Manual: 152-082010 301-305-306_303-307 Series Page 15 of 35

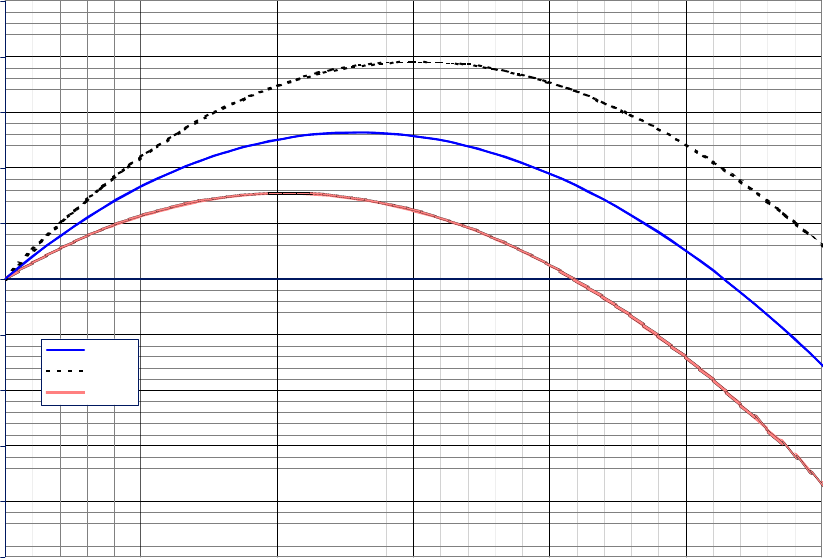

Span Error vs Pressure

-1.0%

-0.8%

-0.6%

-0.4%

-0.2%

0.0%

0.2%

0.4%

0.6%

0.8%

1.0%

0 50 100 150 200 250 300

Pressure(psig)

Span Error (% reading)

Mean error

max

min

Figure 2-7

2.7.4. Blending of Gases

In the blending of two gases, it is possible to maintain a fixed ratio of one gas to another. In this case,

the output of one flow controller is used as the reference voltage for the set point potentiometer of a

second flow controller. The set point potentiometer then provides a control signal that is proportional

to the output signal of the first flow controller, and hence controls the flow rate of the second gas as a

percentage of the flow rate of the first gas.

EXAMPLE: Flow controller A has 0 - 100 slm range with a 5.00 volt output at full scale. Flow

controller B has 0 - 10 slm range with a 5.00 volt output at full scale. If flow controller A is set at

80 slm, its output voltage would be 4.00 volts (80 slm/100 slm x 5.00 volts = 4.00 volts). If the

output signal from flow controller A is connected to the command potentiometer of flow controller

B, it then becomes a variable reference voltage for flow controller B proportional to the flow rate

of flow controller A.

If the set point potentiometer of flow controller B is set at 50% of full scale, and the reference

voltage from flow controller A is 4.00, then the command signal going to flow controller B would be

2.00 volts (4.00 volts x 50.0% = 2.00 volts). The flow of gas through flow controller B is then

controlled at 4 slm (2.00 volts/5.00 volts x 10 slm = 4 slm).

The ratio of the two gases is 20:1 (80 slm/4slm). The % mixture of gas A is 95.2 (80slm/84slm and

the % mixture of gas B is 4.8% (4 slm/84 slm).

Should the flow of flow controller A drop to 78 slm, flow controller B would drop to 3.9 slm, hence

maintaining the same ratio of the mixture. (78 slm/100slm x 5v = 3.90v x 50% = 1.95v; 1.95v/5.00v

x 10 slm = 3.9 slm; 78 slm: 3.9 slm = 20:1)