4G1 ENGINE (E-W) -

Cylinder Head and Valves

11A-9-7

PWEE9520

E

Nov. 1995Mitsubishi Motors Corporation

VALVE SEAT CORRECTION SERVICE POINTS

(1) Before correcting the valve seat, check the clearance

between the valve guide and valve. If necessary, replace

the valve guide.

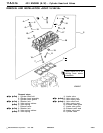

(2) Using the appropriate special tool or seat grinder, correct

the valve seat to achieve the specified seat width and

angle.

(3) After correcting the valve seat, lap the valve and valve

seat using lapping compound. Then, check the valve stem

projection (refer to 5. VALVE SEATS in INSPECTION).

VALVE SEAT REPLACEMENT SERVICE

POINTS

(1) Cut the valve seat to be replaced from the inside to reduce

the wall thickness. Then, remove the valve seat.

(2) Rebore the valve seat hole in the cylinder head to match

the selected oversize valve seat diameter.

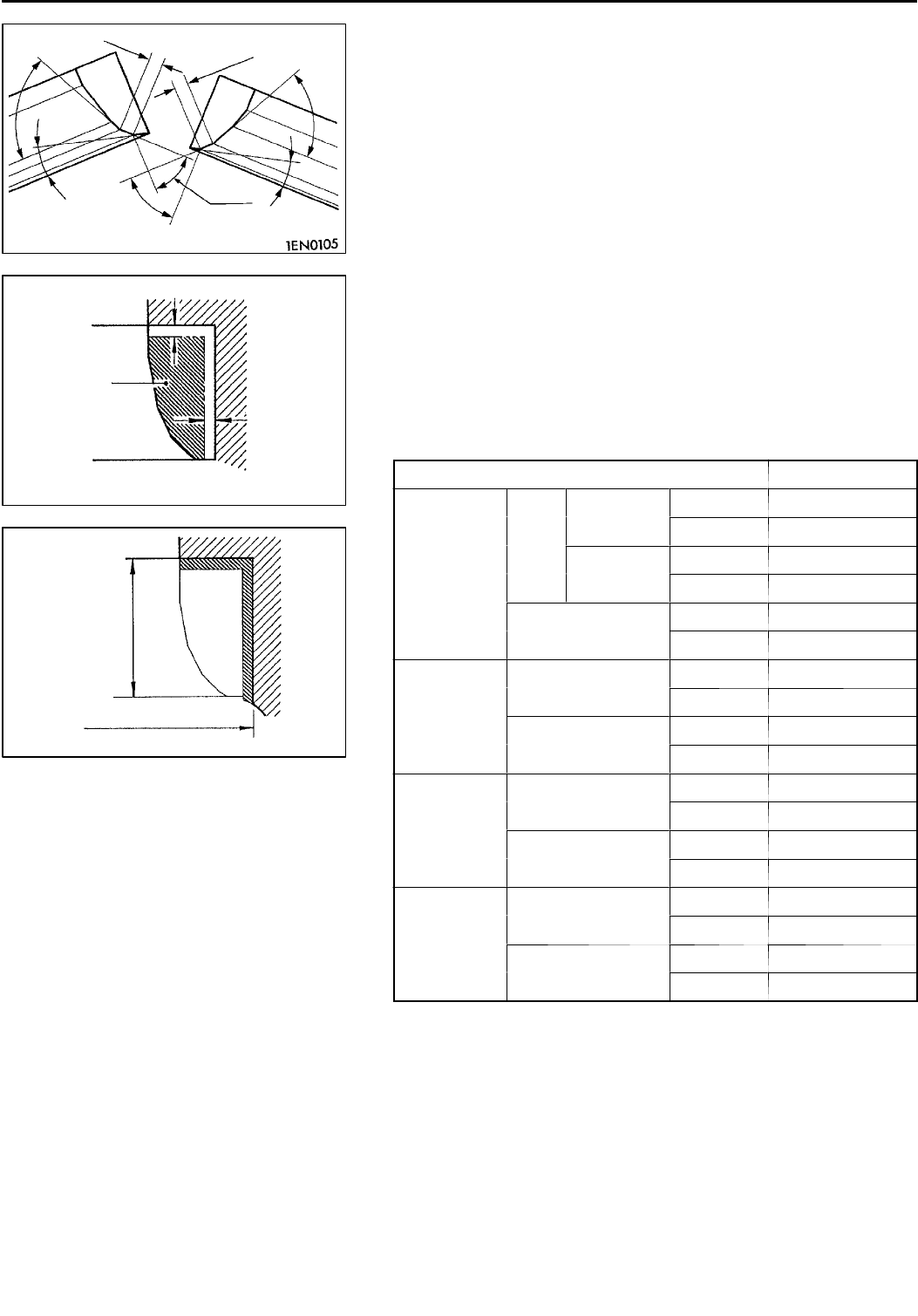

Valve seat diameters

Standard mm

SOHC In- Primary 0.30 O.S. 27.300 - 27.325

12-VALVE take

0.60 O.S. 27.000 - 27.625

Secondary 0.30 O.S. 32.300 - 32.325

0.60 O.S. 32.600 - 32.625

Exhaust 0.30 O.S. 35.300 - 35.325

0.60 O.S. 35.600 - 35.625

SOHC Intake 0.30 O.S. 28.300 - 28.321

16-VALVE

0.60 O.S. 28.600 - 28.621

<4G13>

Exhaust 0.30 O.S. 26.300 - 26.321

0.60 O.S. 26.600 - 26.621

SOHC Intake 0.30 O.S. 30.300 - 30.321

16-VALVE

0.60 O.S. 30.600 - 30.621

<4G18>

Exhaust 0.30 O.S. 28.300 - 28.321

0.60 O.S. 28.600 - 28.621

DOHC Intake 0.30 O.S. 31.300 - 31.325

0.60 O.S. 31.600 - 31.625

Exhaust 0.30 O.S. 27.800 - 27.825

0.60 O.S. 28.100 - 28.125

(3) Prevent galling of the cylinder head bore by cooling the

valve seat with liquid nitrogen before press-fitting it.

(4) Correct the valve seat to achieve the specified width a n d

angle (refer to VALVE SEAT CORRECTION SERVICE

POINTS).

PWEE9520-A

E

Dec. 1998Mitsubishi Motors Corporation Revised

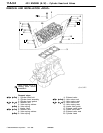

0.9 - 1.3 mm

0.9 - 1.3 mm

65

_

65

_

15

_

15

_

44

_

44

_

Cut away

1EN0274

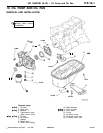

0.5 - 1.0 mm

0.5 - 1.0 mm

Valve seat

height

Oversize hole I.D.

1EN0275