72

Reassembly

KohlerEngines.com 20 690 01 Rev. F

Install Spark Plug

1. Check gap using wire feeler gauge. Adjust gap to

0.76 mm (0.03 in.).

2. Install plug into cylinder head.

3. Torque plug to 27 N·m (20 ft. lb.).

Install Heat Defl ector, Carburetor, Linkage and Air

Cleaner Base

1. If carburetor mounting stud was removed, reinstall it

in outer cylinder location (closest to head). Use an

E5 Torx

®

socket or two nuts tightened together, and

turn stud in until tight.

2. Make sure all gasket surfaces are clean and free of

any nicks or damage.

3. Install a new intake gasket onto carburetor stud,

then install heat defl ector. Curved section should be

down, toward engine. If defl ector contains a molded

protruding point, it should be towards back inserted

into intake port. Be sure protruding point goes

through large hole in gasket, to keep it aligned.

4. Models with one screw and one mounting stud only:

Insert a 3/16” diameter rod, approximately 4” long,

into open mounting hole in heat defl ector to serve as

a temporary alignment pin. Be careful not to force

rod or damage threads.

5. Install a new carburetor gasket onto mounting

stud(s) and/or alignment pin.

6. Attach choke and throttle linkages to carburetor and

install carburetor assembly. If governor lever was not

disconnected, slide it onto governor shaft with lever

up.

7. If carburetor has a fuel solenoid, fasten ground lead

to crankcase boss, with toothed washer between

eyelet terminal and boss. Torque screw to 8.0 N·m

(70 in. lb.). Connect solenoid power lead to wiring

harness and secure with a tie strap.

8. Connect fuel line to carburetor and secure with a

hose clamp.

9. Install air cleaner base (with fuel pump attached, if

equipped).

a. Install a new air cleaner base gasket. Check two

metal spacers are in air cleaner base mounting

holes and install base onto stud(s), and or

alignment pin. Make sure upper mounting tab is

positioned above closure plate boss. Install nut(s)

and fi nger tighten.

b. Models with one screw and one mounting stud

only: Apply hand pressure to keep parts from

shifting, then carefully remove alignment pin and

install DRY long M6 thread forming screw. DO

NOT OIL. Check to make sure all gaskets are still

in proper position.

c. Torque nut(s) to 5.5 N·m (48 in. lb.). Torque screw

to 8.0 N·m (70 in. lb.) into a new hole, or 5.5 N·m

(48 in. lb.) into a used hole, do not over tighten.

An M6 screw for upper tab will be installed when

blower housing is mounted.

10. Attach breather hose to valve cover and air cleaner

base.

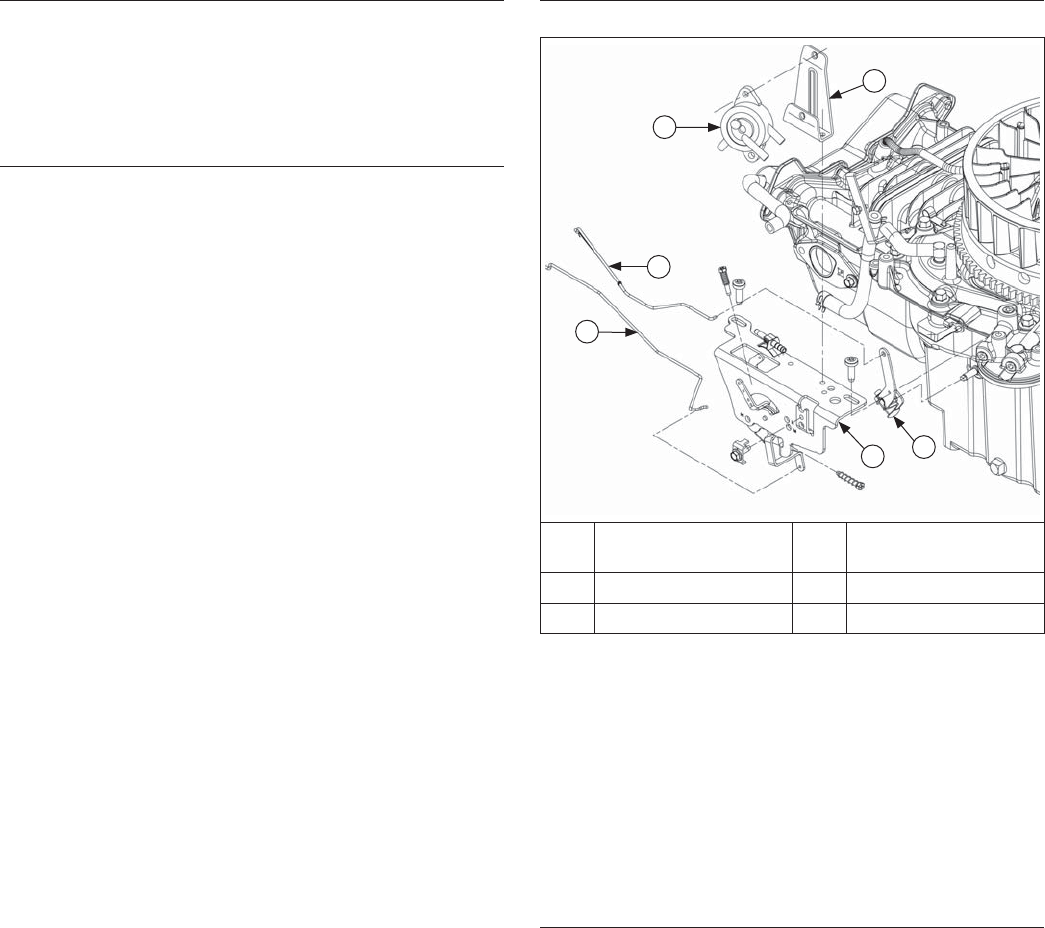

Install and Adjust Governor Lever

Speed Control Bracket Details

F

B

D

C

E

A

A Governor Lever B

Speed Control

Bracket

C Choke Linkage D Throttle Linkage

E Fuel Pump Bracket F Fuel Pump

NOTE: It is recommended a new governor lever be

installed whenever removal is performed.

1. Install governor lever onto governor shaft with lever

section up. Connect throttle linkage using black

linkage bushing.

2. Move governor lever toward carburetor, to limit of its

travel (wide-open throttle) and hold in this position.

Do not apply excessive pressure, fl exing or distorting

linkage. Grasp cross shaft with a pliers, and turn

shaft counterclockwise as far as it will go. Torque nut

to 7.0-8.5 N·m (60-75 in. lb.).

Mounting Speed Control Bracket

1. Attach governor spring to governor lever and throttle

lever of speed control bracket, in original holes. If

holes were not marked during disassembly, refer to

Governor Spring Location charts. Connect choke

linkage from carburetor to actuating lever of speed

control bracket.

2. Attach speed control bracket to mounting locations

on engine with M6 screws. Position bracket as

marked during disassembly. Torque screws to

11.0 N·m (95 in. lb.) into new holes, or 7.5 N·m

(65 in. lb.) into used holes.