22

Checking the Hydraulic Fluid

The machines reservoir is filled at the factory with

approximately 8 gallons of high quality hydraulic fluid.

Check the level of the hydraulic fluid before the engine

is first started and daily thereafter. The recommended

replacement fluid is:

Toro Premium Transmission/Hydraulic Tractor

Fluid

(Available in 5 gallon pails or 55 gallon drums. See

parts catalog or Toro distributor for part numbers.)

Alternate fluids: If the Toro fluid is not available, other

petroleum–based Universal Tractor Hydraulic Fluids

(UTHF) may be used provided its specifications fall within

the listed range for all the following material properties and

it meets industry standards. We do not recommend the use

of synthetic fluid. Consult with your lubricant distributor to

identify a satisfactory product

Note: Toro will not assume responsibility for damage

caused by improper substitutions, so use only products

from reputable manufacturers who will stand behind their

recommendation.

Material Properties:

Viscosity, ASTM D445 cSt @ 40_ C 55 to 62

cSt @ 100_ C 9.1 to 9.8

Viscosity Index ASTM D2270 140 – 152

Pour Point, ASTM D97 –35_ F to –46_ F

Industry Specifications:

API GL–4, AGCO Powerfluid 821 XL, Ford New

Holland FNHA–2–C–201.00, Kubota UDT, John Deere

J20C, Vickers 35VQ25 and Volvo WB–101/BM.

Note: Many hydraulic fluids are almost colorless, making it

difficult to spot leaks. A red dye additive for the hydraulic

system oil is available in 2/3 oz. (20 ml) bottles. One bottle

is sufficient for 4–6 gal (15–22 1) of hydraulic oil. Order

part no. 44–2500 from your authorized Toro distributor.

1. Position machine on a level surface, lower the cutting

units and stop the engine.

2. Clean area around filler neck and cap of hydraulic tank

(Fig. 19). Remove cap from filler neck.

1

Figure 19

1. Hydraulic tank cap

3. Remove dipstick from filler neck and wipe it with a

clean rag. Insert dipstick into filler neck; then remove it

and check level of fluid. Fluid level should be within

1/4 inch of mark on dipstick.

4. If level is low, add appropriate fluid to raise level to full

mark.

5. Install dipstick and cap onto filler neck.

Checking the Rear Axle

Lubricant

Note: This procedure is for Model 03544 only.

The rear axle has three separate reservoirs which use SAE

80W-90 wt. gear lube. Although the axle is shipped with

lubricant from the factory, check the level before operating

the machine.

1. Position the machine on a level surface.

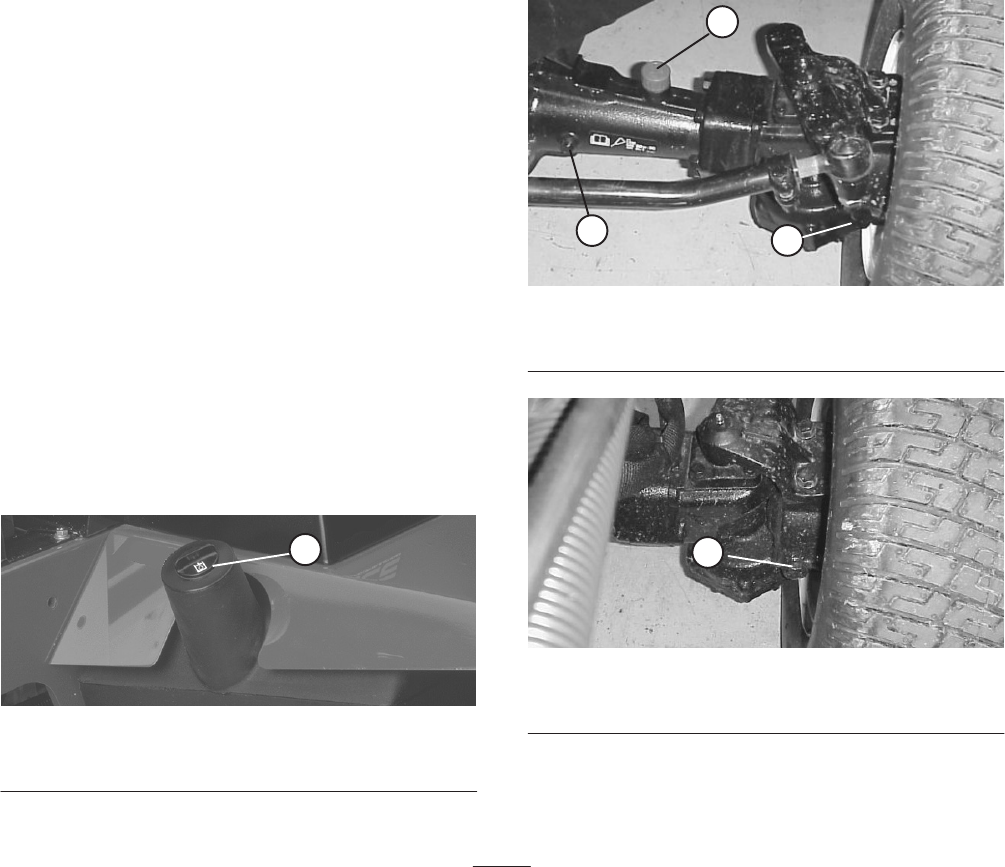

2. Remove the 3 check plugs from axle (Fig. 20 and 21)

and make sure lubricant is up to bottom of each hole.

1

1

2

Figure 20

1. Check plug 2. Fill plug

1

Figure 21

1. Left check plug (rear of axle)

3. If level is low, remove center fill plug and add enough

lubricant to bring the level up to the bottom of the

center check plug hole.