39

3. Loosen the hose clamps at both ends of the filter and

pull fuel lines off filter.

1

2

2

Figure 51

1. Fuel filter 2. Hose clamps

4. Slide hose clamps onto ends of fuel lines. Push fuel

lines onto fuel filter and secure them with hose clamps.

Be sure arrow on side of filter points toward the

injection pump.

Danger

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A fire

or explosion from fuel can burn you and others

and can cause property damage.

• Use a funnel and fill the fuel tank outdoors, in

an open area, when the engine is off and is cold.

Wipe up any fuel that spills.

• Do not fill the fuel tank completely full. Add fuel

to the fuel tank until the level is 1/4 to 1/2 in. (6

to 13 mm) below the bottom of the filler neck.

This empty space in the tank allows the fuel to

expand.

• Never smoke when handling fuel, and stay away

from an open flame or where fuel fumes may be

ignited by a spark.

• Store fuel in a clean, safety-approved container

and keep the cap in place.

Bleeding Air from the Injectors

Note: This procedure should be used only if fuel system

has been purged of air through normal priming procedures

and engine will not start; refer to Bleeding the Fuel System,

page 26.

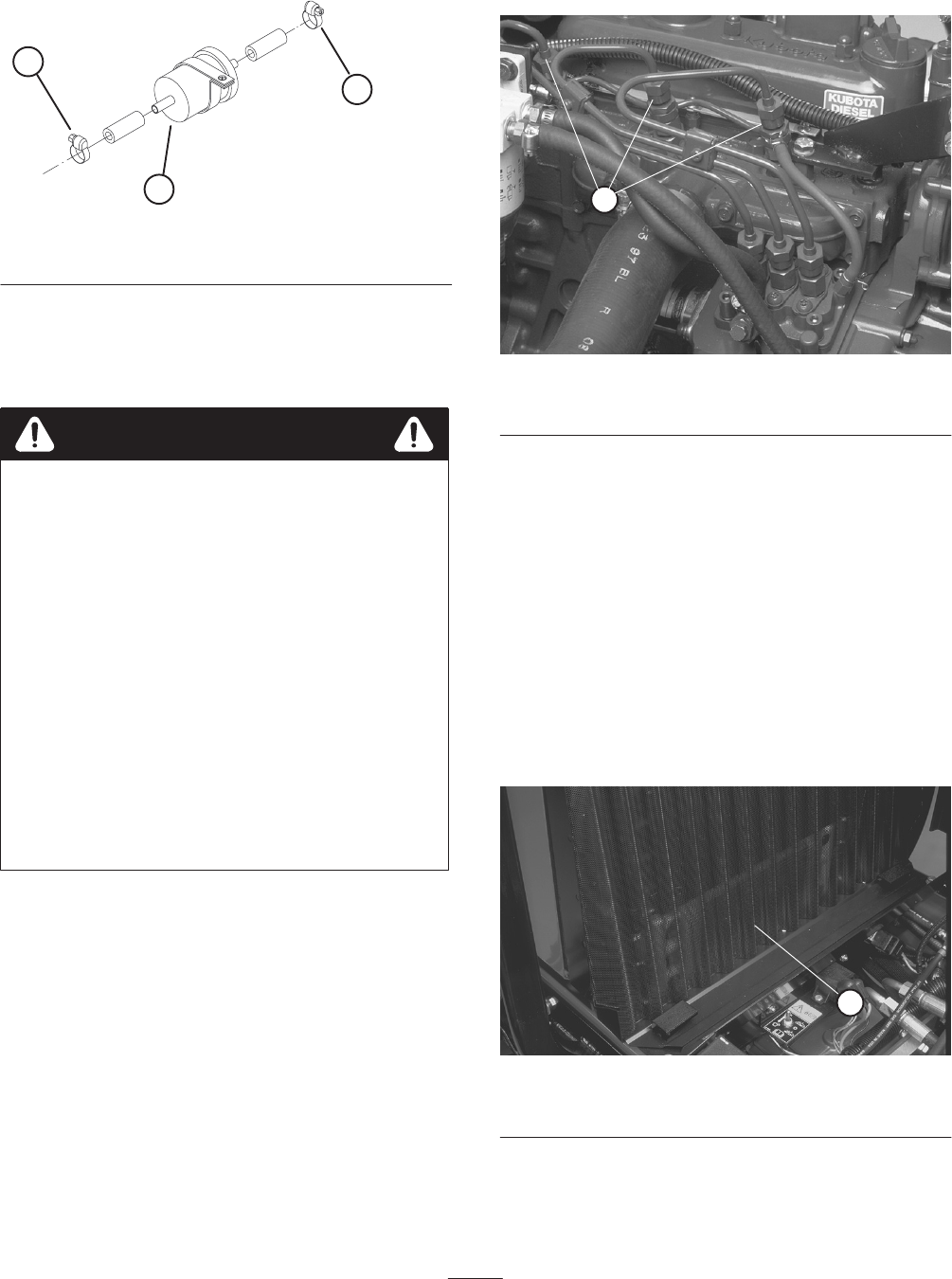

1. Loosen the pipe connection to the No. 1 nozzle and

holder assembly (Fig. 52).

2. Move throttle to FAST position.

3. Turn key in key switch to START position and watch

fuel flow around connector. Turn key to OFF position

when solid flow is observed.

4. Tighten pipe connector securely.

5. Repeat steps on remaining nozzles.

1

Figure 52

1. Fuel injectors (3)

Servicing the Engine Cooling

System

Removing Debris

Remove debris from screen, oil coolers and radiator daily,

clean more frequently in dirty conditions.

1. Turn engine off and raise hood. Clean engine area

thoroughly of all debris.

2. Loosen clamps and pull up on screen to slide it out of

mounting tracks (Fig. 53). Clean screen thoroughly with

compressed air.

1

Figure 53

1. Screen