26-SI ALTERNATOR

1G/287 4/96

PAGE

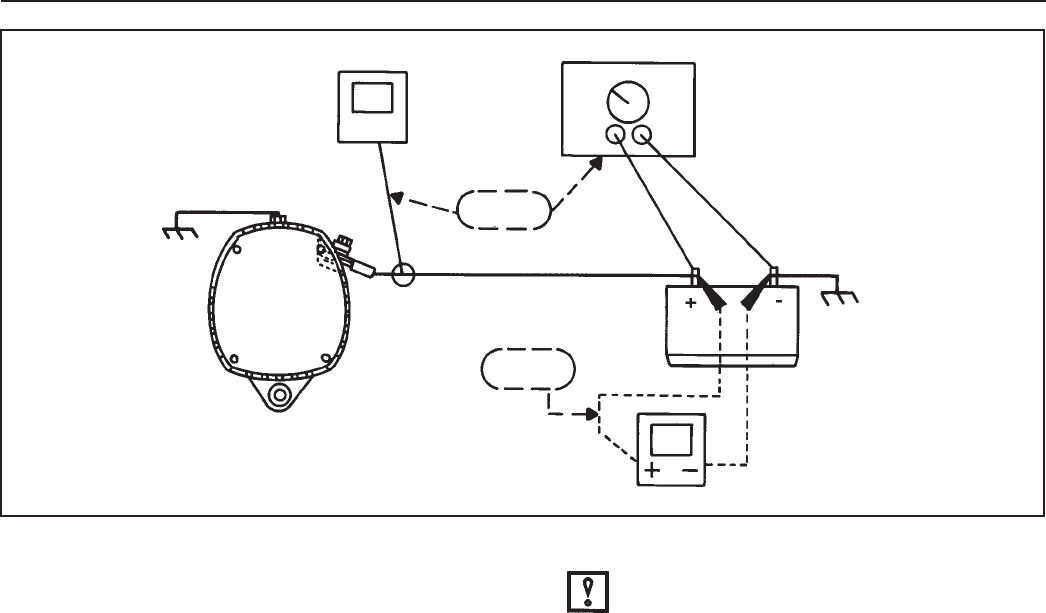

ALTERNATOR BENCH TEST

TEST EQUIPMENT NEEDED:

• Alternator Test Stand (5000 rpm capability at least

5 HP)

• Battery or Battery Set (fully charged)

• Variable Carbon Pile Load Test

• Ammeter (current capability at least 15 amps higher

than alternator rating)

• Voltmeter

• Ohmmeter

The bench test procedure will verify alternator

performance prior to installation on the vehicle. This test

checks the alternator output in the same manner as the

Rated Output Check covered earlier. If bench test

equipment is not available, install the alternator on the

engine according to manufacturer’s instructions and repeat

the Rated Output Check to verify alternator operation. If

bench test equipment is available, proceed as follows:

1. Mount alternator in test stand according to test stand

manufacturer’s instructions.

2. IMPORTANT: Battery or battery set must be

fully charged for test results to be valid.

NOTICE: When a 12-volt carbon pile load test is used

to diagnose a 24-volt system, attach load test only to 12-

volt potential in battery set. Attaching a 12-volt load

test to a 24-volt potential will damage the carbon pile.

With carbon pile load turned off and with battery or

battery set fully charged, make electrical connections

as shown in Fig. 47. Battery voltage and ground

polarity must be same as system in which alternator is

used. Check and record battery or battery set voltage

before proceeding with test.

3. With carbon pile load “off,” start test stand and slowly

increase alternator speed to highest rpm shown under

Cold Output specifications in 26-SI Alternator

Specifications at the end of this manual. Observe

voltmeter.

- If voltage does not increase but remains at or below

previous reading (Step 2), there is no alternator output.

Turn carbon pile load off and stop test stand. Residual

magnetism in rotor may have been lost. Skip to Step 5.

23

Figure 47. Alternator Bench Test

CLAMP-ON

AMMETER

CARBON PILE

E9

ALTERNATOR

E6,E8

V

BATTERY

VOLTMETER

26-5046