Chapter 2 Installation Series 220/221 Instruction Manual

Hot Tap Guidelines

Warning!

Hot tapping must be

performed by a trained

professional. US. regula-

tions often require a hot

tap permit. The manufac-

turer of the hot tap

equipment and/or the

contractor performing the

hot tap is responsible for

providing proof of such a

permit.

Refer to a standard code for all pipe tapping operations. The following tap-

ping instructions are general in nature and intended for guideline purposes

only.

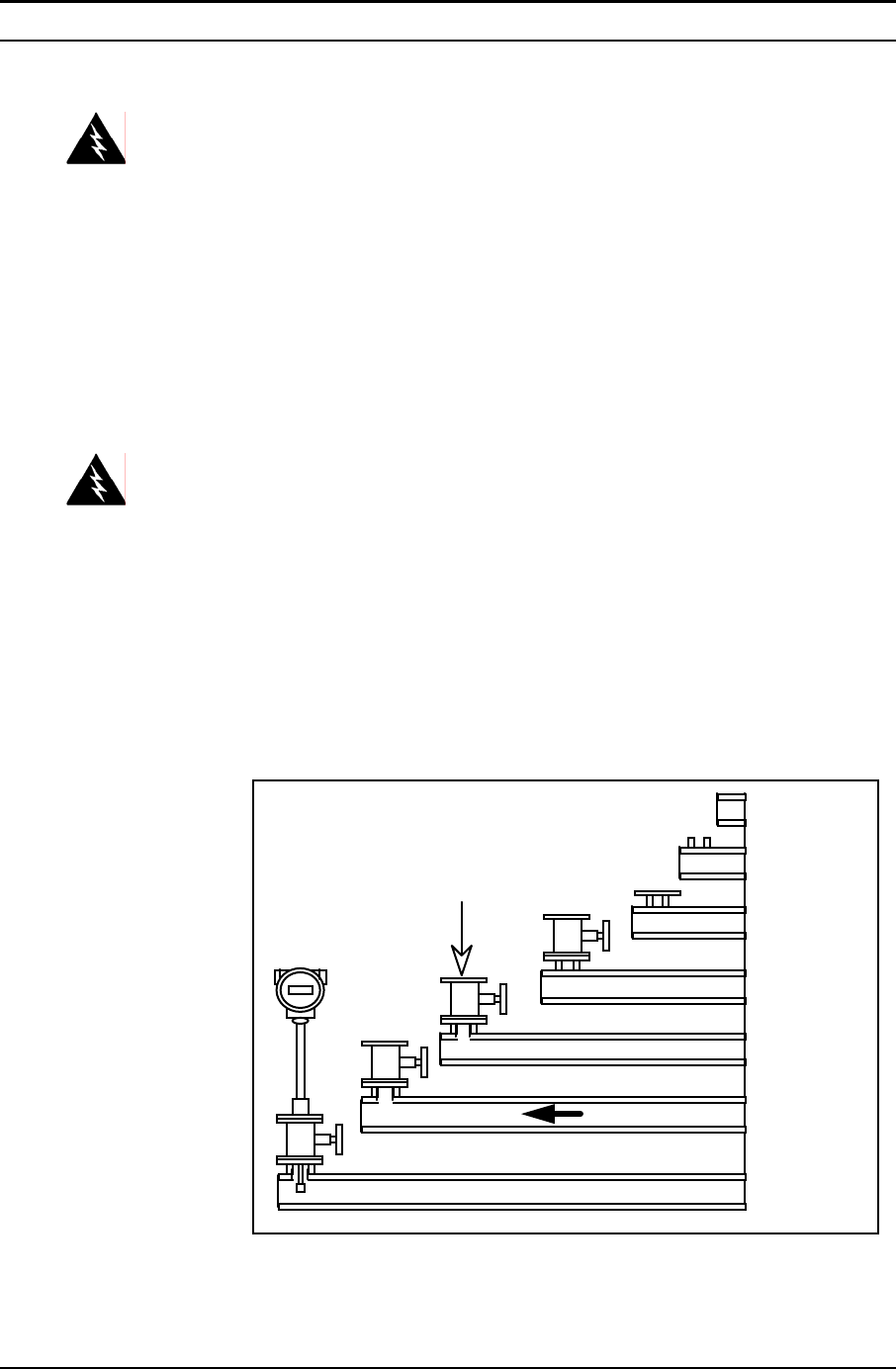

1. Confirm that the installation site meets the minimum upstream and

downstream pipe diameter requirements.

2. Weld a two inch mounting adapter on the pipe. Make sure the mounting

adapter is within ± 5° perpendicular to the pipe centerline (see previous

page). The pipe opening must be at least 1.875 inches in diameter.

3. Connect a two inch process connection on the mounting adapter.

4. Connect an isolation valve on the process connection. The valve’s full

open bore must be at least 1.875 inches in diameter.

Warning!

All flow meter connec-

tions, isolation valves and

fittings for hot tapping

must have the same or

higher pressure rating as

the main pipeline.

5. Hot tap the pipe.

6. Close the isolation valve. Run a static pressure check on the welds. If

pressure loss or leaks are detected, repair the joint and re-test.

7. Connect the flow meter to the isolation valve.

8. Calculate the sensor probe insertion depth as described on the following

pages. Insert the sensor probe assembly into the pipe.

Check upstream and

downstream piping

requirements

Weld mounting

adapter

Connect process

connection

(flange or NPT)

Connect

isolation valve

Test for leaks,

purge pipe

Hot tap pipe

Connect meter to

valve, calculate

insertion depth,

install flow meter

FLOW

Figure 2-5. Hot Tap Sequence

2-8 IM-22