adjustments described in this sub-Section,

however, will require removal of the

carburettor.

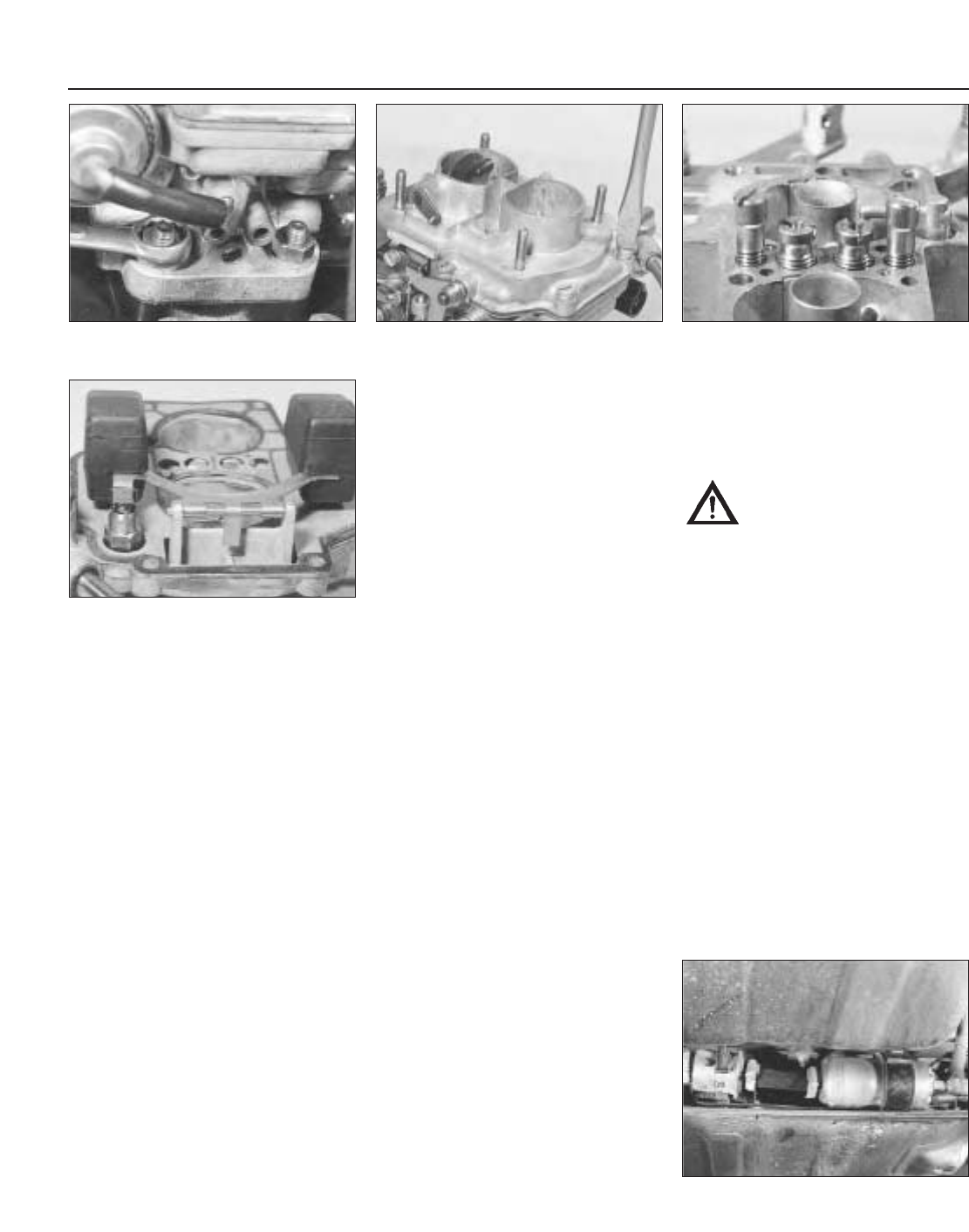

39 Disconnect the short, curved diaphragm

hose from the top cover.

40 Extract the top cover screws, lift the cover

from the carburettor body, and rotate it in

order to release the cranked choke control

rod from its key hole (photo). Mop out the fuel

and clean the jets.

41 Check the jet sizes and other components

against those listed in the Specifications, in

case a previous owner has substituted

incorrect components (photo).

42 Overhaul procedures are generally as

given in Chapter 3, Section 14 for the Weber

30/32 DMTR, but use the Specifications listed

in this Chapter. Additional overhaul

procedures are given here.

Fuel inlet needle valve

43 If a high float level causing flooding of the

carburettor has been evident, first check that

the inlet valve housing is tight, and its washer

is sealing satisfactorily. A leak here will cause

fuel to bypass the inlet valve.

44 If the needle valve is to be renewed,

remove it in the following way.

45 Access to the fuel inlet needle valve is

obtained by carefully tapping out the float arm

pivot pin. Take care, the pivot pin pillars are

very brittle (photo).

46 Unscrew the fuel inlet valve body and

remove the valve and washer.

47 When refitting the new valve, always use a

new sealing washer.

Float stroke (travel) - see Fig. 3.10

48 The float stroke should be between 42.5

and 43.5 mm when measured from the top

cover gasket. Adjust if necessary by bending

the tab on the end of the arm.

Accelerator pump

49 Adjustment of the accelerator pump is

very rarely required, but if performance is

suspect, carry out the following operations.

50 Fill the carburettor float chamber and then

operate the throttle valve plate lever several

times to prime the pump.

51 Position a test tube under the accelerator

pump jet and give ten full strokes of the

throttle lever, pausing between each stroke to

allow fuel to finish dripping.

52 The total volume of fuel collected should

be as specified. Adjust the nut on the pump

control if necessary to increase or decrease

the volume of fuel ejected.

General

53 When the stage is reached where the

valve plate spindle bushes have worn, then

the carburettor should be renewed complete.

54 When reassembling the carburettor, use

new gaskets which can be obtained in a repair

pack.

Carburettor (Weber 32 ICEV

61/250 and DMTE 30/32,

DMTE 30/150) - general

55 These carburettor types are fitted to later

models according to engine type. They are

similar in structure and operation to their

equivalents described in Chapter 3. Reference

can therefore be made to that Chapter for the

description and any operations concerning

them, but refer to Section 2 of this Chapter for

their specifications.

Carburettor (Solex

C 30/32-CIC 8) - description

56 This carburettor is fitted as an alternative

to the Weber unit on 1116 cc models

produced for certain markets. The removal,

refitting and overhaul procedures are

essentially the same as described earlier for

the Weber carburettors.

PART C:

BOSCH LE2-JETRONIC

FUEL INJECTION SYSTEM

Description

Warning: Refer to the beginning

of this Section before starting

any work.

1 The Bosch LE2-Jetronic fuel injection

system, fitted to the 1301 cc Turbo ie model,

is an electronically controlled multi-point

injection (MPi) system.

2 The fuel injectors are fed at constant

pressure in relation to inlet manifold vacuum

pressure.

3 The system electronic control unit (ECU)

actuates the injectors for variable duration,

and so supplies the precise volume of fuel

required for any given engine speed and load

condition.

4 The ECU also monitors the air induction, air

temperature, coolant temperature and throttle

opening as additional parameters to compute

the required opening of the fuel injectors,

giving maximum power with fuel economy.

Fuel supply system

5 The fuel supply system consists of an

electric pump and primary filter, located

adjacent to the fuel tank. A fuel pressure peak

damper is located next to the pump (photo).

6 Fuel is then pumped through a filter to the

fuel rail and injectors. The injectors are of the

13•66 Supplement: Revisions and information on later models

9C.5 Electric fuel pump/filter/pressure

damper assembly location on a 1301 cc

Turbo ie model

9B.41 Jets on the Weber 30/32 DMTE

carburettor (top cover removed)

9B.45 Float pivot arrangement and needle

valve on the Weber 30/32 DMTE

carburettor

9B.40 Unscrewing a top cover screw from

the Weber 30/32 DMTE carburettor

9B.37F Unscrewing a carburettor fixing nut