Manual: 152-082010 301-305-306_303-307 Series Page 27 of 35

4.4. End Cap Removal

The end cap on the inlet side must be removed to gain access to shunt assembly. First remove power

and shut off the supply of gas to the instrument. Disconnect the fittings on the inlet and outlet sides of

the transducer and remove it from the system plumbing. On both the HFM-301 and HFC-303, remove the

four Allen head screws holding the end cap to the instrument. Carefully remove the “O”-ring sealed end

cap and shunt, noting their order and the proper annular orientation of the shunt. The shunt position is

critical to the flow dynamics and can substantially affect the instrument linearity. The shunt can be

severely damaged if dropped. Examine the shunt. If damaged, dirty or blocked, clean and replace as

applicable. Reassemble in the reverse order of disassembly. Secure the endcap with 65 in lb. (7.3 N.m)

to 85 in lb (9.6 N-m) of torque on each high-tensile socket head cap screw. Use of a fastener other than

the one mentioned here may result in leakage at the seal. Recalibration of the 301/303 series

instrument is necessary.

For the HFM-305/307 remove the four 12 point bolts securing the endcap while carefully holding the

endcap in place. Carefully remove the metal gasket sealed endcap and shunt, noting their order and the

proper annular orientation of the shunt. The shunt position is critical to the flow dynamics and can

substantially affect the instrument linearity. The shunt can be severely damaged if dropped. Examine

the shunt. If damaged, dirty or blocked, clean and replace as applicable. Reassemble in the reverse

order of disassembly replacing the used metal gasket with a new one. Secure the endcap with 35 ft lb. (

47.5 N.m) to 40 ft lb. (54.3 N.m) of torque on each 12 pt bolt. Use of a fastener other than the one

mentioned here may result in leakage at the seal. Recalibration of the 305/307 series instrument is

necessary.

For the HFM-306, remove the six hex socket bolts from the inlet end cap. Remove the end cap and

ensure that the o-ring is not damaged. Remove the flow conditioning screen assembly and if damaged,

dirty or blocked, clean and replace as applicable. Carefully remove the flow straightener and shunt

assembly. If damaged, dirty or blocked, clean and replace as applicable. Reassemble in the reverse order

of disassembly. Recalibration of the HFM-306 instrument is necessary.

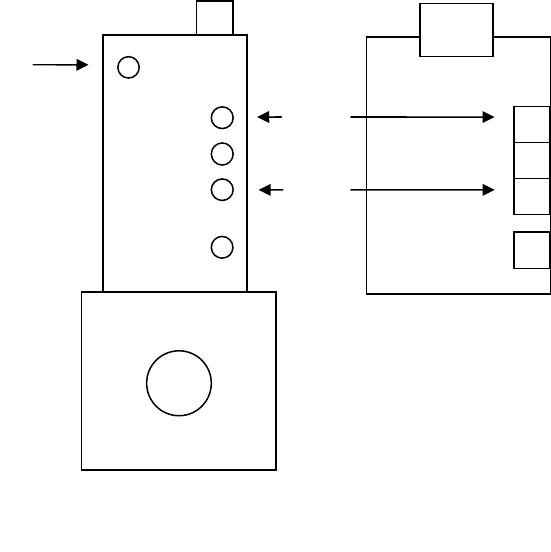

Figure 4-2

Zero

Span

Control

Loop Gain

PC

Board