4D68 ENGINE (E- W) -

Pistons and Connecting Rods

11A-11-5

INSPECTION

PISTON RING

(1) Check for side clearance.

If the limit is exceeded, replace the ring or piston, or both.

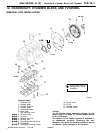

(2) In the case of semi-keystone type piston rings, check

the ring to ring groove clearance as illustrated.

Standard value:

No. 1 0.05 - 0.07 mm

No. 2 0.05 - 0.07 mm

Limit:

No. 1 0.15 mm

No. 2 0.15 mm

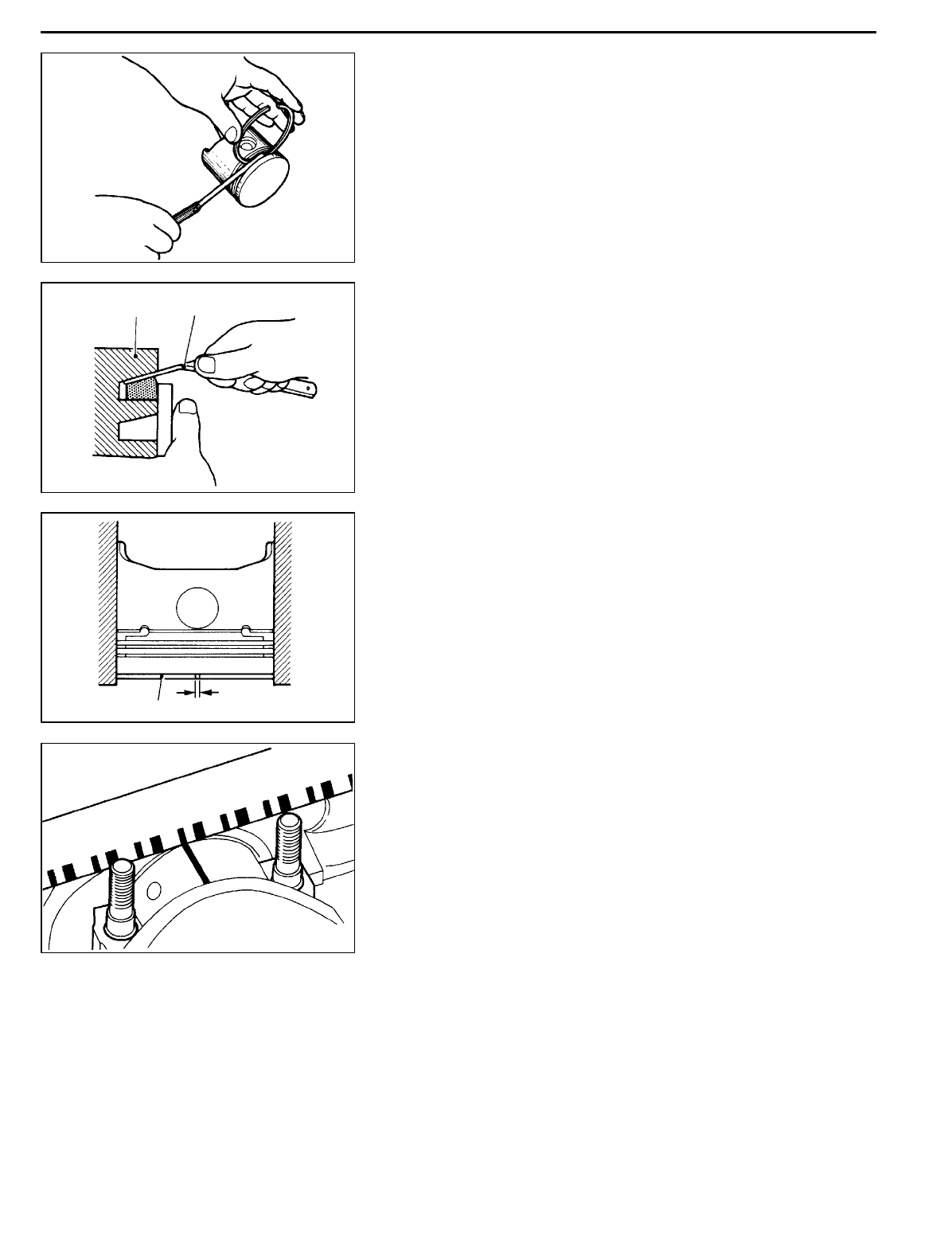

(3) Insert the piston ring into the cylinder bore. Force it down

with a piston, its crown being in contact with the ring,

to correctly position it at right angles to the cylinder wall.

Then, measure the end gap with a thickness gauge. If

the end ga p is excessively, replace the piston ring.

Standard value:

No. 1 0.20 - 0.32 mm

No. 2 0.35 - 0.50 mm

Oil 0.10 - 0.30 mm

Limit: 0.8 mm

CRANKSHAFT PIN OIL CLEARANCE (PLASTIC GAUGE

METHOD)

(1) Remove oil from the crankshaft pin and the connecting

rod bearing.

(2) Cut the plastic gauge to the same length as the width

of the bearing and place it o n the crankshaft pin in parallel

with its axis.

(3) Install the connecting rod cap carefully and tighten the

bolts to the specified torque.

(4) Carefully remove the connecting rod cap.

(5) Measure the width of the plastic gauge at its widest part

by using scale printed on the plastic gauge package.

Standard value: 0.02 - 0.05 mm

Limit: 0.1 mm

PWEE9609

E

Dec. 1996Mitsubishi Motors Corporation

5EN0066

DEN259

Piston

Thickness gauge

6EN0548

Press down ring

with piston

Piston ring

End gap

1EN0246