INSTALLATION DIRECTIVE MAY 2006

28

V08 ENT M75

-

M11

-

M12

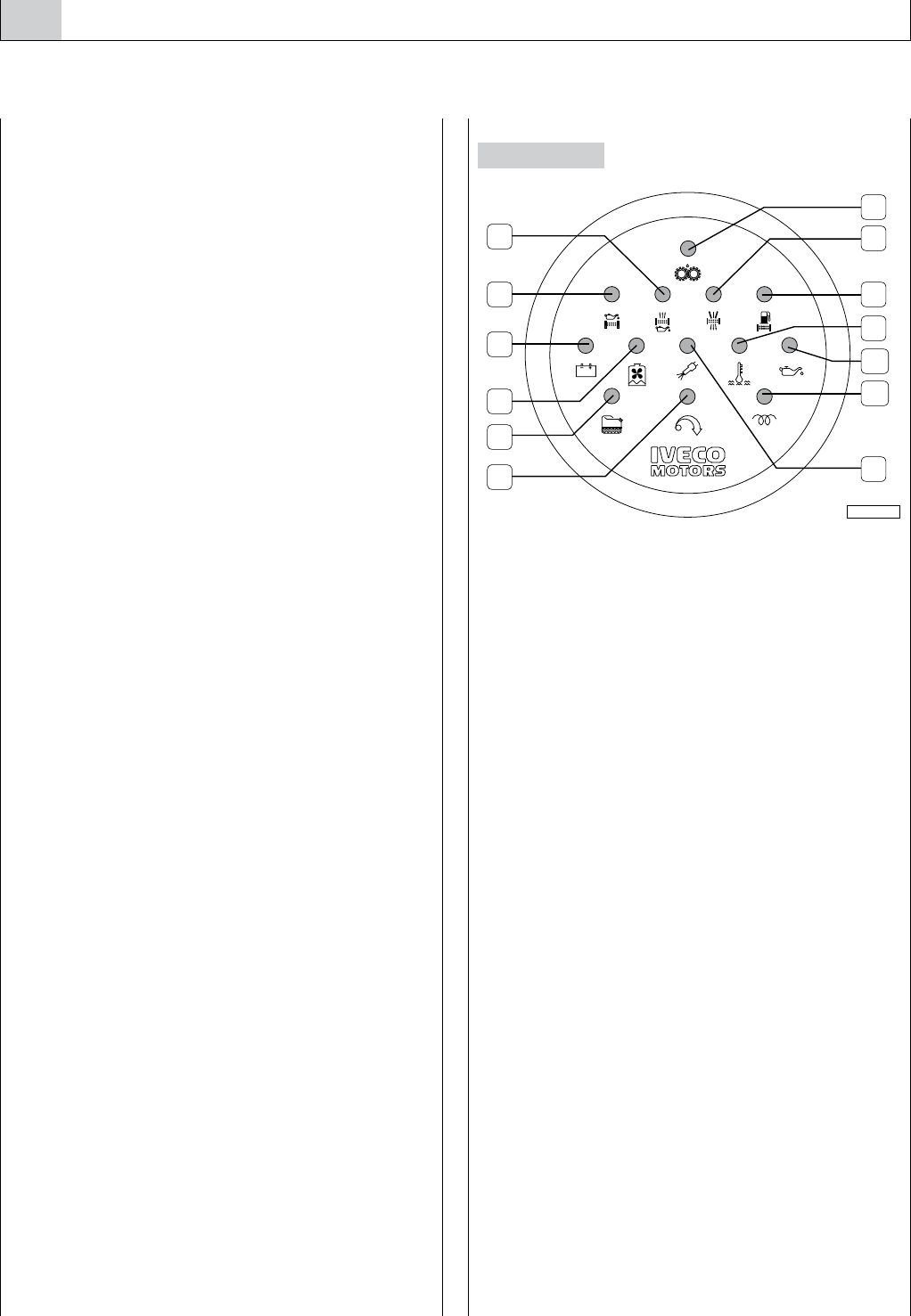

Indications and Alarms Module

1. Engine overspeed (SSV) - 2. Presence of water in the fuel

prefilter (SAC) - 3. Low engine coolant level (SBLA) -

4. Alternator anomaly (SS) - 5. Clogged oil filter (SIFO)-

6. Clogged blow-by filter (SIFB) - 7. Pre-lubrication in progress

(SP) - 8. Clogged air filter (SIFA) - 9. Clogged fuel filter (SIFC) -

10. High coolant temperature (SATA) - 11. Low oil pressure

(SBPO) - 12. Pre/post heating (SCP) - 13. EDC Malfunction (EDC).

The Indications and Alarm Module comprises the indicator

lights and the electronic alarm interface, timing and stor-

age circuit. It is programmed in such a way that when it is

powered, all indicator lights are lighted, with the exception

of those for “pre-lubrication”, “pre-post heating” and “EDC”

failure and a sound signal is emitted by the buzzer.

The buzzer may be silenced before the end of the test, acting

on the appropriate control.

During the starting phase and for the subsequent 15 sec-

onds, needed to stabilize the low oil pressure signal, all the

module’s functions are inhibited; once this time interval has

elapsed, every alarm state detected by the sensors will cause

the associated indicator to be lighted and the buzzer to be

powered; the exceptions are the “pre-lubrication” and “pre-

post heating” indicators, given only visually.

When a new alarm state is detected, the indicator light will

flash to highlight the occurrence with respect to any others

which may be ongoing at the time. When the sound alarm is

shut off, the light indicator will remain lighted and the alarm

will be stored until the engine is stopped.

The standard set-up of the V08 ENT M75, V08 ENT M11

and V08 ENT M12 provides for use of the indicators: SBLA,

SIFA, SIFC, SIFO, EDC, SS.

2

4

8

13

1

3

5

6

9

12

10

11

7

04_234_N

Installation

In order to drill holes on the area where the panel is to be

mounted, refer to the dimensions indicated in Chapter 11.

Operation of the panel

After completing the electrical connections and engine

preparation, perform the tests required for the first start, as

described in Chapter 18.

Verify the proper operation of the panel, proceeding as fol-

lows:

o Make sure that the “ENGINE ROOM / BRIDGE” switch

of the Relay Box is in the “BRIDGE” position, then

turn the key switch to the first position and verify that

the instruments are powered and the Indications and

Alarms Module runs the alarm test for about 5 seconds

according to the procedures set out below.

o Once the test is complete, only the indications prescribed

for the engine not running must remain lighted: e.g.

“alternator charge” and “low oil pressure”; the analog

instruments must provide values consistent with the

relevant physical parameters.

Testing the engine start function

Turn the key switch in the second position and release it

quickly; the start function is fully controlled by the ECU and

begins when the key is released.

Checking indications

After starting the engine, verify whether the operating

modes of the Indications and Alarms Module are similar to

those set out below.

Using appropriate measuring instruments, verify the consis-

tency of the indications provided by the analog instruments.

Verify the indication of the panel revolution counter, compar-

ing it with the one measured by a reference instrument; if the

indication is different, proceed as described below.

Testing the engine stop function

The engine is stopped and the panel is disabled by returning

the key switch to the resting or zero position.

The panel has an engine stop push-button whose function is

only enabled in versions where the engine stops as a result

of the excitation of an actuator, i.e. engine versions requiring

certification by Certification Bodies.

Figure 26