67

Reassembly

20 690 01 Rev. F KohlerEngines.com

Install Flywheel Side Oil Seal

Lubricate outside diameter and lip of fl ywheel end oil

seal. Support closure plate and install oil seal. Using a

seal driver, drive seal to a depth of 5 mm (0.196 in.) in

seal bore.

Install Closure Plate Gasket, Closure Plate, and

Wiring Harness

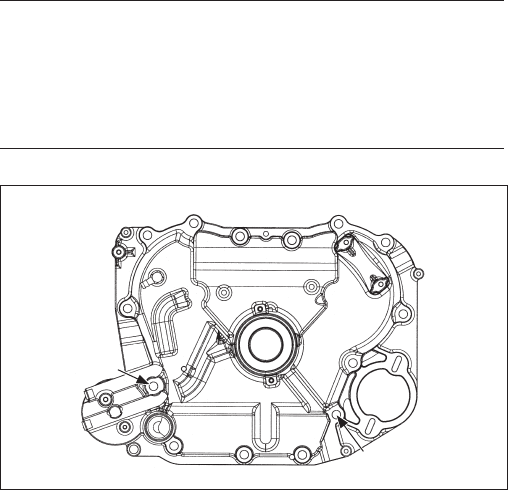

Closure Plate Fastener Torque Sequence

5

13

7

10

8

9

12

426

11

14

13

NOTE: A special gasket used between closure plate

and crankcase controls crankshaft endplay, no

shimming is required. Do not use RTV sealant in

place of gasket.

NOTE: Engines with fi rst generation balance weight:

Apply grease to outside fl at surfaces of balance

weight guide shoe. Position guide shoe so solid

end is toward crankshaft. Make sure guide shoe

stays in this position during step 2.

1. Make sure sealing surfaces of crankcase and

closure plate are clean, dry, and free of any nicks or

burrs. Install a new closure plate gasket onto

crankcase.

2. Ensure gasket, cover plate, and governor gear

assembly, have been properly assembled to closure

plate. Start closure plate onto crankcase. Be sure

guide shoe (models with First Generation Balance

Weight), is aligned with guide channel in closure

plate, and cam shafts and governor gear shaft are

aligned with their mating bearing surfaces. As

closure plate is lowered into fi nal position, rotate

crankshaft slightly to help engage governor gear.

3. Install screws securing closure plate to crankcase,

with any clamps for wiring harness and sheathed

RFI suppression spark plug lead (#5 location, if

equipped). If wiring harness was separated from

closure plate, route harness through clamps and slot

in closure plate. Close clamps to retain harness.

4. Torque closure plate fasteners to 24.5 N·m

(216 in. lb.) using sequence shown.