42

Checking the Hydraulic Lines

and Hoses

Daily, check hydraulic lines and hoses for leaks, kinked

lines, loose mounting supports, wear, loose fittings, weather

deterioration and chemical deterioration. Make all

necessary repairs before operating.

Hydraulic fluid escaping under pressure can

penetrate skin and cause injury.

• Make sure all hydraulic fluid hoses and lines are

in good condition and all hydraulic connections

and fittings are tight before applying pressure to

the hydraulic system.

• Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic leaks.

• Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

• Get immediate medical help if fluid is injected

into skin.

Warning

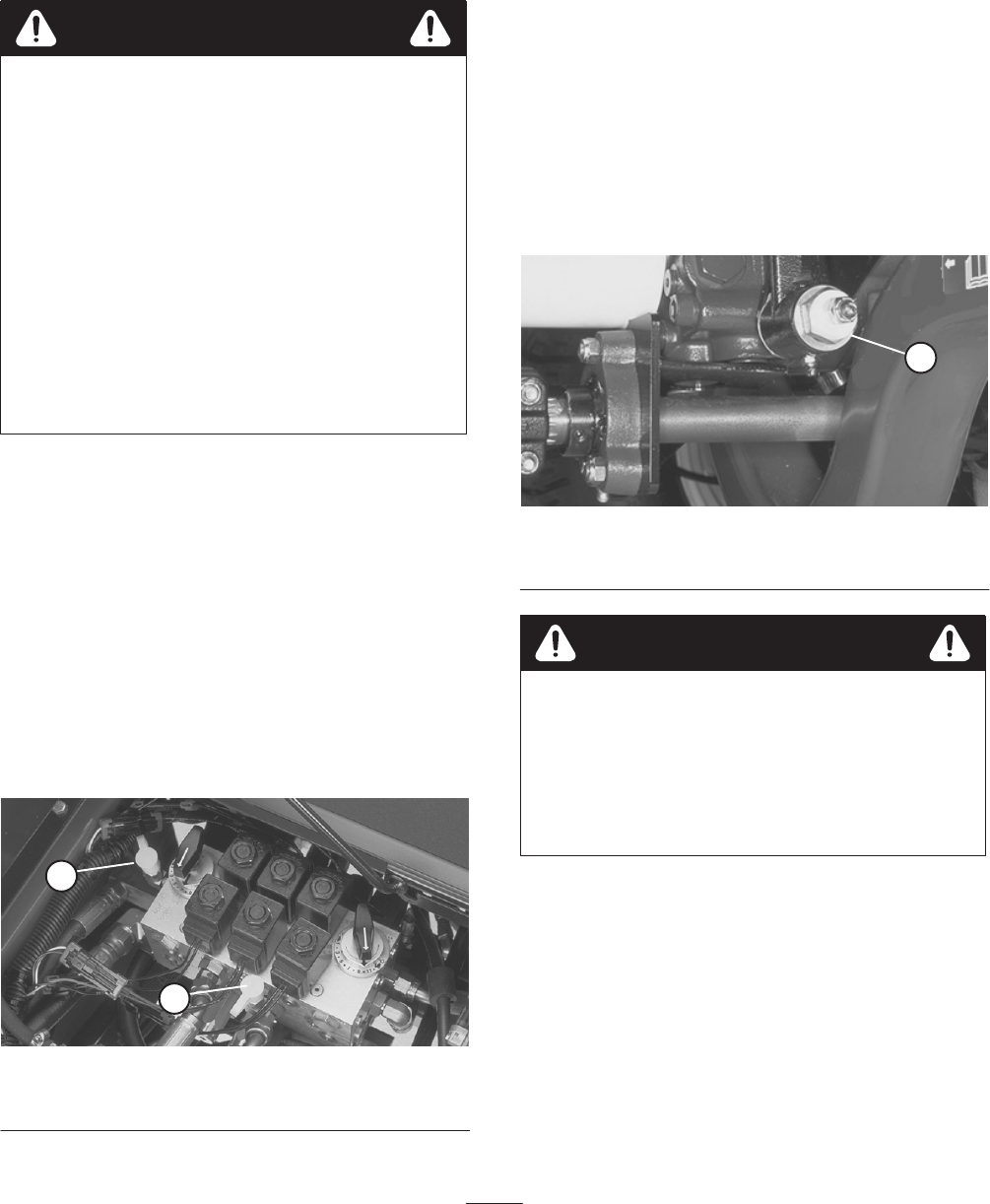

Hydraulic System Test Ports

The test ports are used to test pressure in the hydraulic

circuits. Contact your local Toro distributor for assistance.

Test Port #1 (Fig. 60) is used to assist in trouble shooting

the hydraulic circuit for the front cutting units and lift

cylinders.

Test Port #2 (Fig. 60) is used to assist in trouble shooting

the hydraulic circuit for the rear cutting units.

Test Port #3 (not shown) is located on the rear of the

hydrostatic transmission and is used to measure the charge

pressure of the transmission.

1

2

Figure 60

1. Test port #1 2. Test port #2

Adjusting the Traction Drive for

Neutral

The machine must not creep when traction pedal is

released. If it does creep, an adjustment is required.

1. Park machine on a level surface, shut engine off, and

lower cutting units to the floor. Depress only the right

brake pedal and engage the parking brake.

2. Jack up left side of machine until front tire is off the

shop floor. Support machine with jack stands to prevent

it from falling accidentally.

Note: On 4 wheel drive models, left rear tire must also be

off the shop floor or 4 wheel drive driveshaft must be

removed.

3. Under right side of machine, loosen locknut on traction

adjustment cam (Fig. 61).

1

Figure 61

1. Traction adjustment cam

The engine must be running so the final

adjustment of the traction adjustment cam can be

performed. This could cause personal injury.

Keep hands, feet, face, and other body parts away

from the muffler, other hot parts of the engine, and

any rotating parts.

Warning

4. Start engine and rotate cam hex in either direction until

wheel ceases rotation.

5. Tighten locknut securing adjustment.

6. Stop the engine and release the right brake. Remove

jack stands and lower the machine to the shop floor.

Test drive the machine to make sure it does not creep.