4D68 ENGINE (E- W) -

Crankshaft, Cylinder Block and Flywheel

11A-12-6

(4) Bore all cylinders to the calculated boring finish dimension.

Caution

To prevent distortion that may result from temperature

rise during honing, bore cylinders, in the order of

No. 2, No. 4, No. 1 and No. 3.

(5) Hone to the final finish dimension (Piston O.D. + clearance

between piston O.D. and cylinder.)

(6) Check the clearance between piston and cylinder.

Clearance between piston and cylinder:

0.03 - 0.05 mm

NOTE

When boring cylinders, finish all of four cylinders to the

same oversize. Do not bore only one cylinder to an

oversize.

CYLINDER SLEEVE CHANGE PROCEDURES

REMOVAL

(1) Fix the cylinder block to a boring machine and center

it. Center at the lower portion of the cylinder sleeve where

there is less uneven wear.

(2) Bore to the sleeve wall thickness of about 0.5 mm.

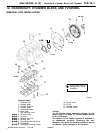

(3) Machine the screwdriveras illustrated and insert itbetween

the cylinder sleeve and cylinder block. Lightly hit it to break

the sleeve.

When doing so, be careful not to damage the cylinder

block wall.

PWEE9609

E

Dec. 1996Mitsubishi Motors Corporation

DEN238

P view

Round this surface

P

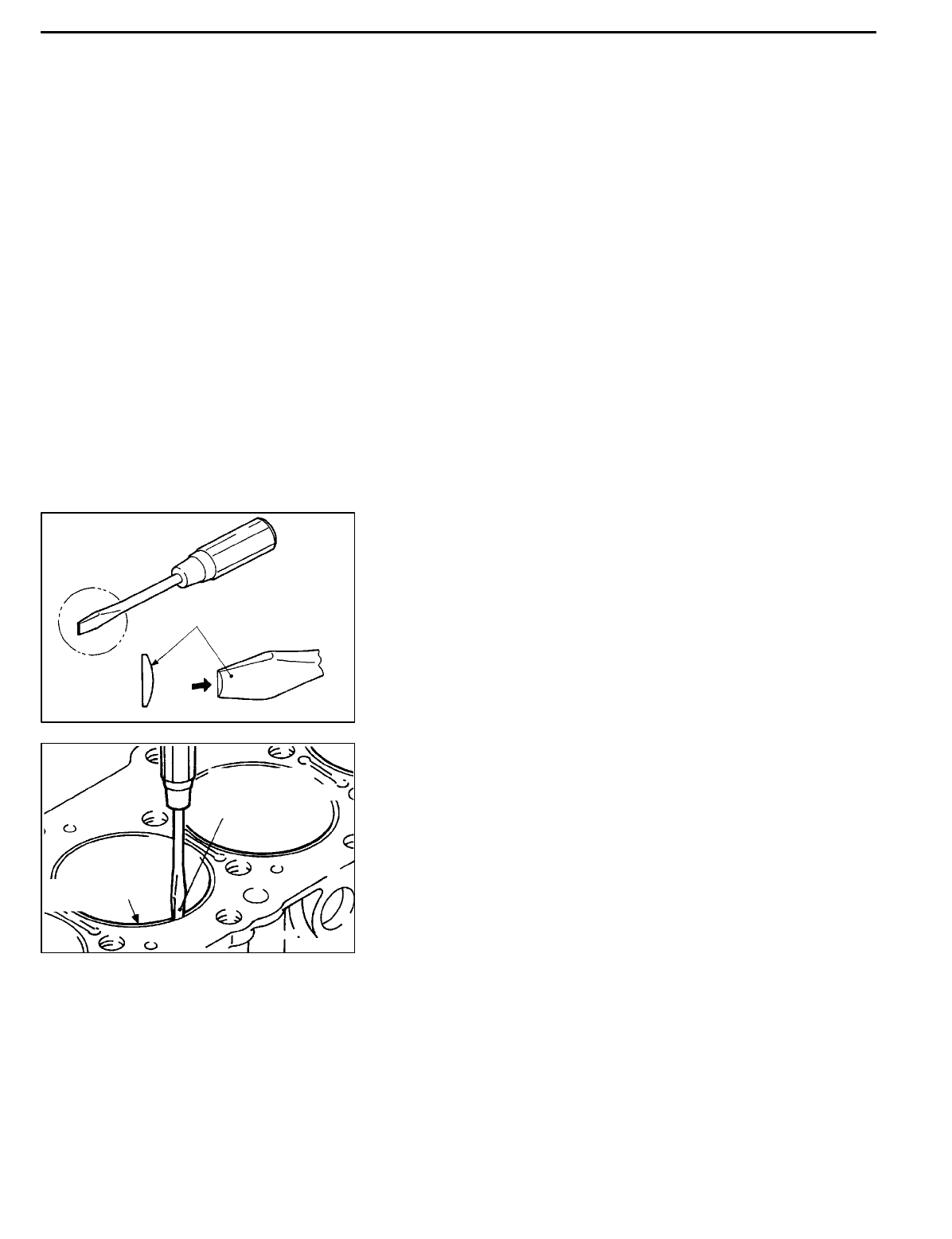

DEN239

Face round side

toward the cylinder

block

Thinned cylinder

sleeve