INSTALLATION DIRECTIVE

15

V08 ENT M75

-

M11

-

M12

MAY 2006

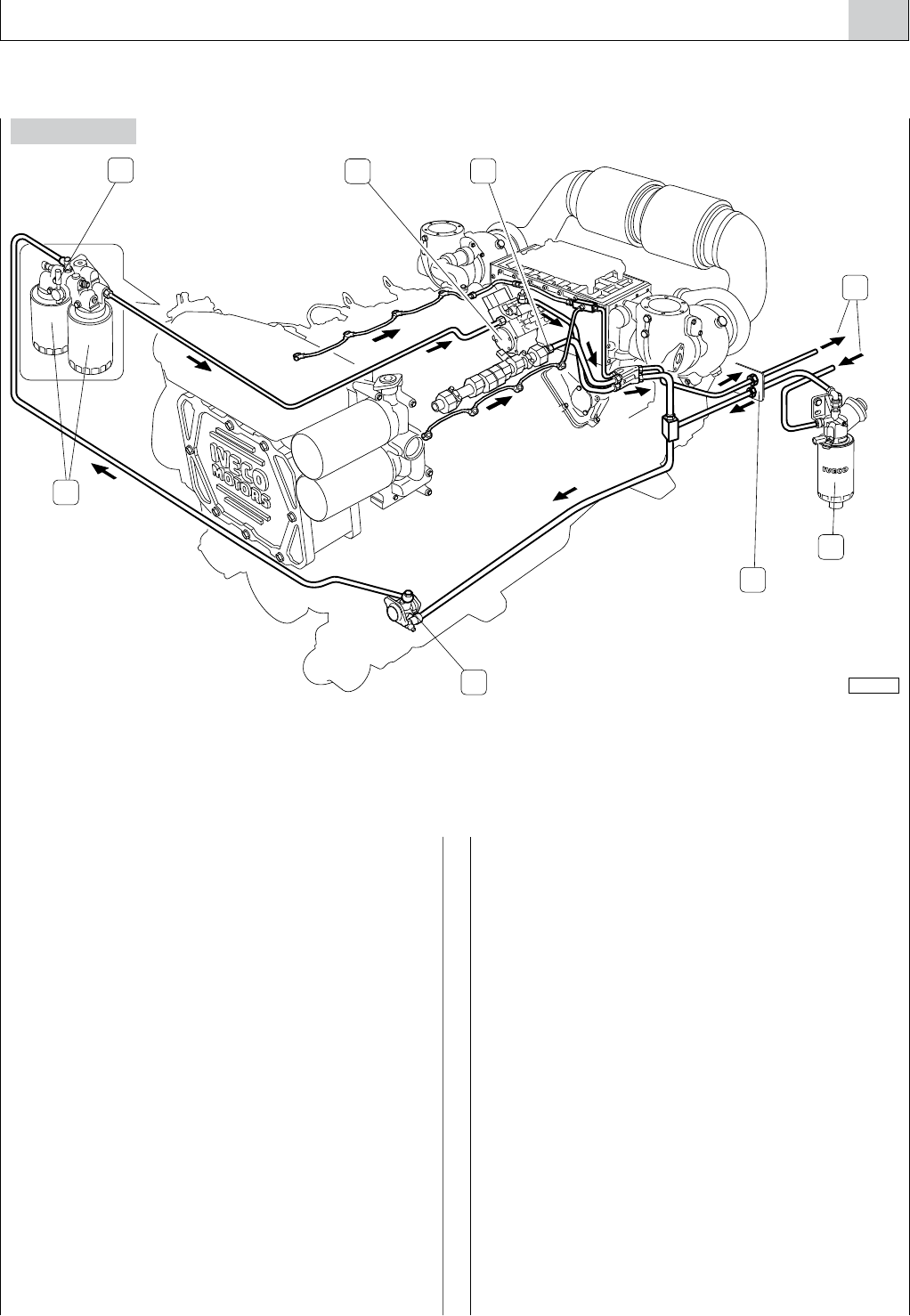

7. FUEL LINE

Figure 7

For the installation, the following connections are required:

- from the tank to the prefilter

- from the prefilter to fitting to engine inlet

- from engine outlet fitting to the tank recirculation

Prefilter

The prefilter with priming pump, supplied separately from

the engine, must be fastened near the tank, in a relatively low

point of the line to allow for easy replacement the filtering

cartridge and/or the operation of the hand pump. Avoid the

use of additional mesh or paper filters along the feed lines

between prefilter and engine. To avoid introducing impuri-

ties in the feeding lines inside the engine, do not place filter

cartridges pre-filled with fuel in the system.

Materials Characteristics

The fuel tank and the suction and return assembly must

withstand the continuous abrasion caused by a flow of fuel

oil of 250 l/h at a temperature of 90°C without noticeable

deformation or wear or release of material. Use of metal

tanks, preferably made of iron alloys, is allowed, provided

they are connected to the negative terminal of the battery

to prevent the accumulation of electrostatic charges.

Tanks must be provided with vents to avoid exceeding an

internal pressure of ± 5kPa (± 0.5 m of H

2

O column); their

shape and the suction assembly must be such as to assure a

suction at the maximum longitudinal and transverse inclina-

tion allowed for the boat, with a residual quantity of fuel oil

considered “reserve”.

The suction inlet should be positioned in such a way as to

avoid taking in sludge. The return flow must be in such a way

as to facilitate the mixing of the returning fuel with the fuel

in the tank. If the tank is lower than the filter, then the return

pipe must always be submerged. The pipes and union fittings

of the fuel line must withstand a fuel oil flow rate of 250

l/h at a temperature of 90°C and a pressure of 3 bar (300

kPa) without noticeable deformation, wear or release of

material. Metal tubes, preferably made of iron alloys, are rec-

ommended, taking care to connect each individual segment

to engine ground to avoid the accumulation of electrostatic

charges and inserting a vibration damper elastic joint on each

segment. The pipes used must be certified according to the

relevant Countries’ rules or to the standards issued by clas-

sification Bodies.

05_012_V

1

2

4

5

6

7

8

3

1. Return and suction flows from the tank - 2. Prefilter - 3. Fuel fitting support - 4. Low pressure supply pump -

5. Fuel filters - 6. Lever for switching fuel filters - 7. Common rail high pressure injection pump - 8. Rail overpressure valve.