PART C: 999 CC AND

1108 CC WITH C514 TYPE

TRANSMISSIONS

Description

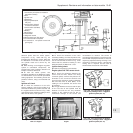

1 A new 5-speed transmission was

introduced to selected models during 1992.

Identified by the way reverse gear is engaged.

The gear knob needs to pressed downwards

whilst pushing the lever to the extreme right.

2 The new design includes control cables as

well as rods for gear selection, see Fig. 13.94.

Maintenance ¡

3 At the time of writing, no maintenance

instructions were available, however should

selecting gears become difficult, check the

following.

4 The gear lever should rest vertically in

neutral. If it does not, alter the gear selector

adjustable rod, as appropriate.

5 Whilst turning the adjustment nut,

counterhold with a 10 mm open ended

spanner, located in the notch built into the

sleeve. Refer to Fig. 13.95.

13 Driveshafts

Inboard joint boots (non-Turbo

models, September 1987 on) -

modification

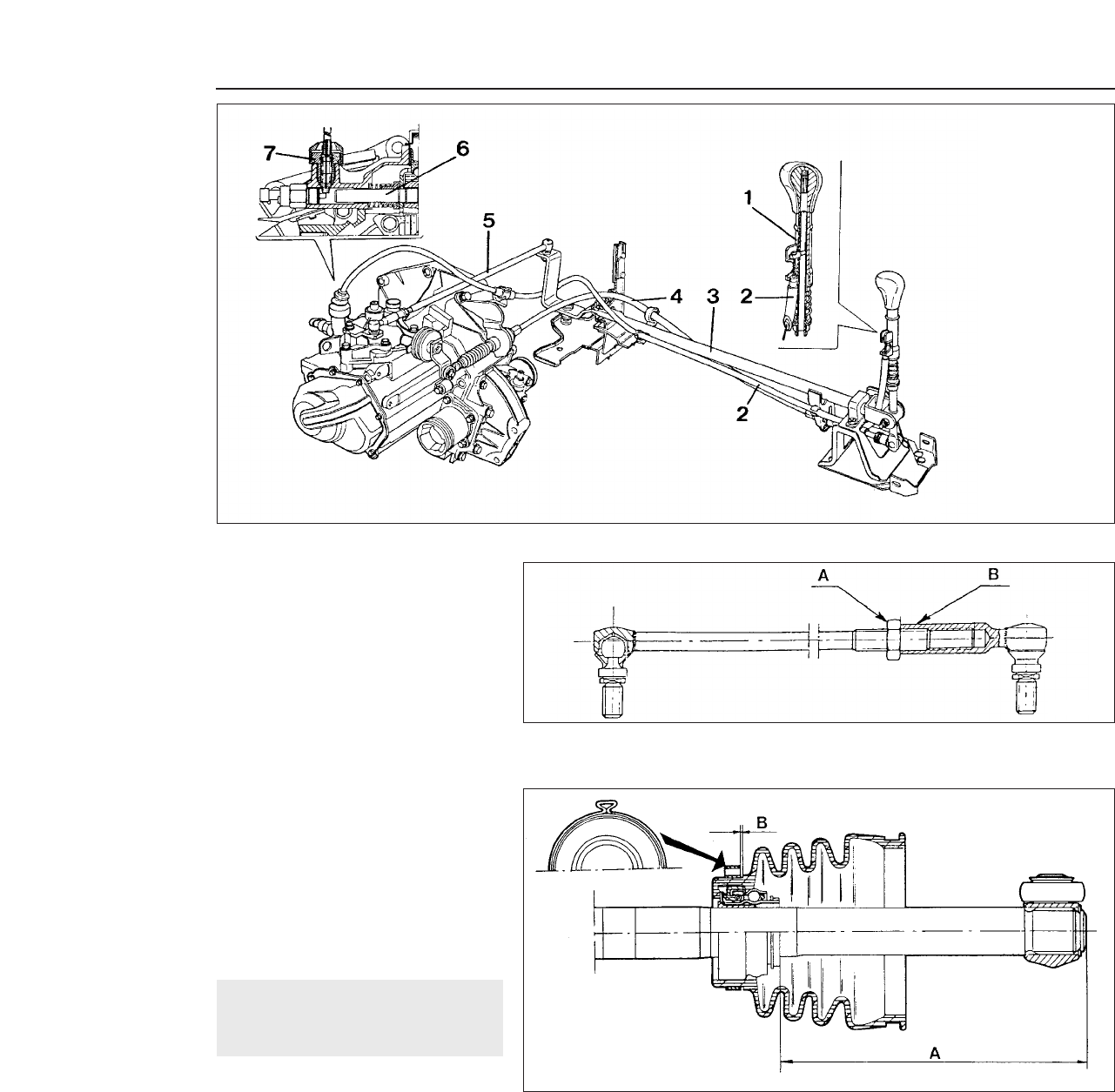

1 Modified boots have been fitted to the

differential ends of the driveshafts on non-

Turbo models produced after September 1987.

2 The new boots incorporate a seal/bearing

assembly, and it is very important when a

boot is being fitted to the driveshaft that it is

located as shown in Fig. 13.96.

13•98 Supplement: Revisions and information on later models

Fig. 13.96 Driveshaft boot positioning diagram - later non-Turbo models (Sec 13)

Left-hand shaft

With 4-speed transmission,

A = 143.0 mm (5.63 in)

With 5-speed transmission,

A = 133.0 mm (5.24 in)

Right-hand shaft

With 4-speed transmission,

A = 123.0 mm (4.84 in)

With 5-speed transmission,

A = 108.9 mm (4.25 in)

Fig. 13.94 C514 type 5-speed transmission

1 Sliding part of gear

lever

2 Reverse gear inhibitor

device flexible control

cable

3 Gear selector control

rod

4 Gear engagement

control cable

5 Gear selector

adjustable control rod

6 Gear selector and

engagement control

shaft

7 Reverse gear inhibitor

device

B = 0 to 1 mm (0 to 0.04 in)

Fig. 13.95 Gear selector adjustable rod (C514 type transmissions)

A Adjusting nut B Location of notch in outer sleeve