99

Appendix A

Mounting the Transducer

To avoid drilling a hole to mount a thru-hull transducer, a transom mount transducer may be used

with epoxy inside a boat (“shoot-thru-hull” installation). For a transducer to be mounted inside the hull

(shoot-thru, not thru-hull), the boat must be fiberglass, no core (contact your boat manufacturer if you

are unsure). Test by placing a small amount of water inside the hull, placing the transducer on top of the

water, then verifying the accuracy of the locators versus the current water depth. If they are the same, use

slow-curing epoxy (non-silicone based) to affix the transducer to the inside of the hull.

Shoot-Thru-Hull Installation

The transducer is designed to be mounted inside a fiberglass hull. The standard plastic transom

mount transducer can also be mounted in this fashion using this method. If using a temperature sensing

transducer, the temperature displayed reflects the hull temperature.

Selecting a location:

1. The location has to be solid fiberglass, devoid of any air bubbles, laminates, fillers, or dead air space.

The location needs to be in an area of clean water at all speeds. Do not place the transducer over any

strakes or behind any obstruction on the hull that would create turbulence at speed.

NOTE: Many modern hulls have a prelocated pocket for shoot-thru-hull transducer

installation. If you are unsure if your hull is equipped with a pre-located pocket,

contact your hull manufacturer.

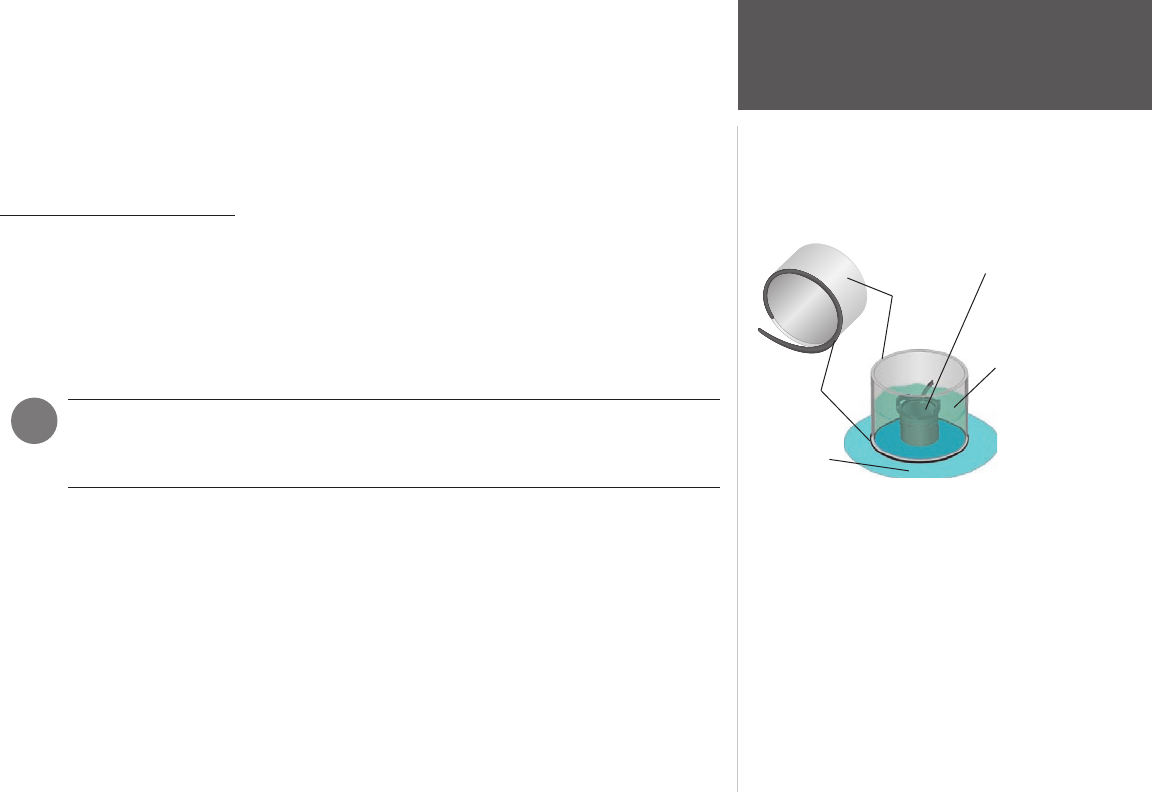

Testing the location:

1. Place the transducer in the water, pointed directly at the bottom and set unit for optimum perfor-

mance. Place the transducer in the test device as show on the side bar. If the sonar performance is

significantly degraded, another location needs to be tested.

Installing the transducer:

1. Lightly sand the surface of the hull and face of the transducer with 400 grit wet or dry sandpaper.

2. Build a dam using strip caulk about 1/4” tall. Pour about 1/8” of two part, slow cure epoxy in the

dam. Place the transducer in the epoxy, turning the transducer to work out any air bubbles.

3. Weight the transducer in place and allow to cure for 24 hours.

F

Testing the Location

Strip Caulk

or RTV Sealer

Hull Surface

PVC Pipe

or a Can

Weight transducer

to hold it in place

Fill Pipe or Can

with water or a

light mineral oil