10.19

ELECTRICAL

10

9923142 - 2011 RANGER RZR / RZR S / RZR 4 Service Manual

© Copyright 2010 Polaris Sales Inc.

Fan Control Circuit Operation / Testing

Power is supplied to the fan via the Orange/Black wire when the

relay is ON. The ground path for the fan motor is through the

Brown harness wire. Refer to “RELAYS” later in this chapter

for more information on fan functions.

NOTE: The fan may not function or operation may

be delayed if coolant level is low or if air is trapped in

the cooling system. Be sure cooling system is full

and purged of air. Refer to Chapter 2 “Maintenance”

for cooling system information.

Fan Control Circuit Bypass Test

1. Disconnect harness from coolant temperature sensor on

the engine cylinder head (see Chapter 4 for location).

2. With the transmission in Park, start the engine. After a few

seconds, the fan should start running and the “Check

Engine” indicator should display on the instrument cluster.

This indicates all other components are working properly.

3. If the fan does not run or runs slowly, check the fan motor

wiring, ground, motor condition and mechanical relay for

proper operation. Repair or replace as necessary. If the fan

runs with the sensor harness disconnected, but will not turn

on when the engine is hot, check the coolant temperature

sensor and connector terminals.

Coolant Temperature Sensor

The coolant temperature sensor can be tested using an ohmmeter

or voltmeter.

1. With the engine and temperature sensor at room

temperature (68

F = 20C), disconnect the harness.

2. With the meter in the ohms mode, place the meter leads

onto the sensor contacts.

3. Use the table Temperature / Resistance table to determine

if the sensor needs to be replaced.

NOTE: If the coolant temperature sensor or circuit

malfunctions the radiator fan will default to 'ON'.

EFI DIAGNOSTICS

EFI Component Testing

All EFI component information and diagnostic testing

procedures are located in Chapter 4.

Refer to Chapter 4 “Electronic Fuel Injection System (EFI)”

when diagnosing an EFI system or component.

FUEL SENDER

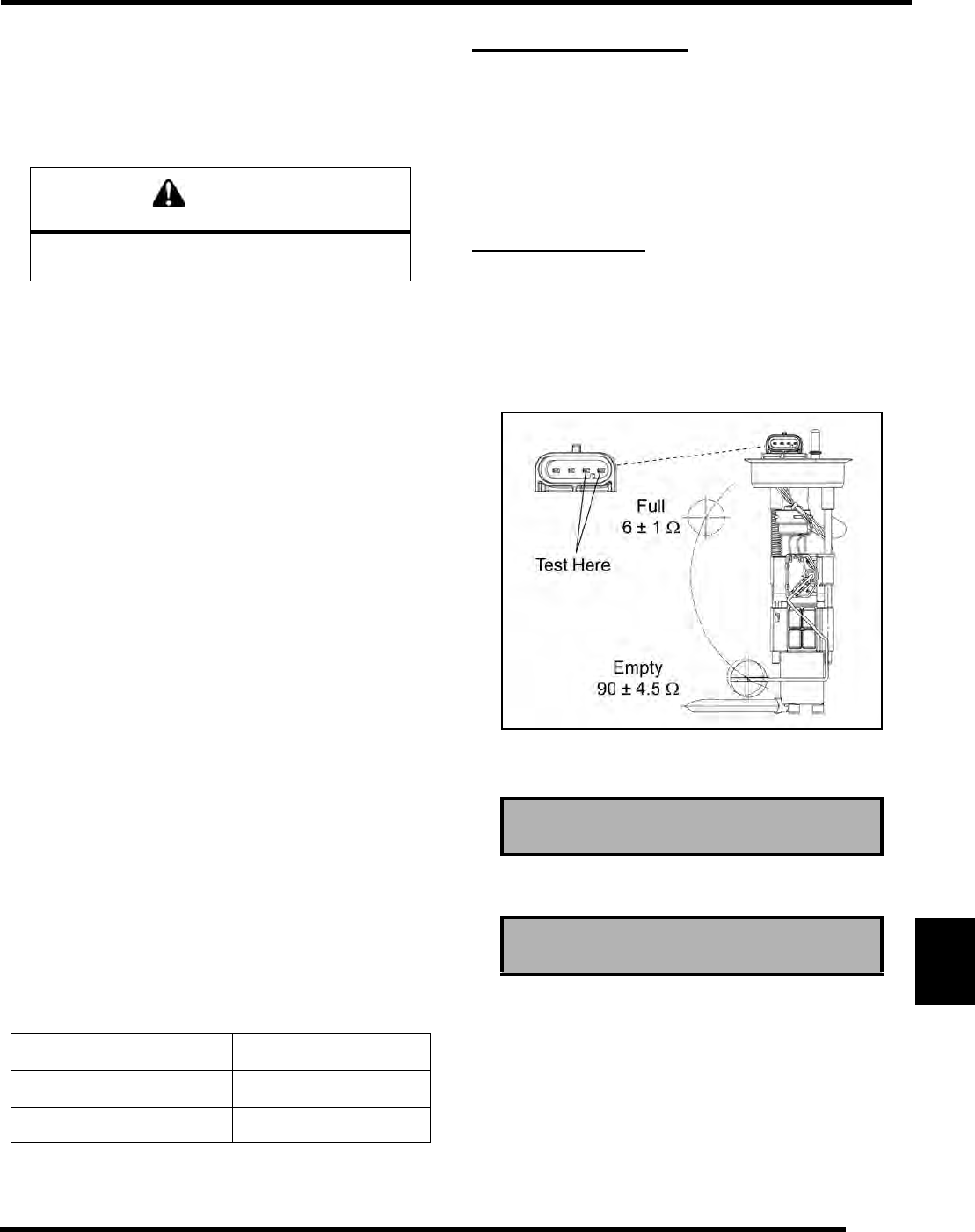

Testing

1. Drain the fuel tank and remove it from the vehicle (see

Chapter 4).

2. Set the fuel tank on a flat surface. Using an Ohm meter,

measure the resistance of the fuel sender as shown below.

3. Allow the sender float to sit in the empty position and

compare to specification.

4. Slowly tilt the tank so that gravity moves the sender float

to the full position and compare to specification.

5. If the readings are out of specification, or if the reading is

erratic or LCD display “sticks”, check the following before

replacing the fuel pump assembly:

• Loose float

• Float contact with tank

• Bent float rod

If none of the conditions exist, the fuel sender assembly is faulty.

Replace the fuel pump assembly (see Chapter 4).

CAUTION

Keep hands away from fan blades during

operation. Serious personal injury could result.

T

EMPERATURE F (C) RESISTANCE

68F (20 C) 2.5 k 6%

212

F (100 C) 186 2%

Fuel Sender - Empty: 90 ± 4.5

Fuel Sender - Full: 6 ± 1