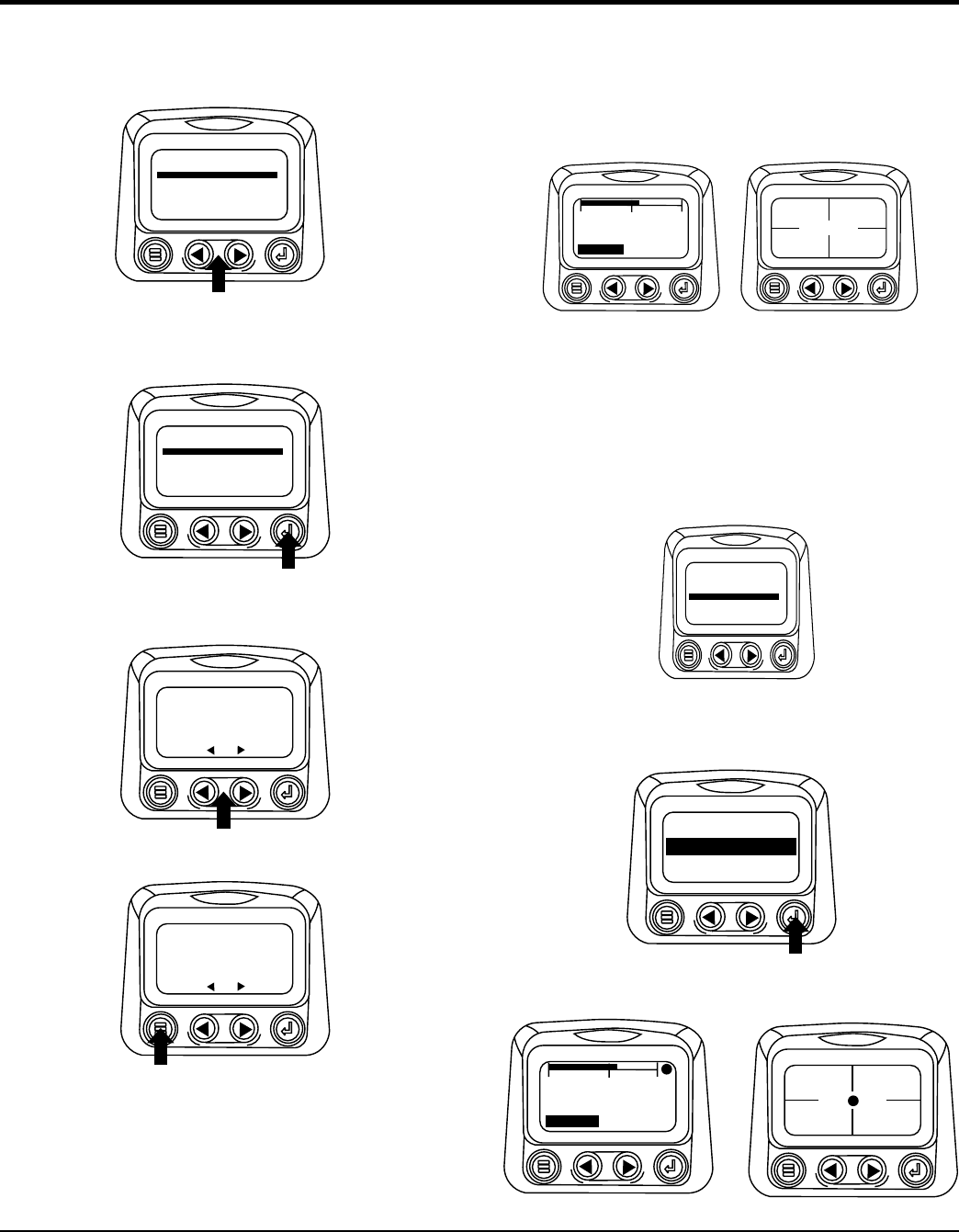

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

“Engine Configuration” menu item has been highlighted

.

3. Once the “Engine Configuration” menu item has been

highlighted touch the “Enter Button” to view the engine

configuration data.

4. Use the “Arrow Buttons” to scroll through the engine

configuration data.

5. Touch the “Menu Button” to return to the main menu.

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

GOTO1-UPDISPLAY

STOREDCODES

ADJUSTBACKLIGHT

SETUP1-UPDISPLAY

SETUP-4-UPDISPLAY

SELECTUNITS

ENGINECONFG

GOTO1-UPDISPLAY

STOREDCODES

ADJUSTBACKLIGHT

SETUP1-UPDISPLAY

SETUP-4-UPDISPLAY

SELECTUNITS

ENGINECONFG

ENGINE SPEEDPT 1

1800 RPM

MORE

ENGINE SPEEDPT 1

1800 RPM

MORE

Auxiliary Gage Fault

1. During normal operation the single or four parameter

screen will be displayed.

2. The PVA Series of auxiliary gages can be attached to

the PowerView. These auxiliary gages communicate

with the Modbus master PowerView via a daisy-chained

RS-485 port. If at any time during system initialization

or normal operation an auxiliary gage should fail, the

single or four parameter screen will be replaced with

the “MLink Gage Fault” message.

3. To acknowledge and “Hide” the fault and return to the

single or four parameter display, touch the “Enter

Button.

4. The display will return to the single or four parameter

screen.

COOL

1800 RPM

0

1500

3000

TEMP

ENG RPM

98%

14.2

57 PSI

1000 RPM

LOADRPM

BATTVOLT

ENGRPM

OILPRES

ENGINEOILPRESSURE

GAGENOTRESPONDING

1ofx

HIDE

ENGINEOILPRESSURE

GAGENOTRESPONDING

1ofx

HIDE

COOL

1800 RPM

0

1500

3000

TEMP!

ENG RPM

!

98%

14.2

!

57 PSI

1000 RPM

LOADRPM

BATTVOLT

ENGRPM

OILPRES

!

DIAGNOSTIC DISPLAY