4G1 ENGINE (E-W) -

Crankshaft and Cylinder Block

11A-12-3

PWEE9520

E

Nov. 1995Mitsubishi Motors Corporation

REMOVAL SERVICE POINTS

A

A

"

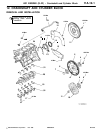

OIL PRESSURE SWITCH REMOVAL

(1) Disconnect the oil pressure switch terminals.

(2) Using the special tool, remove the oil pressure switch.

Caution

The thread is coated with sealant. Take care not to

bend it when removing the oil pressure switch.

INSPECTION

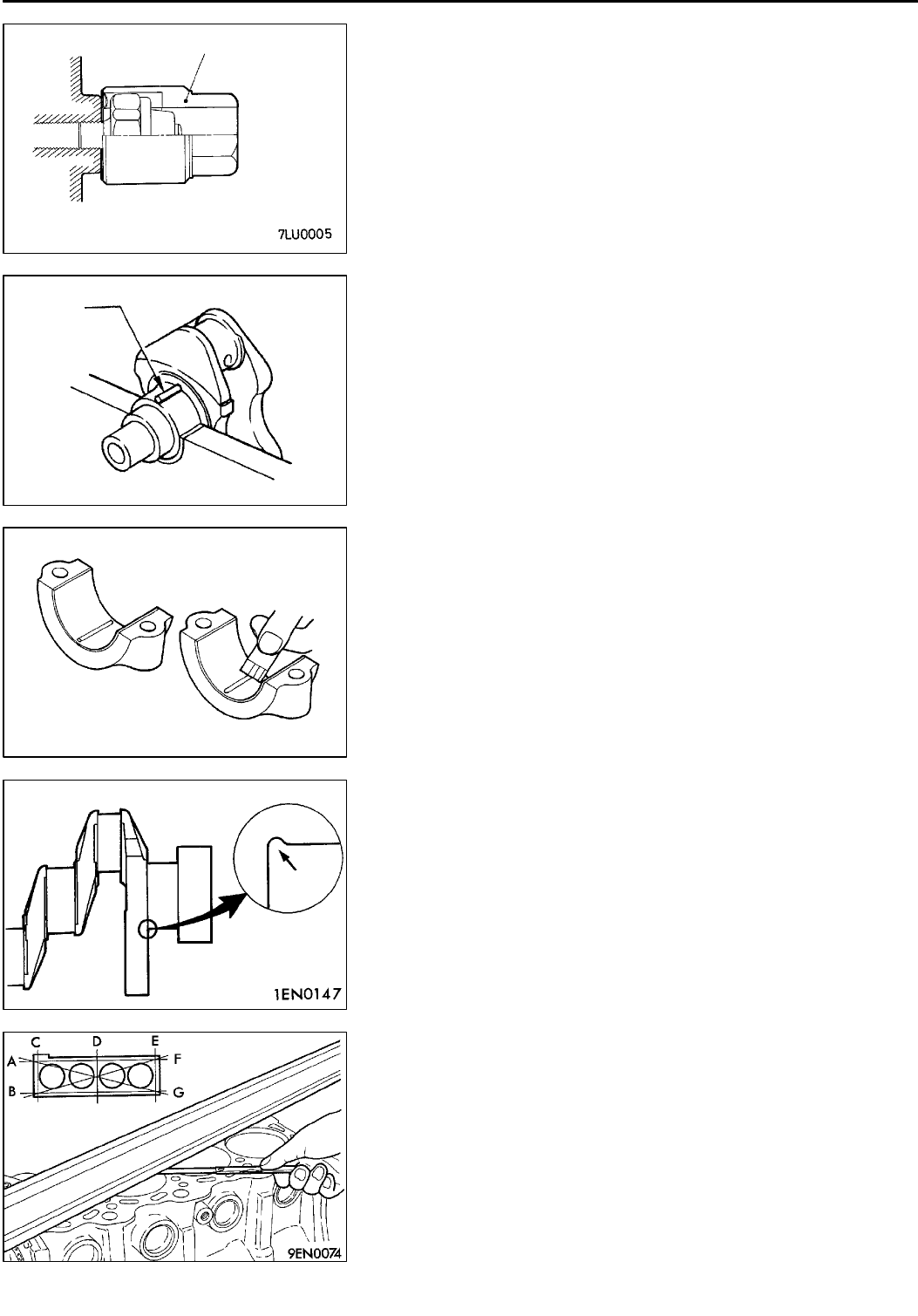

1. CRANKSHAFT OIL CLEARANCE

The crankshaft oil clearance can be measured easily

using a plastic gauge.

To check the crankshaft oil clearance with a plastic gauge,

carry ou t th e following procedure:

(1) Wipe all oil off th e crankshaft journal and the bearing’s

inside surface.

(2) Install the crankshaft.

(3) Cut the plastic gauge such that its length matches the

width of the bearing, then place it on the journal along

the journal’s axis.

(4) Gently fit the crankshaft bearing cap and tighten the bolts

to the specified torque.

(5) Remove the bolts and gently remove the crankshaft

bearing cap.

(6) Using the scale printed on the plastic gauge bag, measure

the plastic gauge’s crushed section at its widest point.

Standard value: 0.02 - 0.04 mm

Limit: 0.1 mm

NOTE

The crankshaft pins and journals are fillet-rolled and must

not be machined to undersize dimensions.

2. CYLINDER BLOCK

(1) Visually check for cracks, rust, and corrosion, a nd inspect

the cylinder block using a flaw detecting agent. Rectify

defects where possible or replace the cylinder block.

(2) Ensure that the top surface is free of gasket chips and

other foreign material. Check the cylinder block’s top

surface for distortion using a straight edge and thickness

gauge.

Standard value: 0.05 mm

Limit: 0.1 mm

(3) Check the cylinder walls for cracks and seizure marks.

If defects are evident, bore all the cylinders to oversize

or replace t he cylinder block.

PWEE9520-A

E

Dec. 1998Mitsubishi Motors Corporation Revised

MD998054

Plastic

gauge

6EN0550

1EN0271

Fillet-rolled section