Chapter 2 Installation Series 220/221 Instruction Manual

Series 221 Insertion Flow Meter Installation

Prepare the pipeline for installation using either a cold tap or hot tap method

described on the following pages. Refer to a standard code for all pipe tap-

ping operations. The following tapping instructions are general in nature and

intended for guideline purposes only. Before installing the meter, review the

mounting position and isolation value requirements given below.

Mounting Position

Allow clearance between the electronics enclosure top and any other obstruc-

tion when the meter is fully retracted.

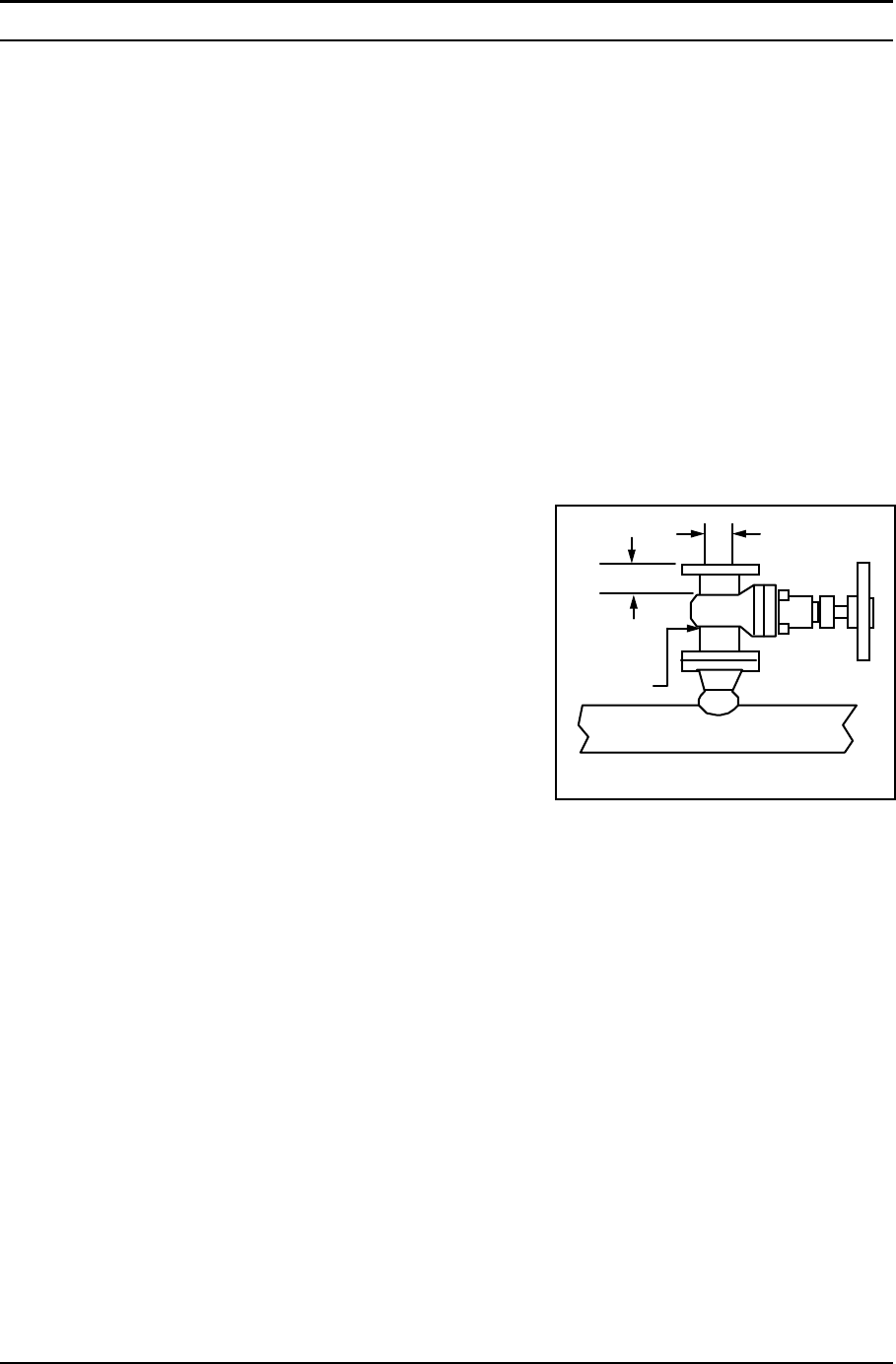

Isolation Valve Selection

An isolation valve is available as an option with Series 221 meters. If you

supply the isolation valve, it must meet the following requirements:

2-6 IM-22

1. A minimum valve bore diameter

of 1.875 inches is required, and

the valve’s body size should be

two inches. Normally, gate

valves are used.

2. Verify that the valve’s body and

flange rating are within the flow

meter’s maximum operating

pressure and temperature.

3. Choose an isolation valve with

at least two inches existing between the flange face and the gate portion

of the valve. This ensures that the flow meter’s sensor head will not in-

terfere with the operation of the isolation valve.

1.875-inch min.

valve bore

2-inch min.

2-inch

valve size

Isolation Valve Requirements