4D68 ENGINE (E- W) -

Cylinder Head, Valves and Valve Springs

11A-9-6

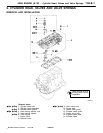

(2) Install the valve and, while pressing the valve against

the valve seat, measure the valve stem projection between

the valve stem end and the valve spring seat seating

surface.

Standard value: 43.45 mm

Limit: 43.95 mm

VALVE SEAT RECONDITIONING PROCEDURE

(1) Before correcting the valve seat, check the clearance

between the valve guide and valve. If necessary, replace

the valve guide.

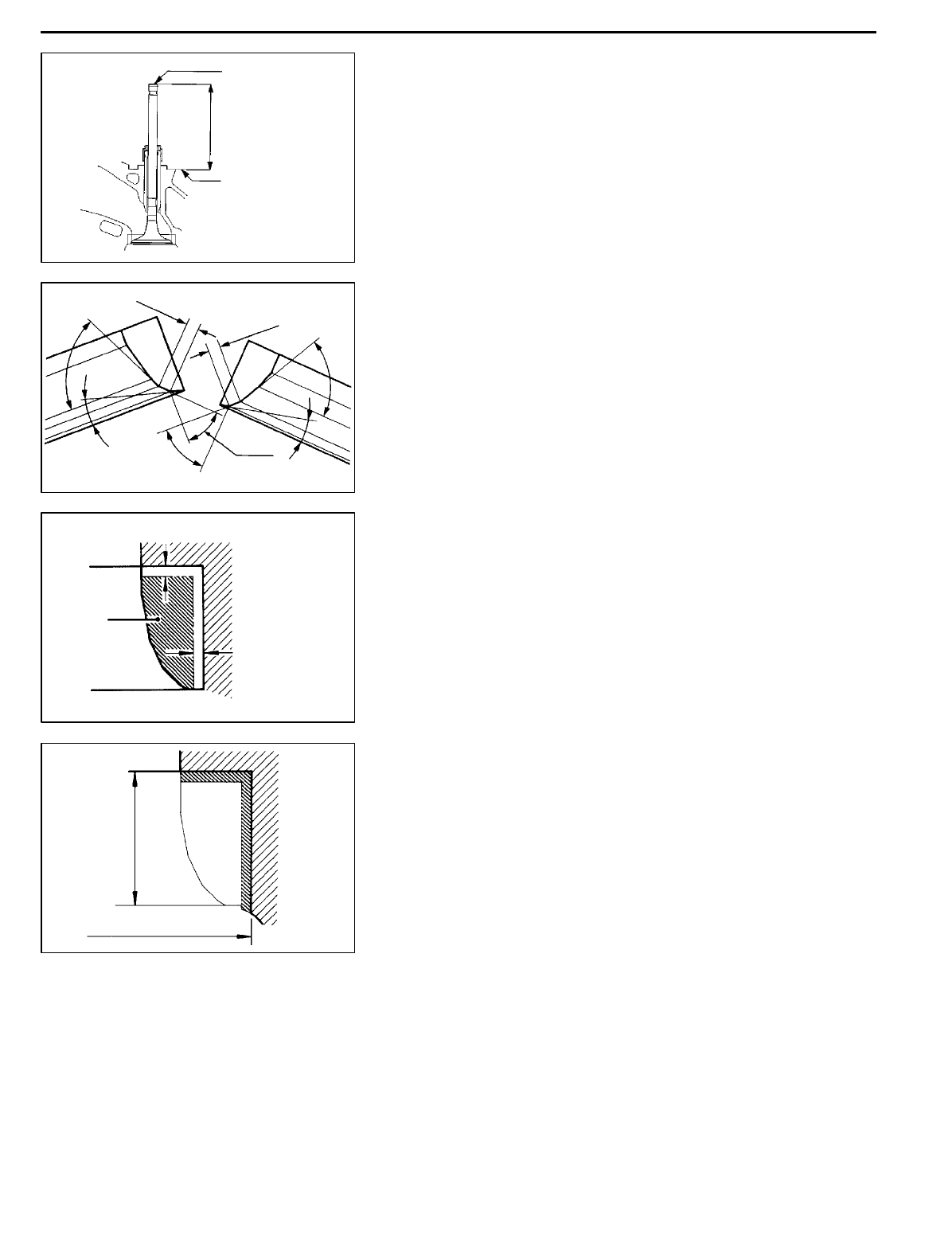

(2) Using the appropriate special tool or seat grinder, correct

the valve seat to achieve the specified seat width and

angle.

(3) After correcting the valve seat, lap the valve and valve

seat using lapping compound. Then, check the valve stem

projection (refer to 5. VALVE SE AT in INSPECTION).

VALVE SEAT REPLACEMENT PROCEDURE

(1) Cut the valve seat to be replaced from the inside to thin

the wall thickness. Then, remove the valve seat.

(2) Rebore thevalveseat holeinthe cylinderhead toaselected

oversize valve seat diameter.

Intake valve seat hole diameter

0.30 O.S.: 38.300 - 38.325 mm

0.60 O.S.: 38.600 - 38.625 mm

Exhaust valve seat hole diameter

0.30 O.S.: 34.300 - 34.325 mm

0.60 O.S.: 34.600 - 34.625 mm

(3) Before fitting the valve seat, either heat the cylinder head

up to approximately 25 0°C or cool the valve seat using

cooling spray, t o prevent the cylinder head bore from

galling.

(4) Using a valve seat cutter, correct the valve seat to the

specified width and angle.

See “VALVE SEAT RECONDITIONING PROCEDURE”.

PWEE9609

E

Dec. 1996Mitsubishi Motors Corporation

DEN0212

Valve stem end

Valve stem

projection

Spring seat seating

surface

1EN0105

0.9 - 1.3 mm

0.9 - 1.3 mm

65

°

15

°

44

°

44

°

15

°

65

°

1EN0274

0.5 - 1.0 mm

0.5 - 1.0 mm

Cut

away

1EN0275

Height of

seat ring

Oversize I.D.