Series 820 Instruction Manual Chapter 4 Maintenance & Repair

IM-82-C 4-3

Laminar Flow Element

The laminar flow element (LFE) is a precision flow divider which

diverts a preset amount of flow through the sensor tube. The LFE is

made of precision machined 316 stainless steel. The particular LFE

used depends on the gas and flow range of the instrument. To clean

or inspect the LFE:

1. Remove the transducer from the system.

1. Remove the inlet and outlet fittings. Pull out the LFE holddowns

and inlet/outlet screens.

2. The LFE has a slightly tapered shape with the larger diameter on

the upstream (inlet) side. To remove, use a blunt object which

does not mar the flow channels to push the LFE from the outlet

side to the inlet side. A 3/8-inch (9 mm) nut driver works well.

3. Clean the LFE using a suitable solvent. Make sure to carefully

clean all active flow channels in the LFE.

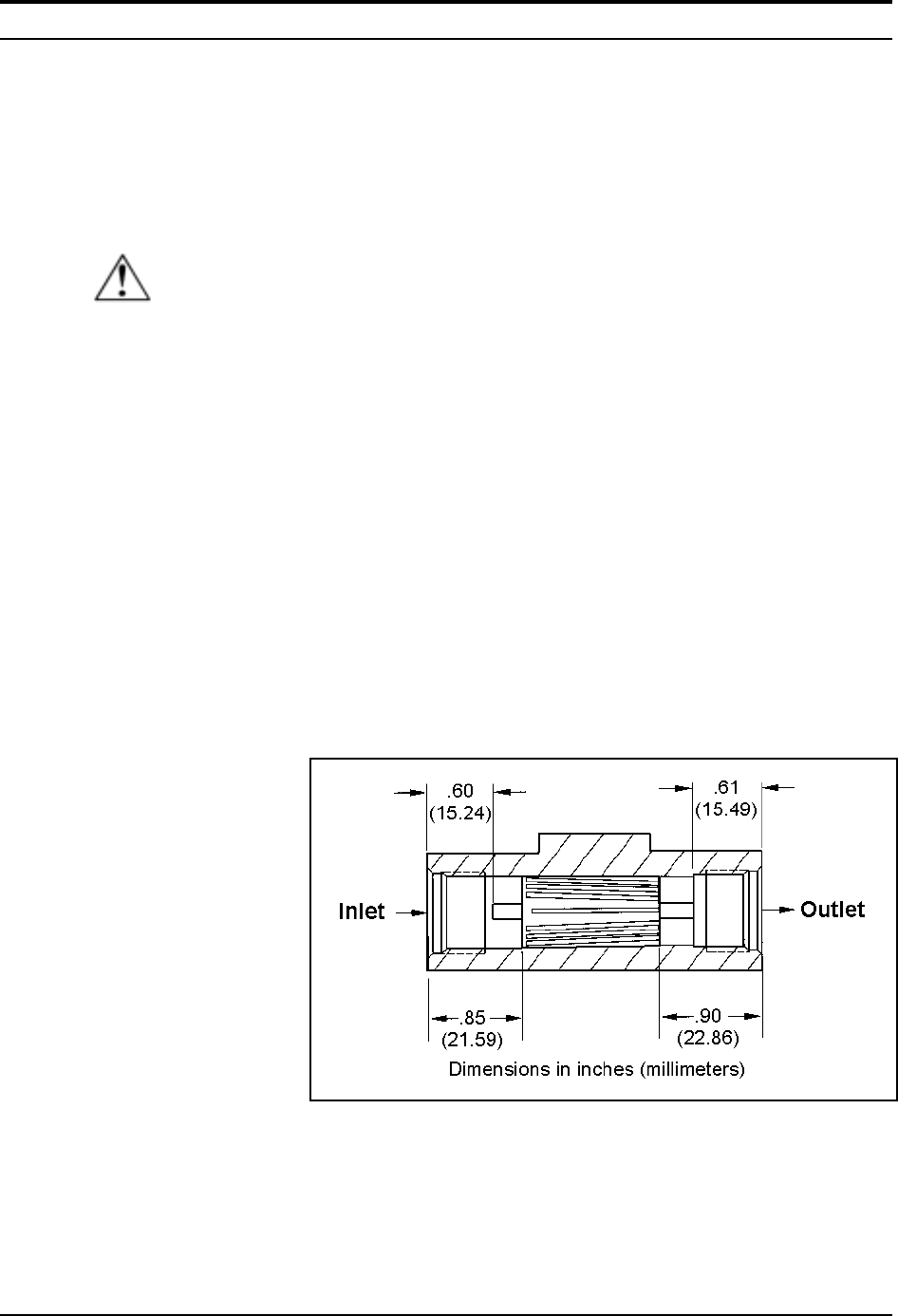

4. Re-install the LFE making sure to press it in the correct distance

as shown below.

5. Re-assemble remaining components. When the transducer is in-

stalled in the system, leak test the connection. Re-zero the trans-

ducer (see Chapter 3).

Figure 4-2. Correct LFE Position

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.