Chapter 4 Maintenance & Repair Series 820 Instruction Manual

4-6 IM-82-C

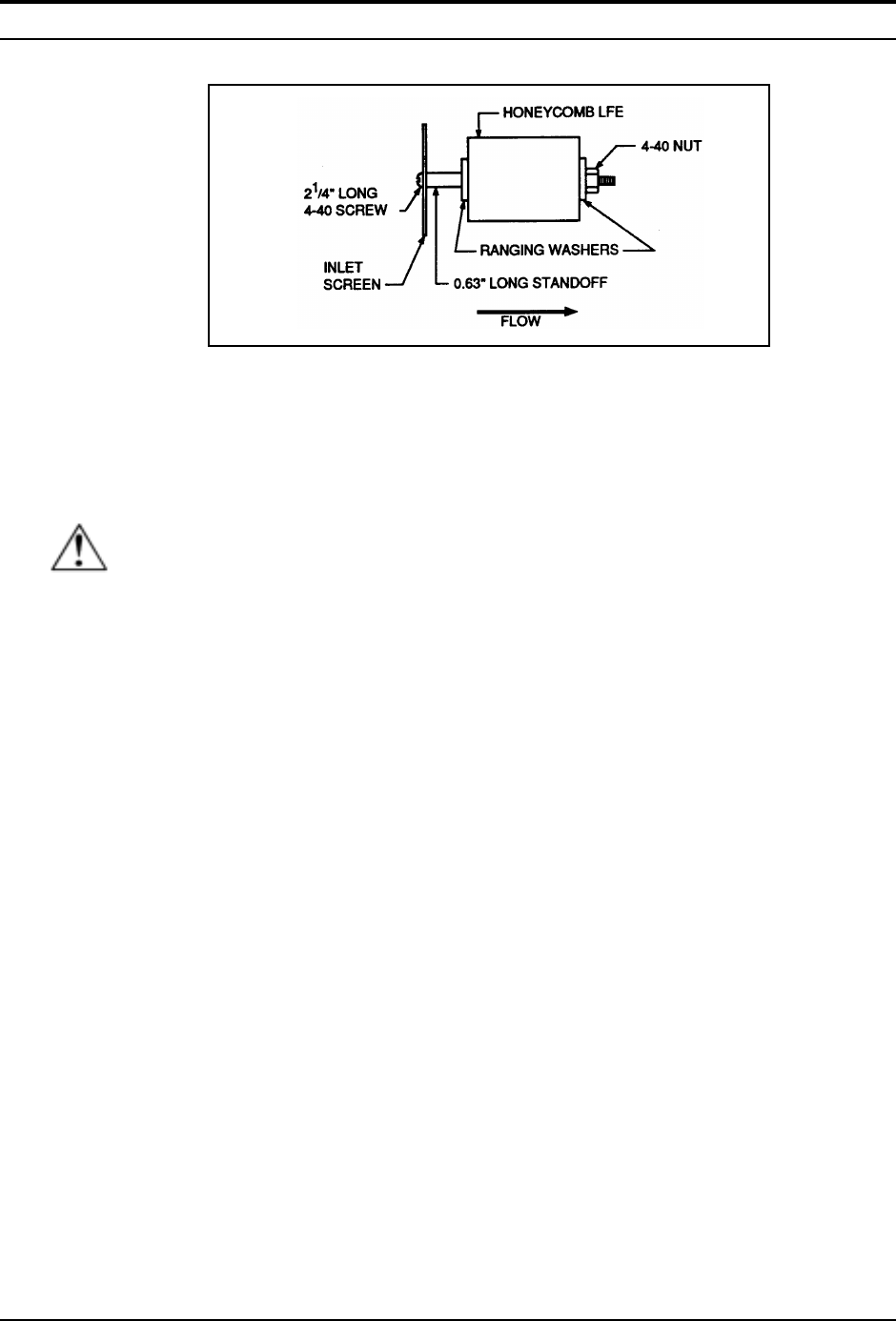

Figure 4-5. Medium Flow Transducer LFE Cleaning

Medium Flow Transducers:

In the medium flow body, the LFE assembly consists of the honey-

comb laminar flow element, inlet screen, 0.63 inch long standoff,

two ranging washers, 2-1⁄4 inch long 4-40 screw and 4-40 nut.

Range changes in the honeycomb element are made with various di-

ameter ranging washers. To access the components:

1. Remove the unit from the system.

2. Access the LFE by unscrewing the four 10-32 socket head cap

screws from the inlet side of the flow body and remove the inlet

end cap. (Note the position of the screws, one has a shorter

length.)

3. Remove the LFE assembly taking care not to bend the inlet

screen. Inspect the sealing O-ring and replace if necessary. In-

spect the inlet screen and replace if corroded or damaged. Light

to medium particulate contamination can be cleaned by back

washing with a suitable solvent. Air dry thoroughly.

4. Inspect the honeycomb element for damage and replace if neces-

sary. Replacement of the LFE or inlet screen requires transducer

re-calibration.

5. Re-assemble components. When the transducer is installed in the

system, leak test the connection.

6. To be within the original accuracy, calibrate the transducer (see

page 4-9).

Caution!

When using toxic or cor-

rosive gases, purge the

unit thoroughly with inert

dry gas before disconnect-

ing from the gas line.