Series 820 Instruction Manual Chapter 4 Maintenance & Repair

IM-82-C 4-5

Flow Path Cleaning Model 822-S/824-S

Laminar Flow Element

The laminar flow element (LFE) is a precision flow divider which

diverts a preset amount of flow through the sensor tube. The LFE is

made of precision machined 316 stainless steel. The particular LFE

used depends on the gas and flow range of the instrument. Should

the LFE require cleaning or inspection due to deposition, use the ap-

propriate cleaning procedure which is specific to flow body size.

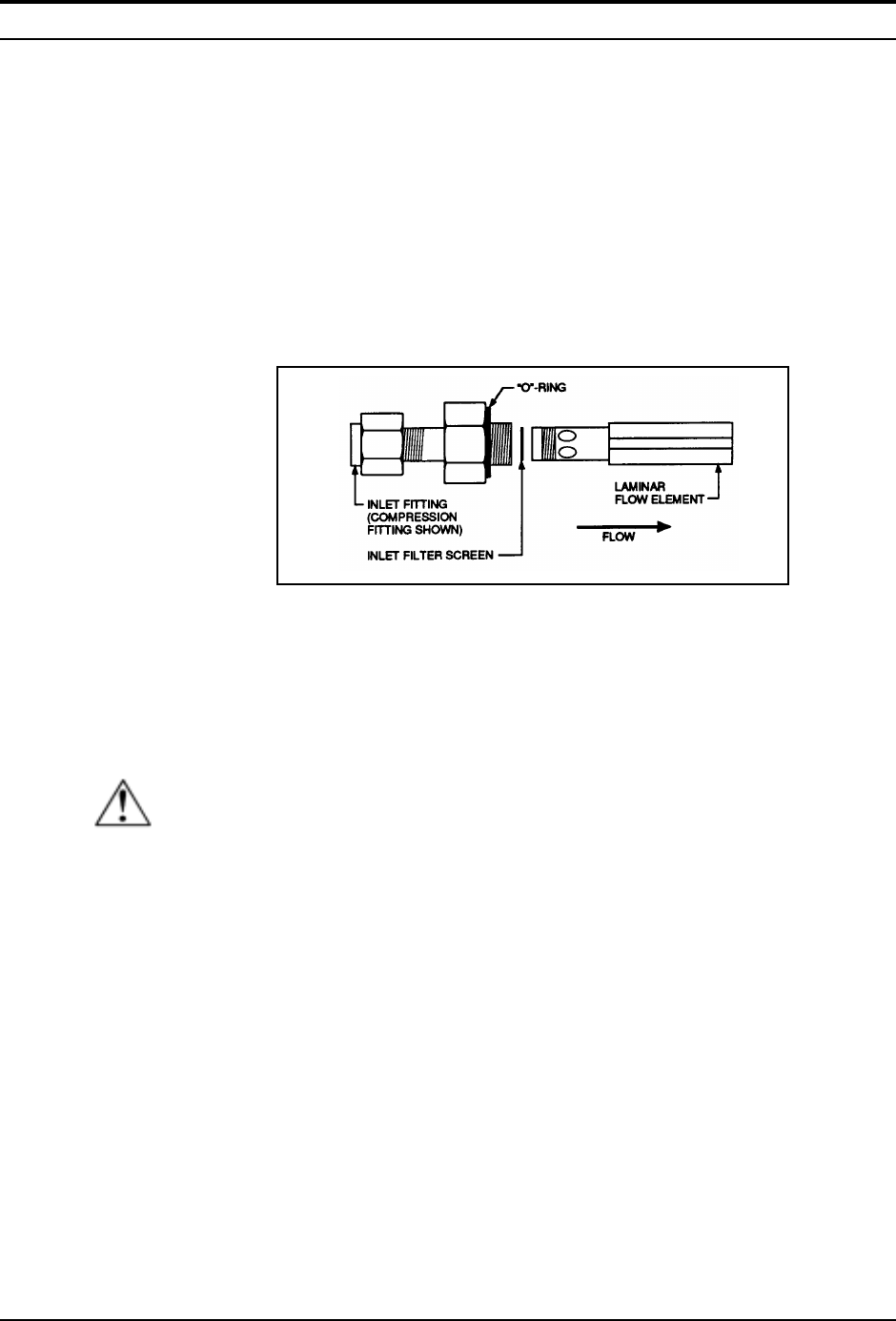

Figure 4-4. Low Flow Transducer LFE Cleaning

Low Flow Transducers:

The LFE is accessed by unscrewing the main inlet fitting and re-

moving it from the flow body. The LFE is screwed into the inlet fit-

ting, which has been specially machined for this purpose. To access

the components:

1. Remove the transducer from the system.

1. The inlet filter screen is held in place in the inlet fitting by the

LFE. Disassemble by holding the fitting steady with a wrench

and unscrewing the LFE with a medium flat-tipped screwdriver.

2. Remove the LFE assembly taking care not to bend the inlet

screen. Inspect the sealing O-ring and replace if necessary. In-

spect the inlet screen and replace if corroded or damaged. Light

to medium particulate contamination can be cleaned by back

washing with a suitable solvent. Air dry thoroughly.

3. Inspect the LFE for damage and replace if necessary. Replacement

of the LFE or inlet screen requires transducer re-calibration.

4. Re-assemble components. When the transducer is installed in the

system, leak test the connection. Re-zero the transducer (see

Chapter 3).

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.