56

Disassembly/Inspection and Service

KohlerEngines.com 20 690 01 Rev. F

4. If wiring harness needs to be separated from closure

plate, pry open clamps and pull out through slot.

Disassemble Closure Plate

NOTE: Governor gear is held onto shaft by small

molded tabs in gear. When gear is removed

these tabs are destroyed and gear must be

replaced. Governor gear removal is required for

closure plate disassembly and cleaning of oil

passages.

1. Remove governor gear and regulating pin assembly.

Gently pry upward using blades of two small

screwdrivers.

2. Remove screws securing oil passage cover to

closure plate. Remove cover and gasket.

Governor Gear and Shaft Inspection

Inspect governor gear teeth. Look for any evidence of

worn, chipped, or cracked teeth. If one or more of these

problems is noted, replace governor gear.

Gear is held onto governor shaft by molded tabs, which

are damaged when gear is removed. Never reuse gear

once it has been pulled from shaft. Replace governor

shaft only if it is damaged or worn.

Remove Governor Shaft

1. Remove blower housing, fl ywheel, and cooling fan.

2. Remove stator and crankshaft key.

3. Remove closure plate screws and closure plate.

4. Rotate engine to top dead center aligning timing

marks on crankshaft and cam gears.

5. Remove governor gear assembly and regulating pin

from closure plate with two small screwdrivers.

6. Locate governor pin from fl ywheel side. With a small

punch, drive pin out of closure plate. This could also

be done with a press. Do not remove governor pin

with a vise grip or pliers, you may damage closure

plate.

7. Remove any old gasket material from mating

surfaces of crankcase and closure plate. Use an

aerosol gasket remover to help loosen any old

gasket material. Do not scrape surfaces, as any

scratches, nicks, or burrs can result in leaks.

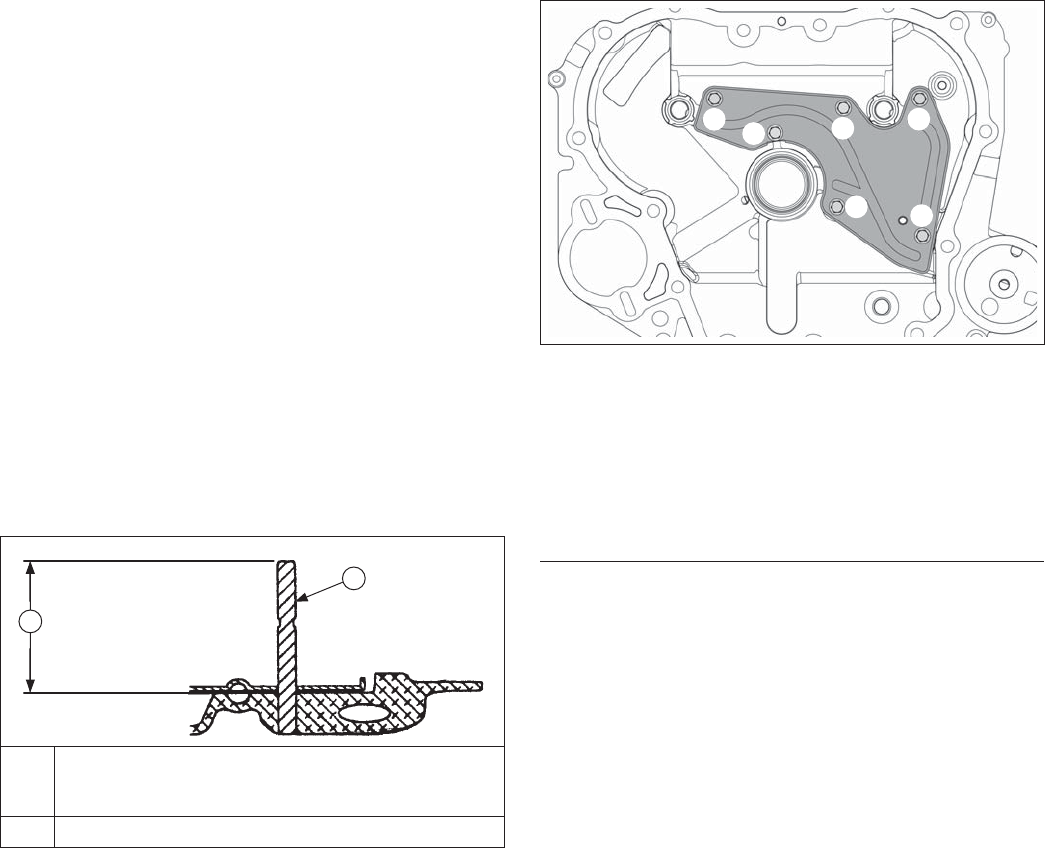

Install Governor Shaft

Governor Shaft Components and Details

A

B

A

44.50 mm (1.750 in.) To Gasket Surface - Before

Oil Passage Cover Plate and Gasket are

Assembled

B Governor Gear Shaft

1. Install new pin by pressing or lightly tapping it into

closure plate. It must be installed so that it protrudes

44.50 mm (1.750 in.), plus or minus 0.101 mm

(0.004 in.) above crankcase boss.

2. Install new governor regulating pin and governor

gear assembly.

3. Make sure governor gear assembly rotates freely.

4. Check that timing marks are still aligned.

5. Install a new closure plate gasket and install closure

plate. Torque fasteners to 24.5 N·m (216 in. lb.).

6. Complete engine reassembly following Reassembly

procedures.

7. When engine reassembly is completed, reset initial

governor adjustment according to procedure in

Governor System.

Closure Plate and Passage Cover Inspection and

Service

Passage Cover Torque Sequence

6

1

5

2

3

4

If disassembly was performed, inspect and ensure

oil passages in closure plate and passage cover are

completely clean and not obstructed in any way. Check

straightness of passage cover if required, against a fl at

surface.

Use a new passage cover gasket and install passage

cover onto closure plate. Reinstall mounting screws and

torque to 4.0 N·m (35 in. lb.), following sequence.

Remove Cam Gears, Cam Shafts, and Oil Pump

NOTE: ACR weight and spring normally captured by

thrust washer and installation of closure plate,

will fall out if exhaust cam gear is turned upside

down.

NOTE: Cam gear assemblies may contain either two or

four rivets.

NOTE: Engine Serial No. 332740003 and lower, use a

rubber outlet between oil pump outlet and lower

bearing area. Some models use an open seal

with an internal passage to feed oil to lower

bearing. Some models use a closed or solid

seal, and crankshaft is crossed-drilled to feed oil

to lower bearing.

Engine Serial No. 332740003 and higher, outlet

of oil pump is closed and no rubber seal is used.