4D68 ENGINE (E- W) -

Cylinder Head, Valves and Valve Springs

11A-9-3

"

C

A

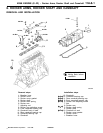

RETAINER LOCK INSTALLATION

(1) The valve spring, if excessively compressed, causes the

bottom end of the retainer to be in contact with, and

damage, the stem seal.

"

D

A

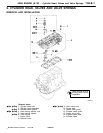

CYLINDER HEAD GASKET INSTALLATION

(1) In case any of the cylinder block, piston, connecting rod

and crankshaft has not been replaced, install the gasket

of the same rank as before which can be identified by

the mark shown in the illustration at left.

(2) In case any of the cylinder block, piston, connecting rod

and crankshaft have been replaced, reselect and install

the gasket in accordance with the following procedure.

1 With each piston held at the top dead center, measure

its protrusion from the upper block surface at the

locations shown in the illustration at left (total of eight

locations). Be sure to take measurements on the

crankshaft center line.

2 Using the average of the eight measurements, select

the gasket rank (A, B or C) in accordance with the

table given below. If, however, the maximum protrusion

at any one location exceeds the protrusion tolerance

shown for any rank in the following table, use the

gasket one rank higher that rank.

mm

Rank

Average value

of piston

protrusions

Protrusion

tolerance for

each rank

Thickness of

selected gasket

(when tightened)

A 0.641 - 0.700 0.750 1.40

±

0.05

B 0.700 - 0.760 0.810 1.45

±

0.05

C 0.760 - 0.823 - 1.50

±

0.05

"

E

A

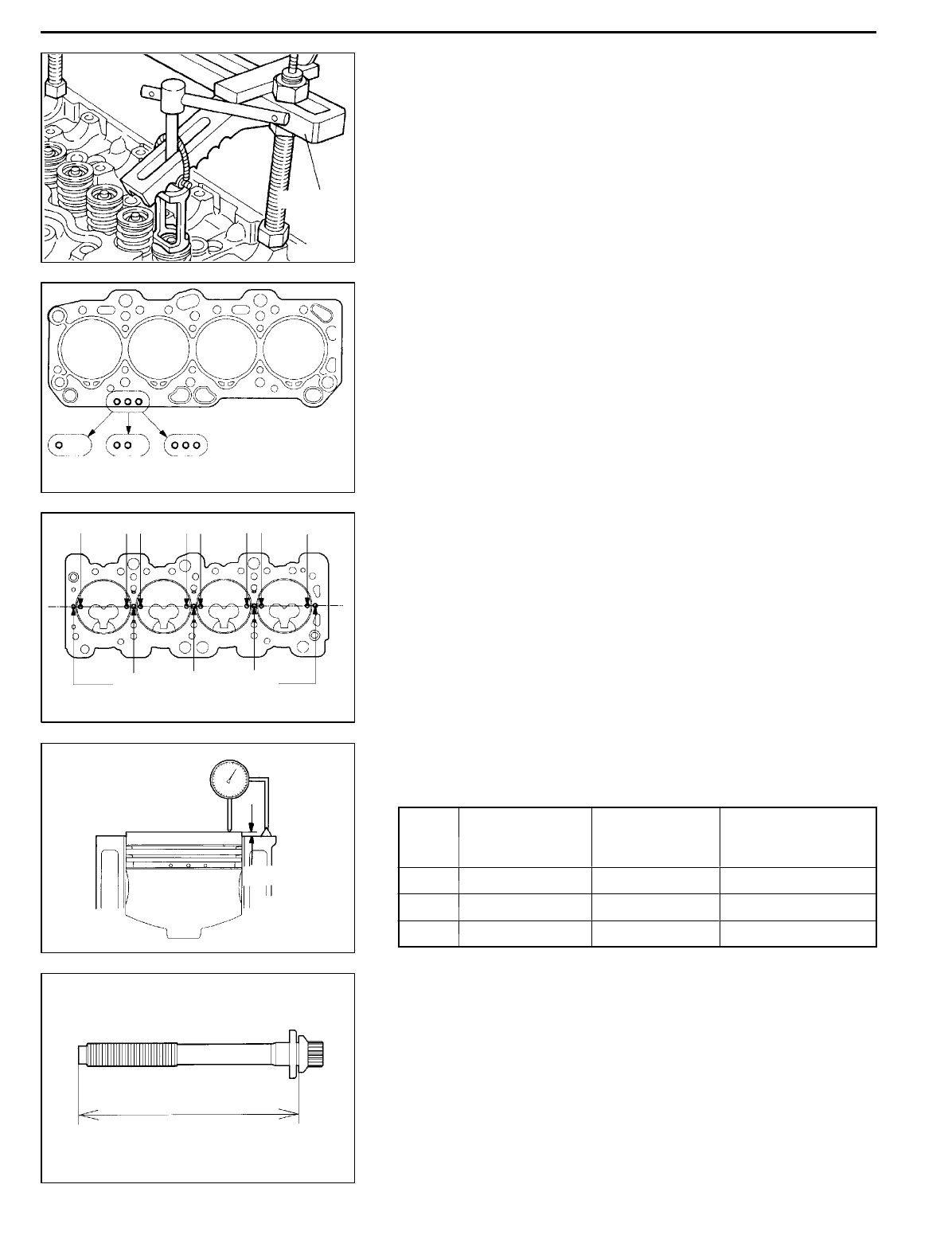

CYLINDER HEAD BOLT INSTALLATION

(1) When installing the cylinder head bolts, check that the

shank length of each bolt meets the limit. If the limit is

exceeded, replace the bolt.

Limit: max. 119.7 mm

(2) Apply engine oil to the bolt threads and washers.

PWEE9609

E

Dec. 1996Mitsubishi Motors Corporation

DEN0779

MD998772

DEN0796

Identification mark

Rank A Rank B Rank C

DEN0797

12345678

Protrusion measuring locations

(with each piston attop dead center)

Reference for measurement

DEN0798

Protrusion

6EN0782

Shank length