300-302 Series Page 16 of 31

can be dissipated by radiation, conduction, or convection. The radiation term is negligible due to the

low temperatures used by the sensor, and because the sensor construction preferentially favors the

conductive and convective heat transfer modes. The thermal energy of each heater will then be

dissipated by conduction down the stainless steel sensor tube, conduction to the insulating foam, plus

the convection due to the mass flow of the sensed gas.

Because great care is taken to wind the resistive heater coils symmetrically about the midpoint of the

tube, it is assumed that the heat conducted along the sensor tube from the upstream heater will be

equal to the heat conducted through the tube from the downstream heater. Similarly, the heat

conducted from the upstream and downstream coils to the foam insulation surrounding them is

assumed to be equal, based on the symmetry of the sensor construction.

Since the sensor tube inlet and outlet are linked by an aluminum ambient bar, the high thermal

conductivity of the bar provides a ‘thermal short’, constraining the ends of the sensor tube to be at

equal surface temperature. Moreover, the tube ends and the aluminum ambient bar have intimate

thermal communication with the main flow passageway prescribed by the main stainless steel flow

meter body. This further constrains each end of the sensor tube to be equal to the ambient gas

temperature.

Further, since the length of each heater section is nearly 21 times greater than the inside tube

diameter, the mean gas temperature at the tubes axial midpoint is approximately equal to the tube

surface temperature at that point. Recall that the outside of the sensor tube is well insulated from the

surroundings; therefore the tube surface temperature at the axial midpoint is very close to the

operating temperature of the heater coils. The mean temperature of the gas stream is then

approximately the same as the heater temperature. Assuming the mean gas temperature is equal to

the heater temperature, it can be shown that the differential pressure is:

The value of the constant pressure specific heat of a

gas is virtually constant over small changes in

temperature. By maintaining both heaters at the

same, constant temperature difference above the

ambient gas stream temperature, the difference in

heater power is a function only of the mass flow

rate. Fluctuations in ambient gas temperature

which cause errors in conventional mass flow

sensors are avoided; the resistance of the ambient

sensing coil changes proportionally with the ambient

temperature fluctuations, causing the closed loop

control to vary the bridge voltage such that the

heater resistance changes proportionally to the

ambient temperature fluctuation.

The power supplied to each of the 2 heater coils is

easily obtained by measuring the voltage across the

heater, shown as V

2

on Figure 3.2, and the voltage

across the fixed resistor R

1

. Since R

1

is in series with

the heater R

H

they have the same current flowing

through them. The electrical power supplied to a

given heater is then calculated:

()

1

221

R

VVV −

=Ρ

With a constant differential temperature applied to each heater coil and no mass flow through the

sensor the difference in heater power will be zero. As the mass flow rate through the sensor tube is

increased, heat is transferred from the upstream heater to the gas stream. This heat loss from the

(3.1)

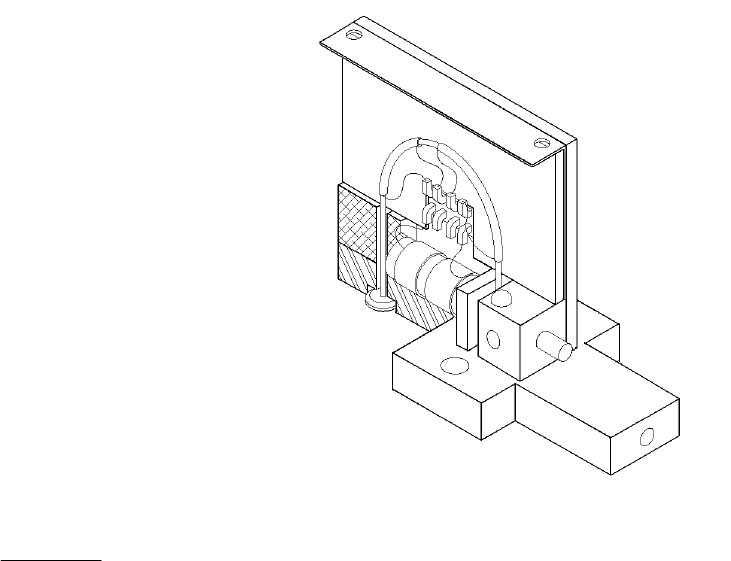

Fig. 3.1

(

3.2

)

()

ambientheaterpd

TTCmP −=−

•

2P

μ