Series 220/221 Instruction Manual Chapter 2 Installation

Insertion Procedure for Meters with a Compression Connection

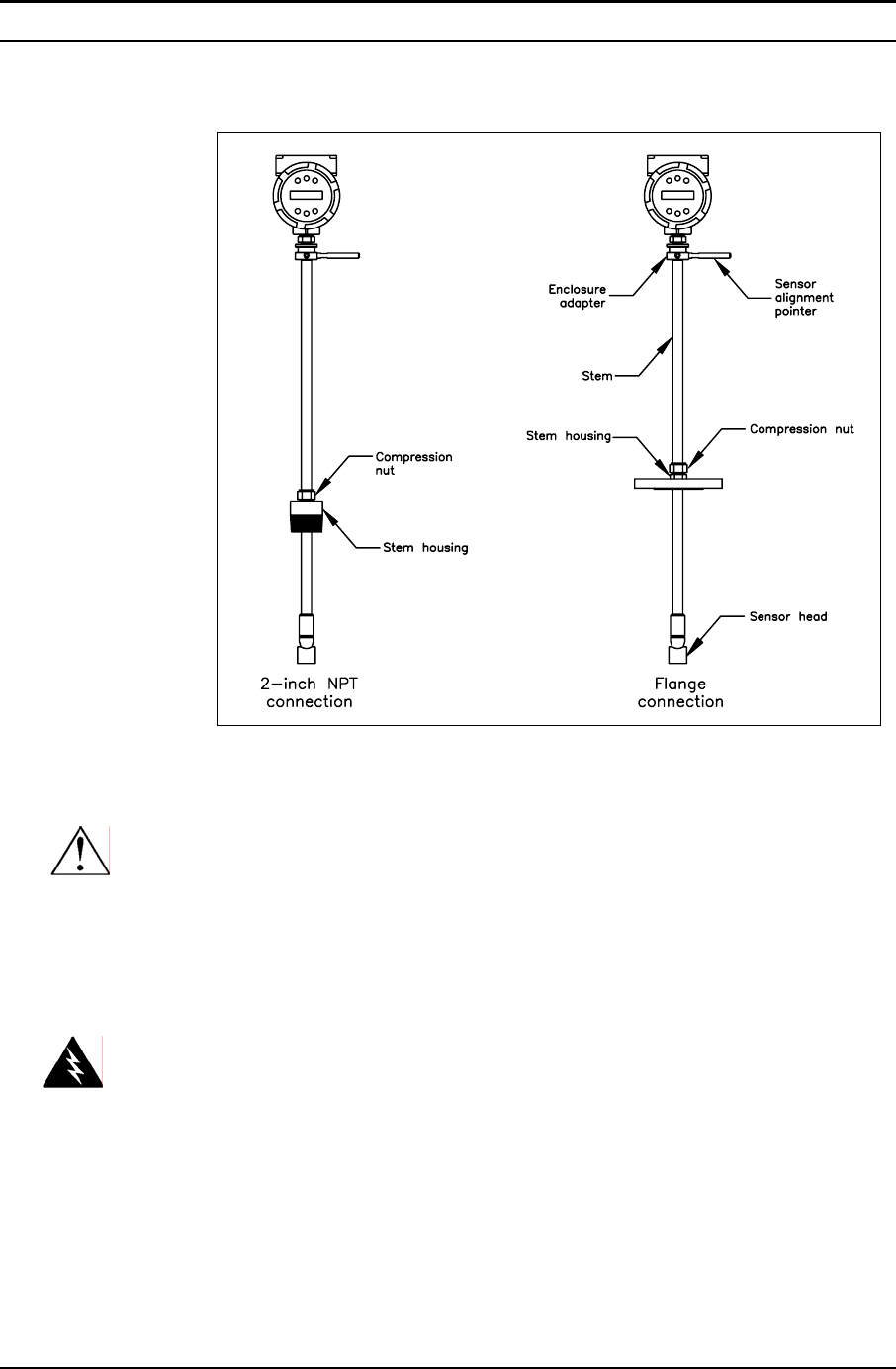

Figure 2-7. Flow Meter with Compression Type Fitting

1. Calculate the required sensor probe insertion length.

Caution!

The sensor alignment

pointer must point

downstream, in the

direction of flow.

2. Fully retract the stem until the sensor head is touching the bottom of the

stem housing. Slightly tighten the compression nut to prevent slippage.

3. Bolt or screw the flow meter assembly into the process connection. Use

Teflon tape or pipe sealant to improve the seal and prevent seizing on NPT

styles.

4. Hold the meter securely while loosening the compression fitting. Insert

the sensor into the pipe until the calculated insertion length, I, is meas-

ured between the base of the enclosure adapter and the top of the stem

housing, or to the raised face of the flanged version. Do not force the

stem into the pipe.

Warning!

To avoid serious injury,

DO NOT loosen the

compression fitting

under pressure.

5. Align the sensor head using the sensor alignment pointer. Adjust the

alignment pointer parallel to the pipe and pointing downstream.

6. Tighten the compression fitting to lock the stem in position. When the

compression fitting is tightened, the position is permanent.

IM-22 2-11