37

Electrical System

20 690 01 Rev. F KohlerEngines.com

Electronic Ignition System Tests

NOTE: Ignition tester must be used to test ignition on these engines. Use of any other tester can result in inaccurate

fi ndings. Battery on unit must be fully charged and properly connected before performing tests (a battery that

is hooked up or charged backward will crank engine but it won’t have spark). Be certain drive is in neutral and

all external loads are disconnected.

Test Ignition Systems

NOTE: If engine starts or runs during testing, you may need to ground kill lead to shut it down. Because you have

interrupted kill circuit, it may not stop using switch.

Isolate and verify trouble is within engine.

1. Locate connectors where wiring harnesses from engine and equipment are joined. Separate connectors and

remove white kill lead from engine connector. Rejoin connectors and position or insulate kill lead terminal so it

cannot touch ground. Try to start engine to verify whether reported problem is still present.

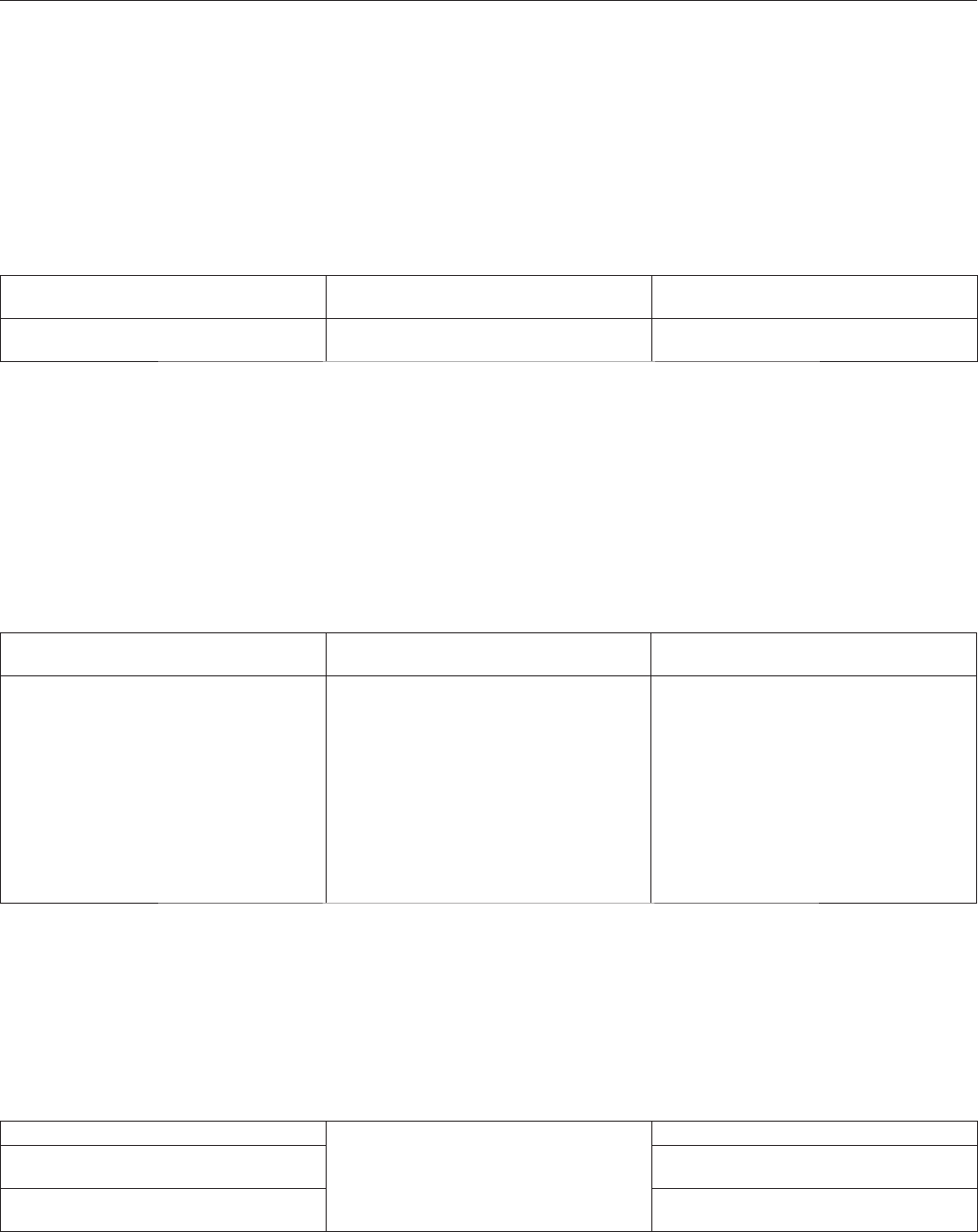

Condition Possible Cause Conclusion

Problem goes away. Electrical System Check key switch, wires, connections,

safety interlocks, etc.

Problem persists. Ignition or Electrical System Leave kill lead isolated until all testing

is completed.

Test for Spark

NOTE: To maintain engine speeds normally obtained during cranking, do not remove engine spark plug.

1. Make sure spark plug lead is connected to spark plug.

2. Check condition of spark plug. Make sure gap is set to 0.76 mm (0.030 in.). If plug is in good condition, check/

adjust gap and reinstall.

3. a. Test for spark with ignition tester. Disconnect spark plug lead and connect it to post terminal of tester. Connect

clip to a good ground, not spark plug.

b. Make sure engine ignition switch, kill switch, or key switch is in RUN position.

4. Crank engine (minimum speed 500 RPM), and observe tester. Visible and audible sparks should be produced.

Condition Possible Cause Conclusion

Audible and visible sparks are

produced.

Ignition Module

Ignition module is OK.

Audible and visible sparks are not

produced.

Ignition Module or Electrical System Make sure engine ignition switch,

kill switch, or key switch is in RUN

position.

Check wires and terminals of ignition

module and other components for

accidental grounding and damaged

insulation.

If wires and terminals are OK, ignition

module is probably faulty and should

be replaced. Test module further using

an ohmmeter.

Test Ignition Module with Ohmmeter

NOTE: This test cannot be performed unless module has been fi red at least once.

Measure resistance of module secondary using an ohmmeter.

1. Zero ohmmeter.

2. Connect one ohmmeter lead to laminations. Connect other lead to spark plug terminal of high-tension lead.

3. With ohmmeter leads connected in this manner, resistance of secondary should be 7,900 to 18,400 ohms. Refer

to Disassembly and Reassembly for complete ignition module removal and installation procedures.

Condition Possible Cause Conclusion

Resistance is within specifi ed range. Module Secondary Module secondary is OK.

Resistance is low or 0 ohms. Module secondary is shorted.

Replace module.

Resistance is high or infi nity ohms. Module secondary is open. Replace

module.