DUAL COMPRESSORS AND DUAL REFRIGERATION CIR-

CUITS (090-150 and 216-300 Units) are provided. Two com-

pressors, each on its own independent circuit, provide standby

reliability and high operating efficiency.

ADVANCED DESIGN of evaporator and condenser coils pro-

vides optimum heat transfer and cooling efficiency. Coils are

computer-designed with advanced heat transfer surfaces, and

are fabricated of copper tubing with aluminum fins.

COMMERCIAL STRENGTH BASE RAILS (full-perimeter on

036-150 units) with built-in rigging capability allow easy rigging

of unit.

WEATHER-RESISTANT CABINET is built for durability in any

climate. The cabinet is made of pre-painted, galvanized steel for

long life and high-quality appearance.

LOW-AMBIENT OPERATION is provided standard on most

units. The 036-150 units and the 240 units operate in cooling

down to 25 F as shipped from the factory. The 180 units operate

down to 40 F, the 216 units operate down to 35 F, and the

300 units operate down to 48 F. Low-ambient kits are not re-

quired for most applications.

HERMETICALLY-SEALED COMPRESSORS on the 036-150

units prevent contamination to help promote longer life and de-

pendable operation. The 180-300 units have semi-hermetic

compressors.

COMPRESSOR VIBRATION ISOLATION MOUNTING on all

units eliminates noise-causing vibration transmission into the

conditioned space.

CRANKCASE HEATERS on the 180-300 units keep the oil free

of refrigerant during the off cycle for added compressor life and

reliability. Crankcase heaters are not necessary on the 036-150

units due to high-side crankcase design (072,150 units) and low

refrigerant charge levels (036-150 units).

POWER AND CONTROL CONNECTIONS are made on the

same side of the unit to simplify installation.

STANDARD WARRANTIES include 1 year on parts, with an ad-

ditional 4 years on compressors (036-180 units). Additional ex-

tended warranties are also available.

3 TO 6 TON UNITS WEIGH LESS THAN 500 LB as standard

from the factory. This can eliminate the need for structural en-

gineering approval on replacement jobs.

BELT-DRIVEN EVAPORATOR-FAN MOTORS are standard on

all 6 to 25 ton units, allowing adjustment of the available static

pressure to meet the job requirements of even the most de-

manding applications. Belt-driven evaporator-fan motors are

available as a factory-installed option on the 3 to 5 ton units.

FACTORY-INSTALLED OPTIONS

DESCRIPTION AND USAGE

Durablade (036-150) and Standard Integrated (180-300)

Economizers — The economizer will allow a fixed percentage

(between 0 and 100%) outdoor ventilation air into the unit any

time the evaporator fan is running.A dry-bulb thermostat placed

outdoors will bring in up to 100% outdoor air whenever the tem-

perature of the outdoor air alone will adequately provide cooling.

If the economizer alone cannot provide enough cooling, then si-

multaneous economizer and compressor operation will provide

the most economical operation.

SUGGESTED USE:

• To allow a fixed percentage of outdoor air any time the evapo-

rator fan is on, or operates in economizer mode if outdoor air

can provide cooling, but closes when the evaporator fan is off

to prevent cold backdrafts and wasted energy.

• To reduce energy usage. Use whenever the number of hours

of operation at below 55 F is significant.

• The damper may be used on either vertical or horizontal

applications.

Parablade Economizer (036-150 Units) — The unique design

of the Parablade economizer saves energy while providing eco-

nomical and reliable cooling. The new design uses a parallel-

opposed blade damper to permit outdoor ventilation air to enter

the unit any time the evaporator fan is running. The economizer

will permit cooling using 100% outdoor air whenever outdoor air

alone will provide adequate cooling. If the economizer alone

cannot provide enough cooling, then simultaneous economizer

and compressor operations will provide the most economical

operation. The economizer also has built-in spring return for re-

liable close-on-power loss. The Parablade design incorporates

standard enthalpy controls.

SUGGESTED USE:

• To allow a fixed percentage of outdoor air on vertical applica-

tions any time the evaporator fan is on, or to operate in econo-

mizer mode if outdoor air can provide cooling, but closes

when the evaporator fan is off to prevent cold backdrafts and

wasted energy.

• To reduce energy usage. Use whenever the number of hours

of operation at below 55 F is significant.

NOTE: Indoor-air quality (IAQ) restrictions require enthalpy con-

trols to help regulate humidity in the occupied space.

25% and 50% Manual Outdoor-Air Damper — Package con-

sists of a damper which can be set at 25% or 50% (036-150)

outdoor air. The package includes a rainhood and birdscreen.

SUGGESTED USE:

• To allow a fixed percentage of outdoor air for ventilation under

all conditions.

• The damper may be used on either vertical or horizontal

applications.

NOTE: The 25% manual outdoor-air damper will be factory

installed whenever the factory-installed economizer is not

chosen on the 180-300 units.

Alternate Evaporator-Fan Motors (036-060,120,150 Units)

and Drives (036-060,090,120,150 Units) — Alternate motors

and/or drives allow operation of the evaporator fan at conditions

outside the range of the standard factory motor and drive

combination.

SUGGESTED USE:

• When higher static/airflow is required to meet job conditions.

CONTENTS

Page

Model Description ............................4

ARI Capacity Ratings .........................5

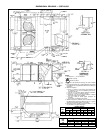

Dimensional Drawings .......................6-13

Specifications ............................14-16

Selection Procedure .........................17

Gross Cooling Capacities ....................18-25

Air Delivery ..............................26-46

Electrical Data............................49-54

Operating Sequence .........................55

Typical Wiring Schematic .....................56,57

Typical Installation .........................58,59

Application Data ..........................60-63

Electric Heater Capacities .....................64

Engineers’ Specification Guide .................65,66

2