Series 820 Instruction Manual Chapter 4 Maintenance & Repair

IM-82-C 4-11

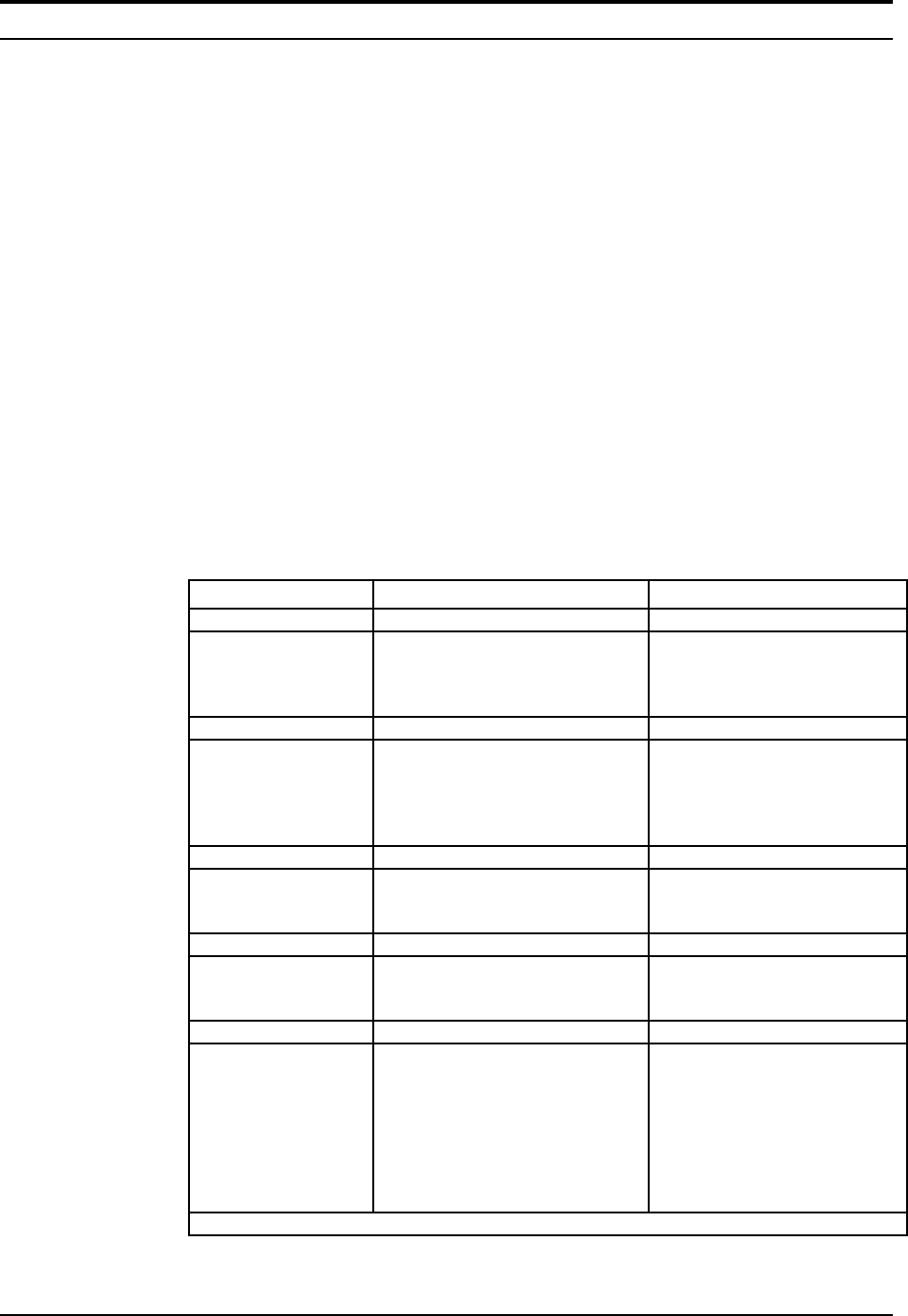

Transducer Troubleshooting

When you suspect that the transducer is not operating correctly,

there are a few simple checks that can be made before taking the unit

out of service:

1. Make certain that there are no leaks in the gas line.

2. Check that all cables are connected and are in good condition.

3. Verify that the power supply is in the correct range and

properly connected to the transducer.

4. Double check connector pin outs when replacing another manu-

facturer’s transducer.

This information is provided to help locate the cause of a transducer

failure. It is not intended to be an all inclusive repair guide. For most

repairs, the unit should be returned to the factory for service.

Problem Possible Cause Solution

No output No power

Inlet filter screen clogged

Clogged sensor

PCB defective

Plug in power supply

Clean or replace screen

Return to factory for cleaning*

Return to factory for repair

Unit will not zero Gas leak

Application requires high pres-

sure and non-horizontal mount-

ing

PCB defective

Find and correct leaks

Re-zero transducer

(see Chapter 3)

Return to factory for repair

Reads full scale

with no flow

Gas leak

Liquid present in system

Defective sensor

Find and correct leaks

Check for liquid in flow path

Return to factory for repair

Output too high Incorrect calibration or K-factor

Liquid present in system

Defective sensor

Correct calibration/k-factor

Check for liquid in flow path

Return to factory for repair

Out of calibra-

tion

Dirty or clogged sensor

Change in composition of gas

Gas leak

LFE dirty

Inlet filter screen clogged

Incorrect inlet conditions

(1/2-inch size models)

PCB defective

Return to factory for cleaning*

See K-factory tables

Find and correct leaks

Clean LFE

Clean or replace screen

Re-plumb transducer correctly

(See Chapter 2)

Return to factory for repair

*Model 822-S/824-S see sensor cleaning instructions