ACT2000

3 INSTALLATION

The purpose of this section is to aid personnel in the installation, placement, and

environmental considerations to be observed for the ACT2000 and associated

equipment.

3.1 Inspection

The ACT2000 should be inspected immediately after unpacking. Check for

damage, paying particular attention to the external lead wires.

Note: Retain the actuator’s original shipping container. In the event of

future transportation requirements, this container will minimize

damage during shipment.

3.2 Environmental Considerations

The ACT2000 will operate satisfactorily with ambient air temperature of -40 °C

(-40 °F) to +93 °C (+200 °F). The ACT2000 is designed as an explosion-proof

assembly. The ACT2000 enclosure is Canadian Standards Association (CSA)

Type 3.

WARNING: Property Damage – Solvent/water may enter the electronics

area during a high-pressure wash.

3.3 Mechanical Installation

This section describes proper ACT2000 installation. Care should be exercised to

ensure compliance with the factory recommendations.

3.3.1 Space Requirements

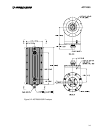

Figure 3-1 shows external dimensions and mounting provisions for the ACT2000-

590P. Figure 3-2 shows the external dimensions and mounting provisions for the

ACT2000-200F. The user should ensure additional swing clearance as required.

3.3.2 Mounting Considerations

The ACT2000 can be directly mounted to a gas turbine engine using brackets

provided by the engine manufacturer. The ACT2000 can be mounted in any

orientation (UP, DOWN, SIDEWAYS).

The ACT2000 may provide a clevis, or other method, for installing the motor end.

High strength bolts (0.375 diameter) are recommended to secure the actuator to

a user-provided mount bracket.

WARNING:

Lifting Hazard – Do not attempt to hand lift actuator. Use appropriate lifting

equipment.

3-1