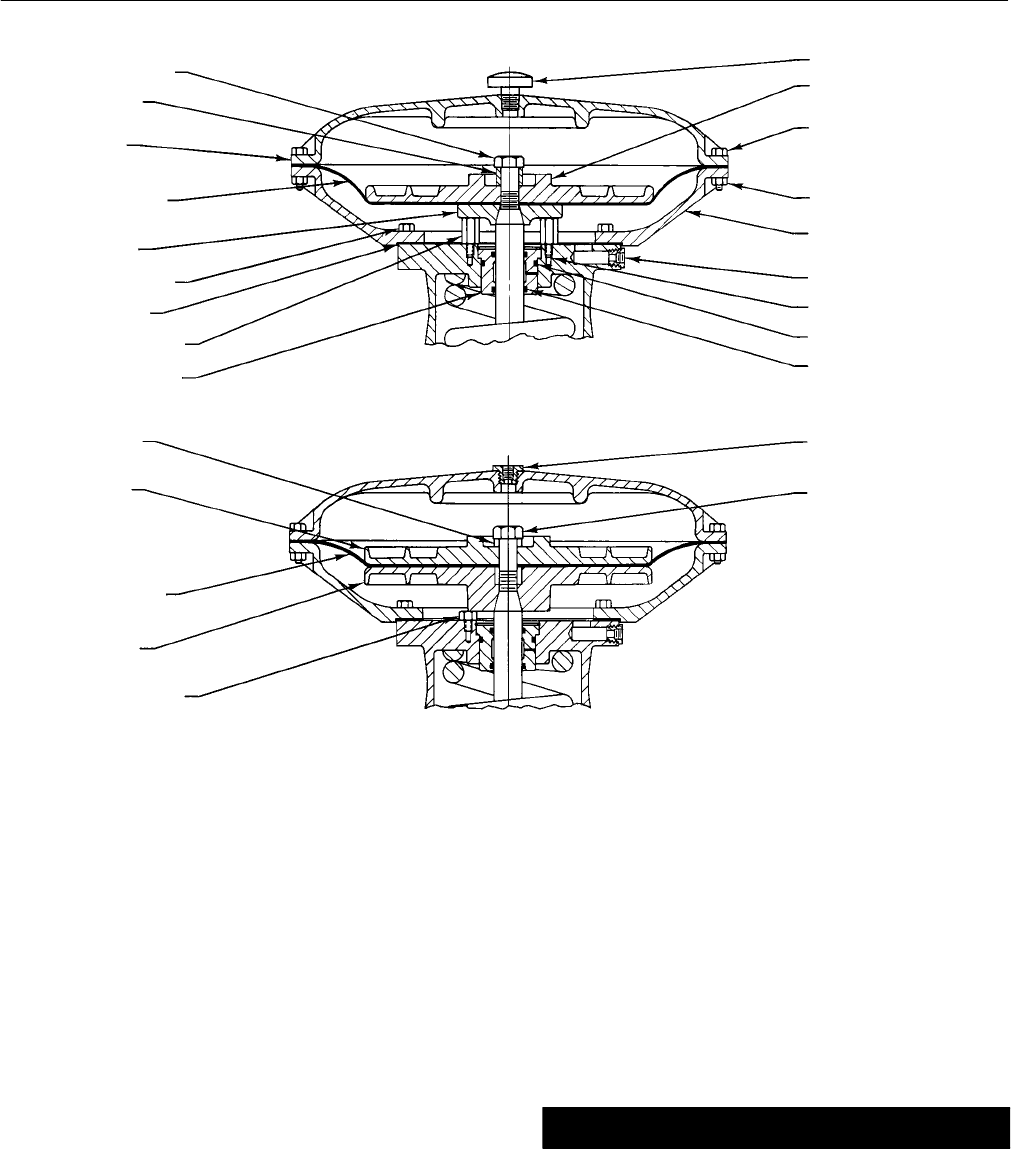

Figure 4. Size 80 Actuator Construction

CAP SCREW (KEY 12)

SPACER (KEY 2)

UPPER DIAPHRAGM

CASE (KEY 1)

DIAPHRAGM (KEY 3)

LOWER DIAPHRAGM

PLATE (KEY 71)

CAP SCREW (KEY 30)

GASKET (KEY 70)

TRAVEL STOP (KEY 84)

SEAL BUSHING (KEY 7)

VENT ASSEMBLY (KEY 17)

UPPER DIAPHRAGM

PLATE (KEY 4)

CAP SCREW (KEY 13)

HEX NUT (KEY 14)

LOWER DIAPHRAGM

CASE (KEY 64)

PIPE BUSHING (KEY 92)

SNAP RING (KEY 72)

O-RING (KEY 9)

O-RING (KEY 8)

SPACER (KEY 2)

UPPER DIAPHRAGM

PLATE (KEY 4)

DIAPHRAGM (KEY 3)

LOWER DIAPHRAGM

PLATE (KEY 71)

TRAVEL STOP (KEY 84)

PIPE BUSHING (KEY 78)

CAP SCREW (KEY 12)

STANDARD DIAPHRAGM CONSTRUCTION

TOP LOADED DIAPHRAGM CONSTRUCTION

50A8597-D

50A8599-C

C0772 / IL

(key 144), and secure using the cap screw (key 12).

Coat the cap screw threads with lithium grease

(key 237). Tighten the cap screw (key 12) to 544

NSm (400 lbfSft).

Note

Standard and top-loaded

constructions use the same key

numbers for parts. The parts look

different, but they use the same

assembly and disassembly sequence.

See figure 4, Size 80 Actuator

Construction.

10. Position the upper diaphragm casing (key 1) on

the diaphragm (key 3), and align the holes.

Note

When you replace actuator

diaphragms in the field, take care to

ensure the diaphragm casing cap

screws are tightened to the proper

load to prevent leakage, but do not

crush the material. Perform the

following tightening sequence with a

manual torque wrench for size 80 and

100 actuators.

CAUTION

Do not use lubricant on these cap

screws and nuts. Fasteners must be

clean and dry.

Overtightening the diaphragm casing

cap screws and nuts can damage the