Chapter 2 Installation Series 820 Instruction Manual

2-2 IM-82-C

Installing the Transducer

Follow the installation instructions that apply to your transducer’s

process connection. For all 1/2-inch size process connections, observe

the piping recommendations given on page 2-3. Before operation, all

plumbing should be checked carefully for leaks and the transducer

purged with dry nitrogen.

Compression Fittings

1. Position the transducer with the flow direction arrow pointing

downstream in the direction of flow.

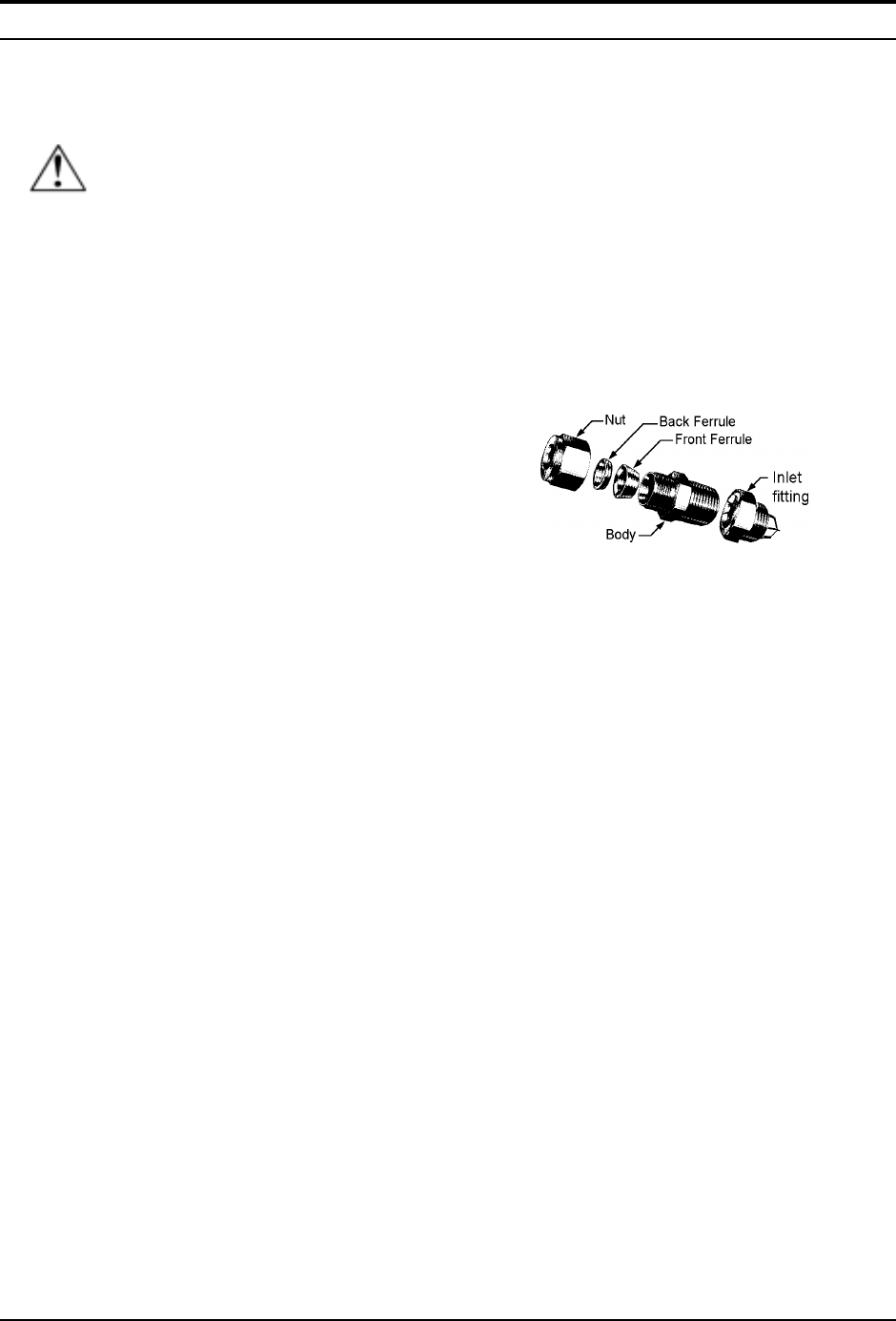

1. Verify the position of the front

and back ferrule. Insert the

tubing into the fitting. Make

sure that the tubing rests

firmly on the shoulder of the

fitting and that the nut is finger

tight. (Do not mix or inter-

change parts of tube fittings

made by different manufacturers.)

2. Hold the body steady with a backup wrench. For 1/2-

inch size, tighten the nut 1-1/4 turns from finger tight. For 1/8-

inch, 1/4-inch and 3⁄8-inch sizes, tighten only 3/4 turn from fin-

ger tight. Do not over-tighten!

3. Check the system’s entire flow path thoroughly for leaks. (Do

not use liquid leak detectors, instead monitor pressure decay.

Over-exposing the transducer to leak detector fluid may damage

the unit.)

VCO and VCR Fittings

1. Position the transducer with the flow direction arrow pointing

downstream in the direction of flow.

2. Install new o-rings compatible with the gas to be used. (Do not

mix or interchange parts of tube fittings made by different manu-

facturers.)

3. Hold the body steady with a backup wrench. Tighten

the nut finger tight and then 1/4 turn tighter with a wrench. Do

not over-tighten!

4. Check the system’s entire flow path thoroughly for leaks. (Do not

use liquid leak detectors, instead monitor pressure decay. Over-

exposing the transducer to leak detector fluid may damage the unit.)

Caution!

Only qualified

personnel should install

the transducer.