4G1 ENGINE (E-W) -

Pistons and Connecting Rods

11A-11-2

PWEE9520

E

Nov. 1995Mitsubishi Motors Corporation

REMOVAL SERVICE POINTS

A

A

"

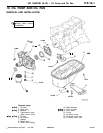

CONNECTING ROD CAP REMOVAL

(1) Mark th e cylinder number on the side of the connecting

rod big end to facilitate reassembly.

A

B

"

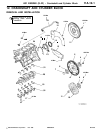

PISTON PIN REMOVAL

(1) Insert the Push Rod (special tool) from the front arrow

mark side, then fit guide D.

(2) Mount the piston a n d connecting rod assembly on the

Piston Pin Setting Base (special tool) with the piston’s

front mark pointing upward.

(3) Remove the piston pin using a press.

NOTE

After removing the piston pin, keep the piston, piston

pin, and connecting rod together. Do not allow pistons,

piston pins, and connecting rods from different cylinders

to become mixed up.

INSPECTION

1. PISTON RINGS

(1) Check the piston ring side clearance. If the clearance

exceeds th e specified limit, replace t h e ring or piston,

or both.

Standard values:

No. 1 ring: 0.03 - 0.07 mm

No. 2 ring: 0.02 - 0.06 mm

Limits:

No. 1 ring: 0.1 mm

No. 2 ring: 0.1 mm

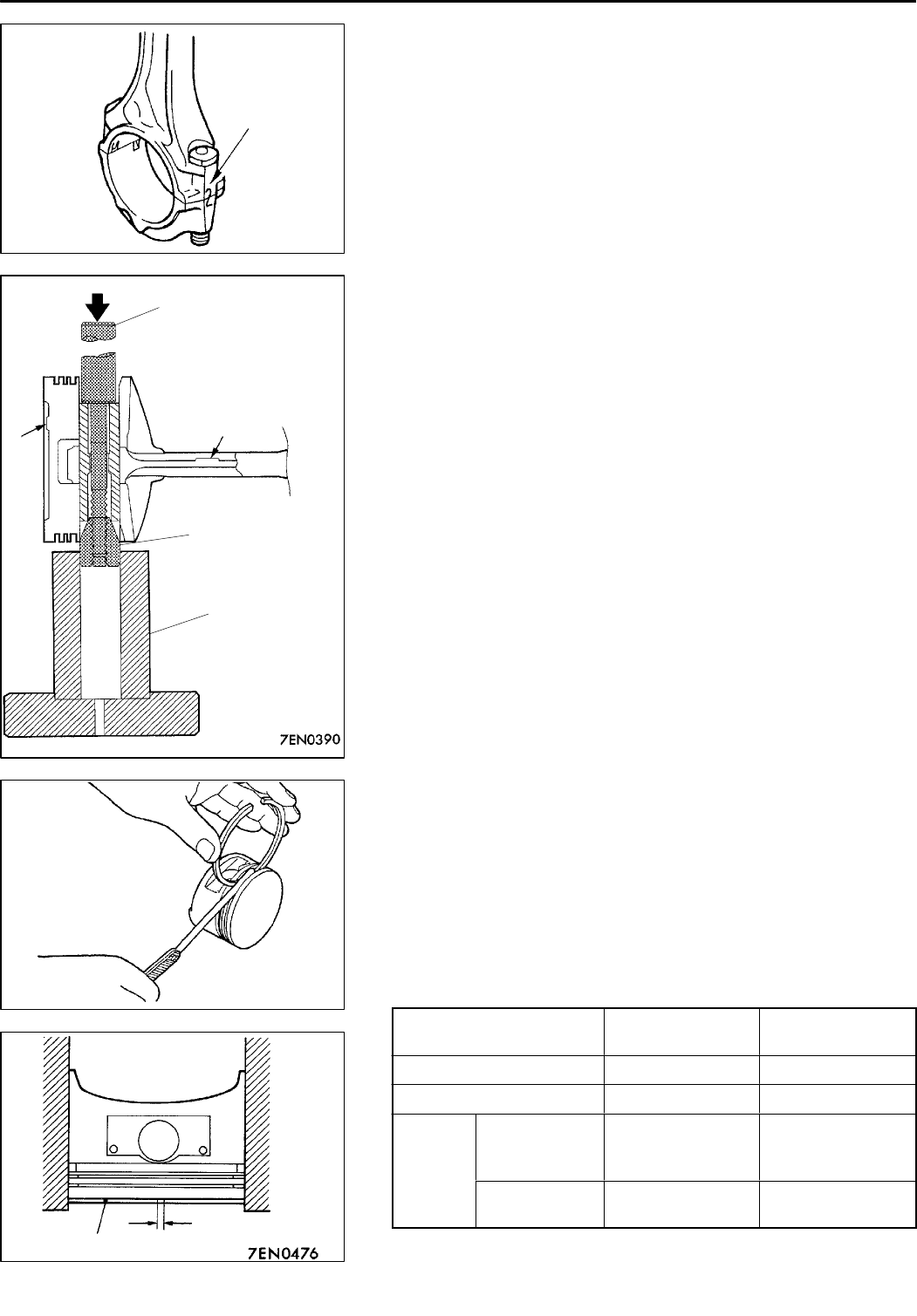

(2) Insert the piston ring into the cylinder bore and push

it down with a piston. Ensure that the piston’s crown

is in contact with the ring such that the ring is at 90

_

to the cylinder wall. Then, measure the en d gap with

a thickness gauge. If the gap is too large, replace the

piston ring.

Standard values

mm

Limits mm

No. 1 ring 0.20 - 0.35 0.8

No. 2 ring 0.35 - 0.50 0.8

Oil ring SOHC

12-VALVE,

DOHC

0.20 - 0.50 1.0

SOHC

16-VALVE

0.10 - 0.40 1.0

PWEE9520-A

E

Dec. 1998Mitsubishi Motors Corporation Revised

Cylinder No.

DEN0050

Push rod

Front

mark

Front mark

Guide D

Base

7EN0475

Push in with piston

Piston ring

End gap