4G1 ENGINE (E-W) -

Pistons and Connecting Rods

11A-11-7

PWEE9520

E

Nov. 1995Mitsubishi Motors Corporation

"

F

A

CONNECTING ROD CAP INSTALLATION

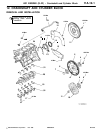

(1) Aligning t he marks made during disassembly, fit the

bearing cap onto the connecting rod. If the connecting

rod is new and has no index mark, ensure that the bearing

locking notches are both on the same side.

(2) Check that the connecting rod big en d side clearance

confirms with specifications.

Standard value: 0.10 - 0.25 mm

Limit: 0.4 mm

"

G

A

CONNECTING ROD CAP NUT INSTALLATION

Caution

To fit the connecting rod cap nuts with the cylinder

head in place, the spark plugs must be removed

beforehand.

(1) The connecting rod bolts and nuts utilize the plastic region

tightening method. The bolts must therefore be checked

for stretching before reuse. To check a bolt for stretching,

screw the nut down the entire length of the thread by

hand. Unless the nut turns smoothly all the way, the bolt’s

threaded section is stretched and the bolt must be

replaced.

(2) Before fitting the nuts, apply engine oil to their threads

and seating surfaces.

(3) Fit the nuts onto the bolts and turn them until they are

finger-tight. After this, the nuts must be tightened

alternately to ensure correct fitting of the cap.

(4) Tighten the nuts to a torque of 17 Nm.

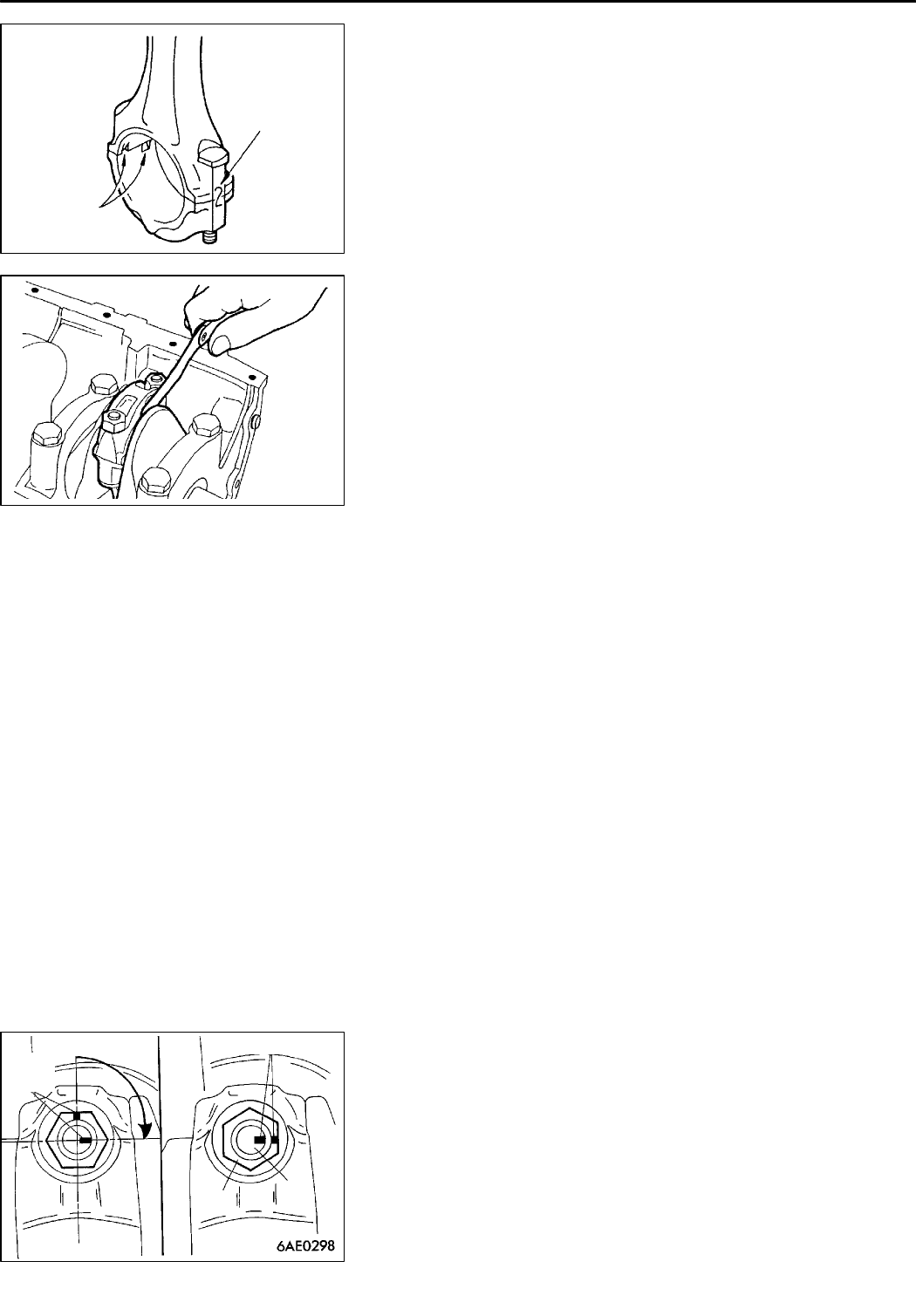

(5) Make a paint mark on the top of each nut as shown.

(6) Make paint marks on the bolts 90 to 100

_

clockwise from

the paint marks on the nuts.

(7) Turn the nuts until their paint marks are aligned with the

paint marks on the bolts.

PWEE9520-A

E

Dec. 1998Mitsubishi Motors Corporation Revised

Cylinder No.

DEN0051

Locking notch

1EN0276

90

_

- 100

_

Paint

mark

Paint mark

Nut

Bolt